Package Structure of UV-C LED

Package Structure

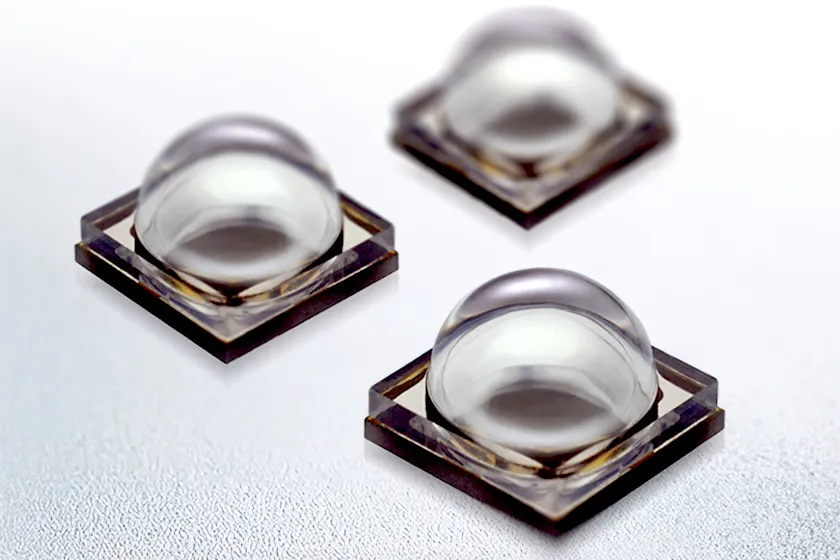

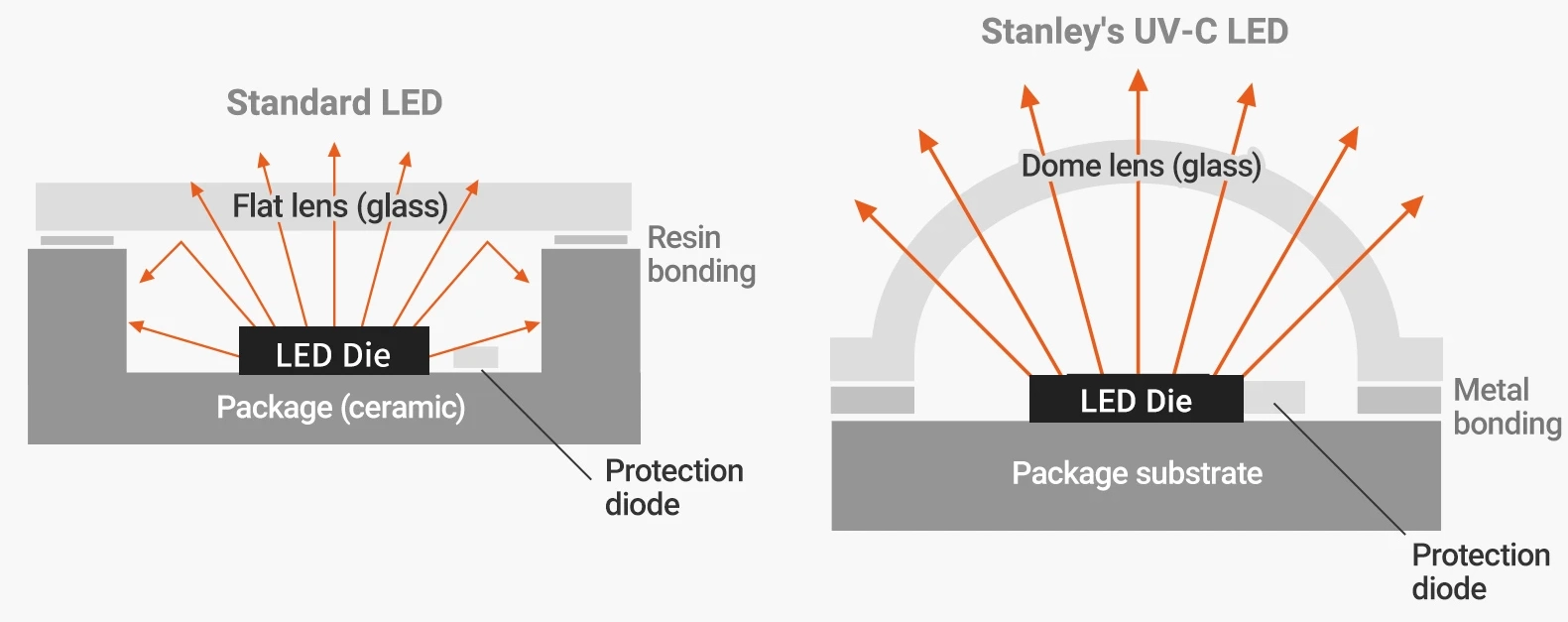

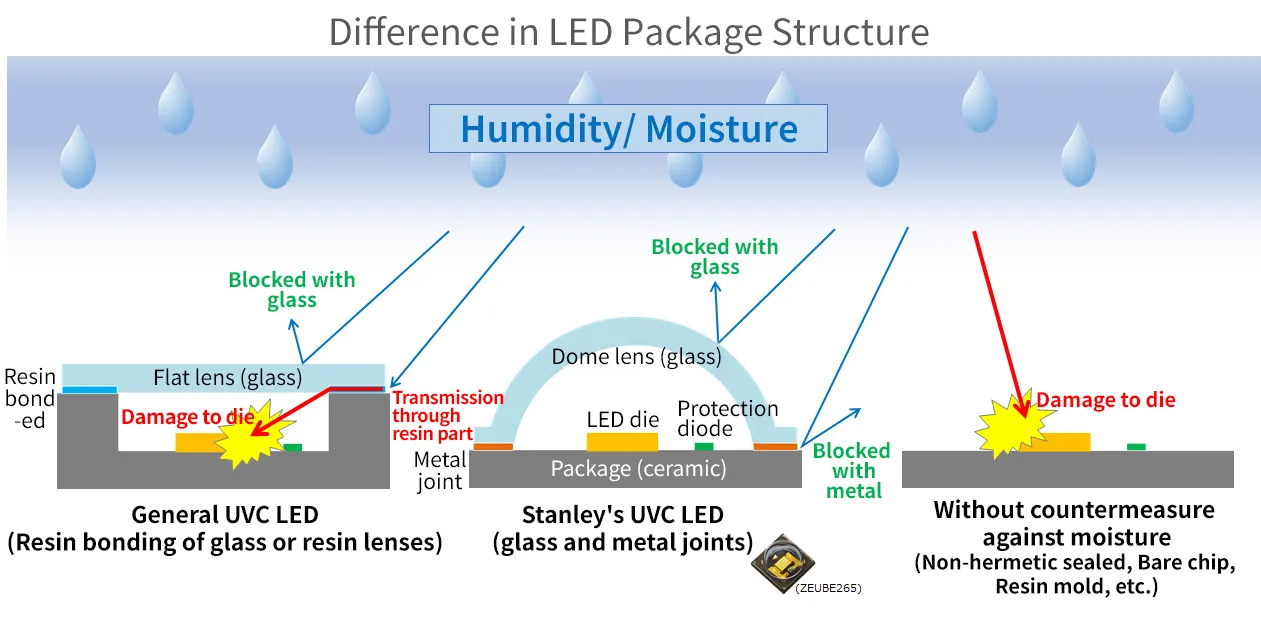

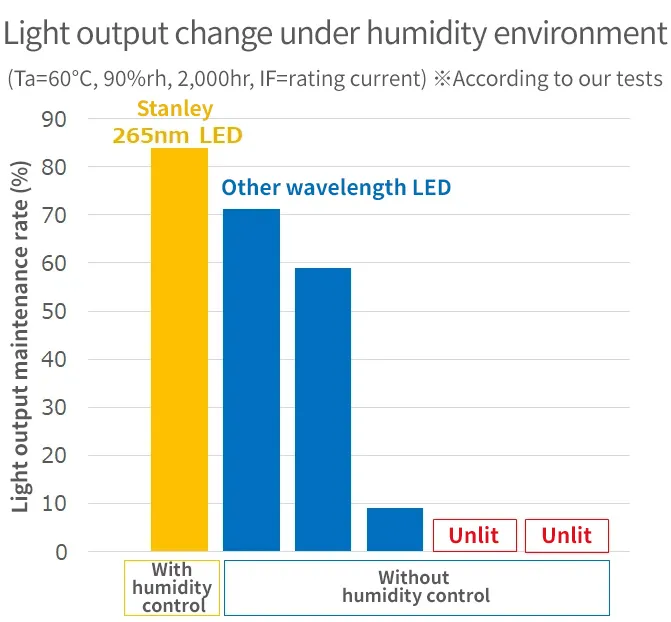

The LED package must allow light emitted from the die to be sent outside without as much loss as possible. Typically, LEDs use a method of bonding the substrate onto a flat-shaped glass lens. However, this causes significant loss of light and the package itself causes light from the die to be attenuated. Then Stanley's 265 nm UV-C LED uses dome-shaped glass. We can see that there is less light loss compared to flat glass. And UV-C LEDs are easily affected by the external environment and especially when moisture enters the package, there is a risk the LED will not turn on. Stanley's UV-C LEDs are not of the standard resin-bonded type. Instead the lens and package are joined and sealed with metal to block the inside and outside of the package and prevent moisture penetration [See Fig.1]. We also guarantee moisture-resistant operation for our products.

Figure 1 Illustration of Light Extraction Efficiency

Hermetically Sealed Package

UV-C LEDs are often used in water-related areas or in humid environments, and as they are easily affected by their surroundings, there is a possibility that they will fail to light up depending on the conditions of use. Our UV-C LEDs are devices that maintain reliability even after long periods of use in humid environments.

Long Lifetime

The combination of high-quality LED elements and highly reliable packaging achieves a long life of 10,000 hours at L70. (Based on our long-term current application test results for ZEUBE265)