Quality

Initiatives for Improving Quality

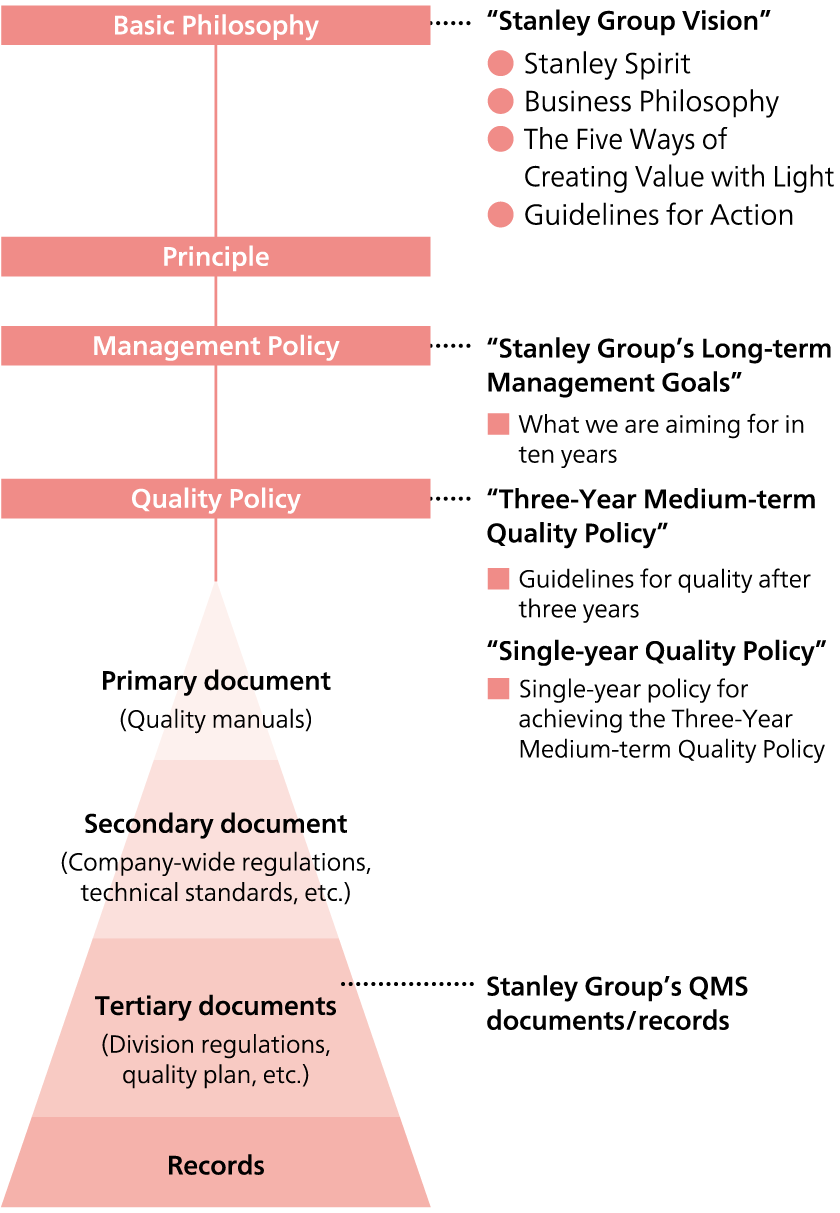

Our automotive equipment products are important safety components whose failure may be lifethreatening. We have established a system for quality management activities to ensure the safety and security of end users. We also formulated the “Principle” as second in importance only to our Basic Philosophy. It defines the basic principles that are top priority for our quality management on which all employees of the Group should base their decisions and actions. As described above, “Safety and Quality” is the most important and fundamental precept to the Group, which is given priority over our management policy. We offer education and training sessions to ensure this Principle is made known to not only new hires but all employees. The Principle is also recited every day in an attempt to ensure it permeates the entire Group.

【Principle】

As a manufacturer of important safety parts,

we focus on fundamentals in all our day-to-day

operations to reliably supply safe products.

We are driven by the motto

Don't

buy

make

pass on

defects

Every day, we rise to the challenge of pursuing excellence

in manufacturing.

Quality Management System

Each of our sites has obtained certification for both ISO 9001, the international standard for quality management systems, and IATF 16949, a specialized standard for the automotive parts industry. And we have constructed a management system that meets the strict requirements necessary for automotive components

| ●ISO9001 | :11 sites in Japan/8 sites overseas |

|---|---|

| ●IATF16949 | :9 sites in Japan/16 sites overseas |

Quality Awareness Activities

We develop products with due consideration to safety and provide customers with such products. In cases when we receive any safety-related information, we immediately confirm the fact, and if it turns out that any safety issue is present, we report it to the departments and people concerned in house, and take prompt and sincere responses to identify the cause and prevent the expansion of accidents and re-occurrence.

QE Circle Activities

Our Group is also rolling out Quality Education (QE) circle activities, which are improvement activities for small groups. These activities are part of a bottom-up approach to improving quality, and are being implemented not only by members on the production line, but by all employees, including those involved in development, design, and head office functions

Quality Learning Corner

We have established a Quality Learning Corner in our design offices as a place where employees can learn about quality problems, and make sure that past quality problems are not repeated. In the Quality Learning Corner,lessons learned from past problems with quality are consistently passed on the new generations, leading to improvements in the quality of new products