Light Distribution Technology of Water Disinfection Reactor

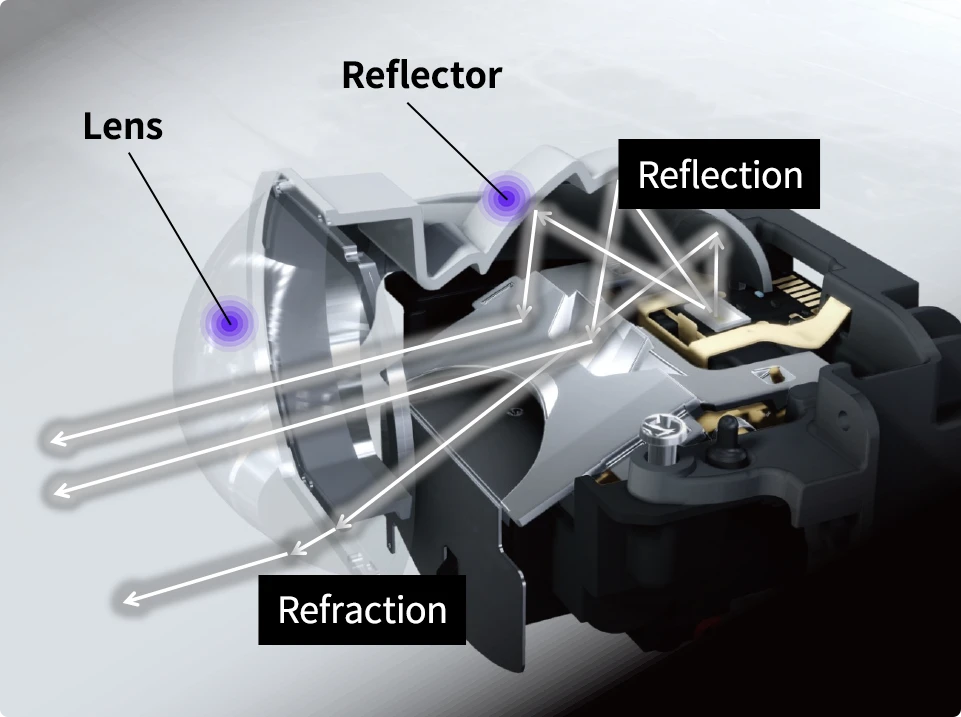

Reflection and Refraction in Optical Control

Light goes straight as long as there are no obstructions but it has properties of refracting when there are areas with different densities in the path of the light. The reason you can see light deformed above an asphalt road on a hot summer day is due to the phenomena in which light is refracted when air density changes because of the rise in temperature. These properties of light are used by refractive optical systems that make use of lenses. Depending on the incident angle and exit angle of light entering and leaving the lens, the angle of refraction can be freely adjusted to bend the light. Moreover, a reflector uses a shiny surface to change the angle by reflecting the light that was moving in a straight line. In this fashion, the properties of an optical system referred to as refraction and reflection are used to create light distribution *1.

- Light distribution is the appropriate distribution of required light for a location where it should reach.

Fig.1: An Image Showing Reflection and Refraction for a Headlamp Light Source Unit

Using Light Distribution Technology Developed for Automotive Headlamps

We have conducted a simulation of the design and used suitable parts and materials to freely control light. The ability to create light by combining optimal types and sizes of parts and materials to meet the needs and applications is a strength of Stanley Electric in the field of light distribution technology.

The development of Adaptive Driving Beam (ADB) is progressing rapidly as a headlamp technology in recent years. ADB is a technology that controls light when there are pedestrians and drivers in front of you to control and beam the required amount of light in places where it is needed. This technology enables the driver to always drive with the high beam turned on without causing trouble for other drivers such as dazzling them. Stanley Electric also deals in outdoor lighting and street lighting. Light pollution (various impact that occurs because there was insufficient consideration for the landscape and surrounding environment due to inappropriate light distribution and methods used to install lighting) is regarded as a problem in this field. Therefore, technology in terms of freely controlling light to distribute light optimally to only those places where it is needed is being used for outdoor and street lighting.

Light Distribution Technology for UV-C Products

Light distribution technology is applied in the development of UV-C products. Ultraviolet light can disinfect bacteria and viruses while at the same time may also have an adverse effect on the human body. Different to visible light, ultraviolet light is not visible to the human eye so we cannot consciously avoid it. Stanley Electric freely controls UV-C irradiation using technology that optimizes light distribution to achieve the safe use of UV-C light sources.

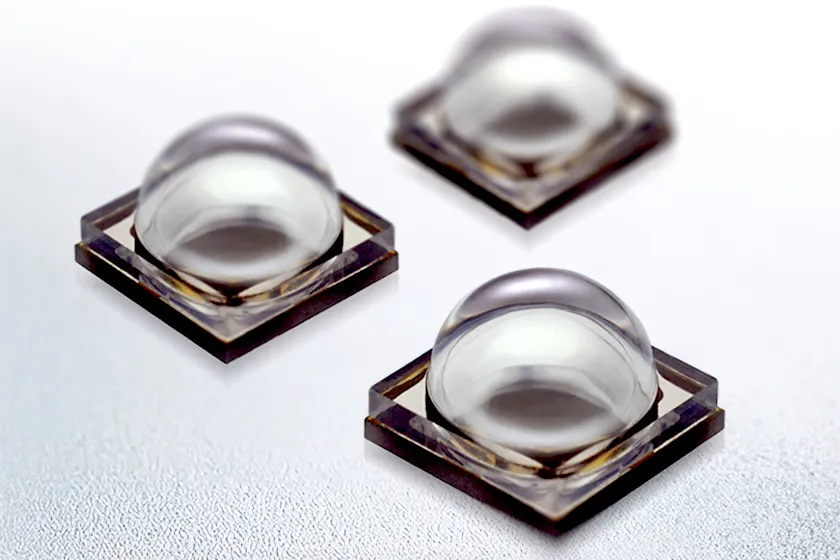

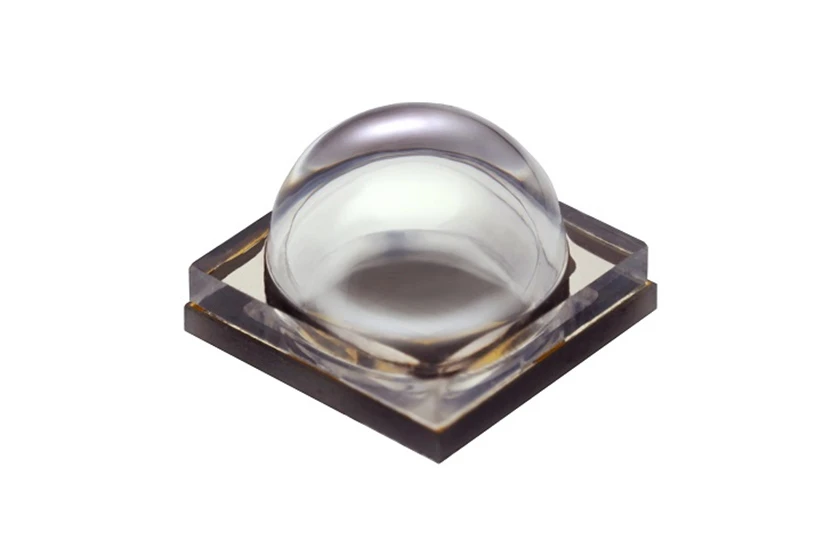

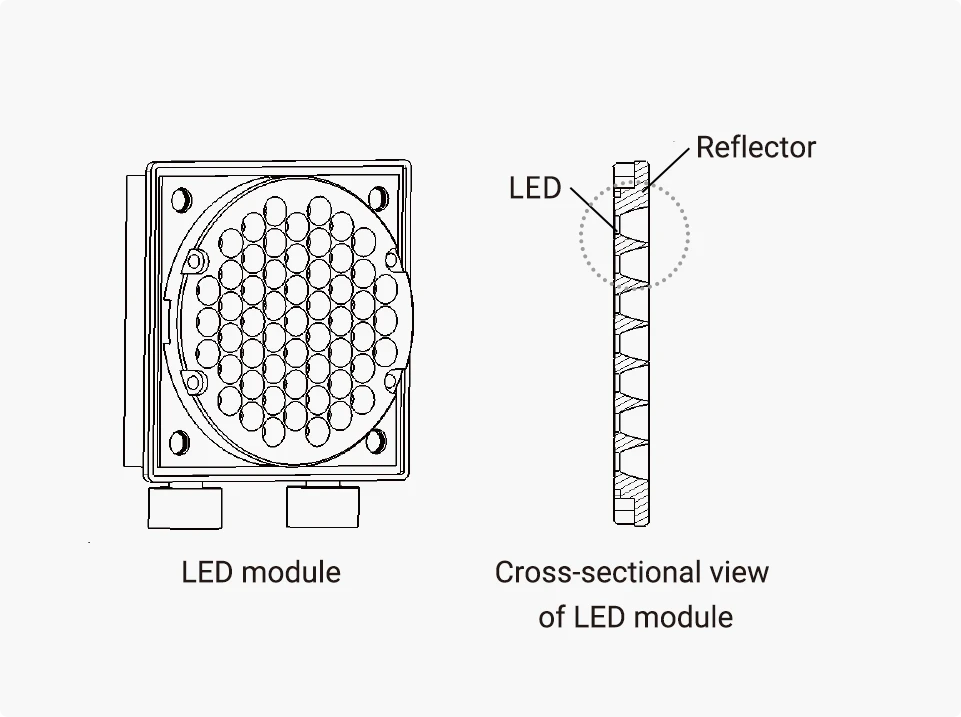

A difference with automotive headlamps that use light distribution technology for UV-C products, is not possible to use resin(deteriorates due to UV)-based lenses. So reflector technology is important in controlling irradiation in the UV-C product.

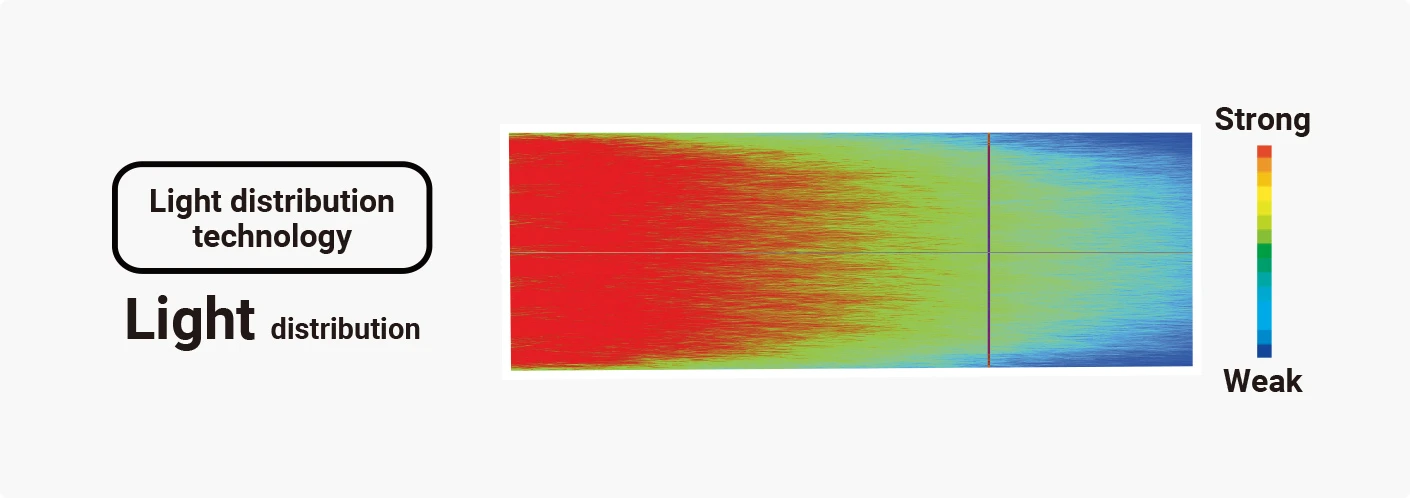

For example, in the UV-C LED reactor equipped with many LEDs, the light is diffused over a wide range and it is not possible to control the irradiation, when only LEDs are used. This is where a mechanism is used that can control the light distributed from each LED to uniformly irradiate UV-C and disinfect such as water that flows into the pipe by optimally arranging a reflector together with many LEDs [See Fig.2].

Fig.2: Optical Structure of UV-C LED Reactor

Fig.3: UV-C LED Reactor Irradiated Surface

A Consistent Design and Production System from Light Sources to Modules and Finished Products

In addition to the technology mentioned above, factors such as the light source shape, size and characteristics have an impact on the light distribution. Therefore, the ability to consistently in-house design and produce items from light sources to modules and finished products to match product characteristics while verifying such items is a strength of Stanley Electric and we believe it will continue to work to our advantage. We are also focusing on technology that improves the conversion efficiency of light and fine chromatic control that produces bright light, and have been contributing to such things as reducing carbon dioxide and power consumption when it comes to the global environment. Using our technical capability developed for automotive headlamps and wealth of experience, as well as our consistent design and production system, Stanley Electric will continue to promote technological innovation for light into the future to create new light that is useful to society.

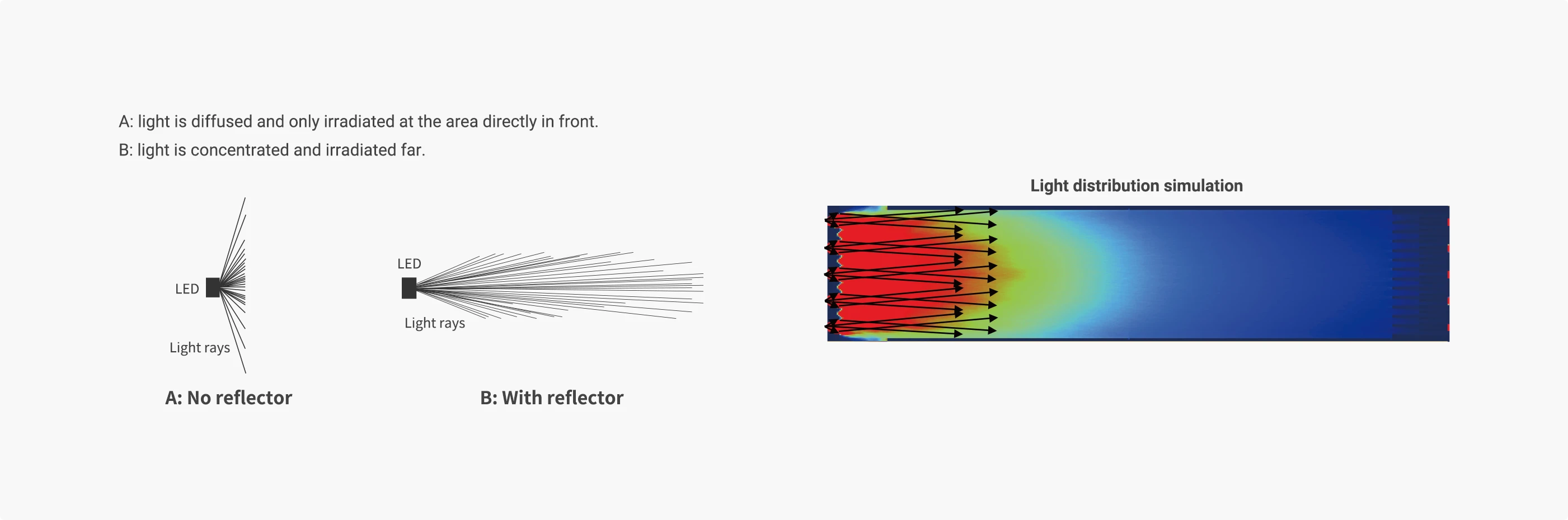

Irradiation Simulation

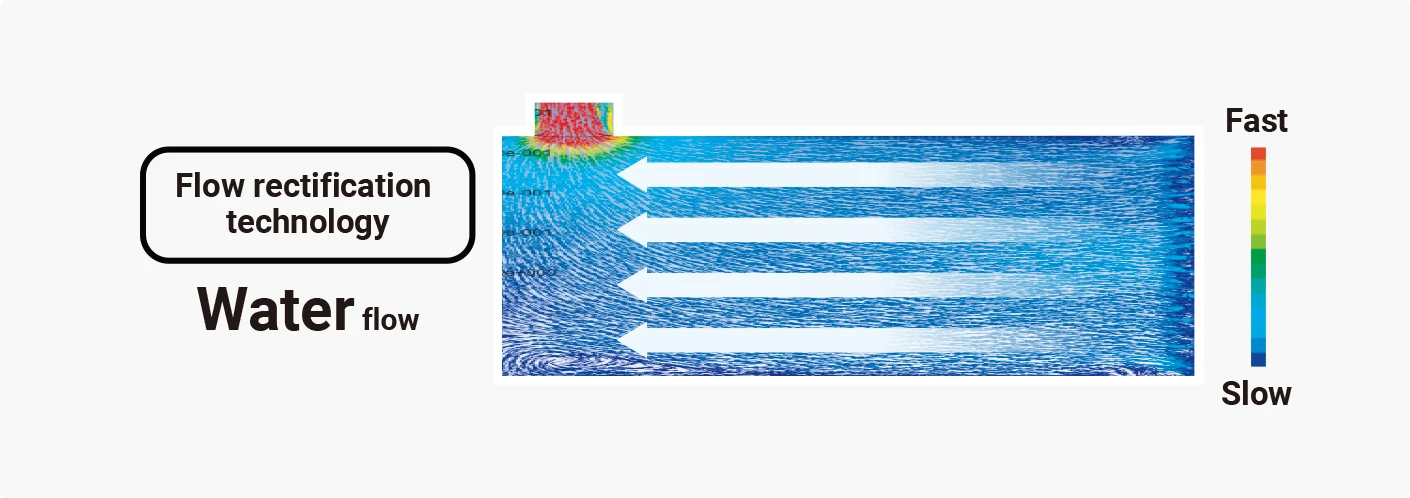

Stanley Electric simulates reactor's disinfection to optimize its efficiency (the size, light source type and quantity, etc.) and rectify the reactor's water flow inside, based on the customer's running water conditions.

We also offers optimized disinfection driving conditions to prolong the life of the reactor and to save energy.

-

Achieving a uniform flow rate that reduces water speed using a flow rectification mechanism

Water flow has been rectified. (Vector direction and color) -

Effective irradiation of UV-C light using light distribution technology developed for automotive headlamps

Light distribution to ensure light from the LED hits no part of the pipe wall except the reflector. (Distribution of light strength)

Disinfection Effect

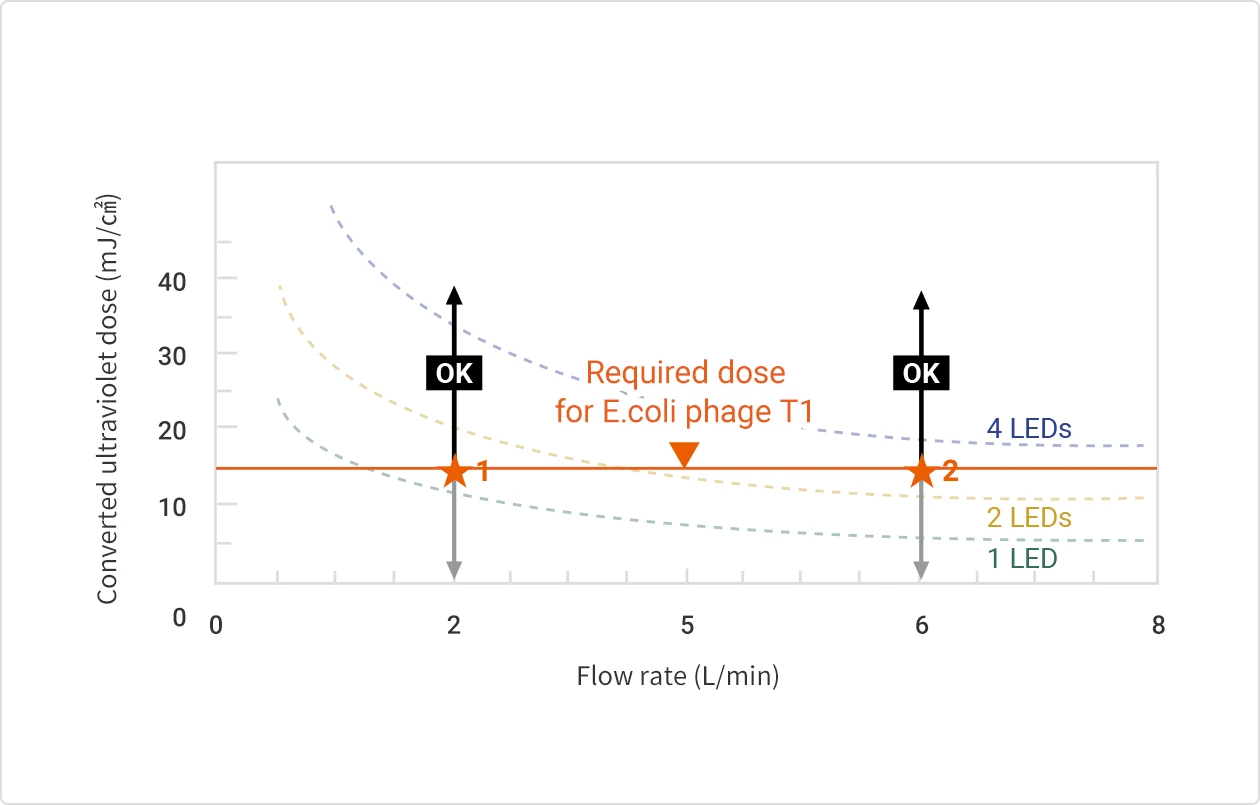

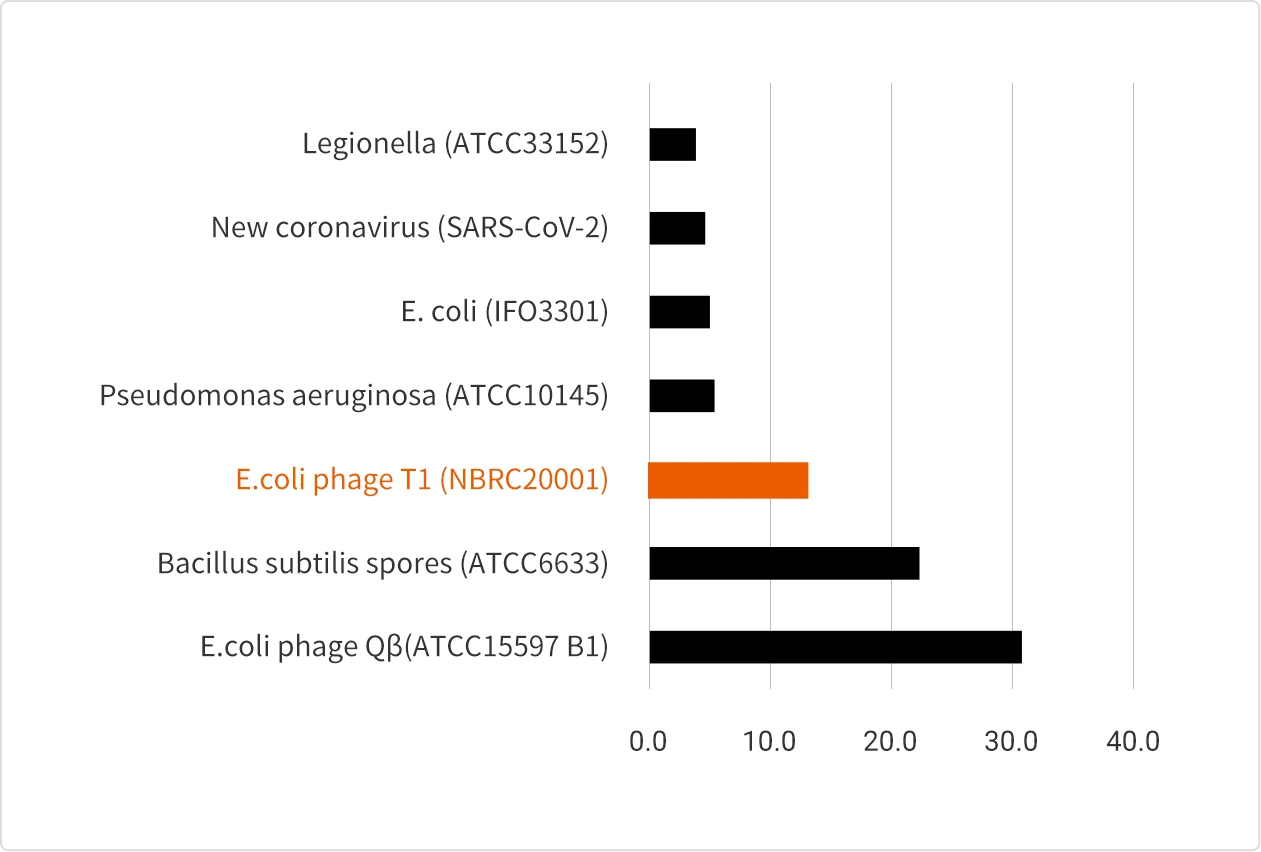

The required dose varies depending on the type of bacteria and virus to be disinfected. To disinfect 99.9% of E.coli phage T1, the required dose is 12.9 mJ/㎠ (based on test results at Stanley Electric).

Fig.6: Dose Required for 99.9% of Disinfection

The greater the flow rate, the more light sources (LEDs) are required inside the reactor. For a flow rate of 2 liters, the required dose of 12.9 mJ/ can be obtained as long as the reactor has two or more LEDs (★1). For a flow rate of 6 liters, four or more LEDs are required (★2).

Fig.7: Graph Showing Performance by Number of Light Sources