Surface and Air Disinfection with UV-C Light

Surface Disinfection (Direct Irradiation)

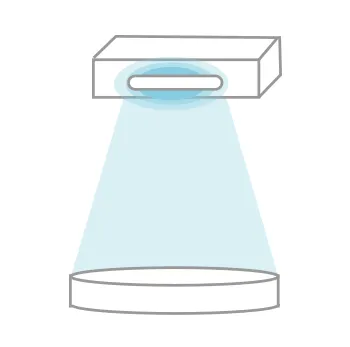

Basic Structure of Surface Disinfection

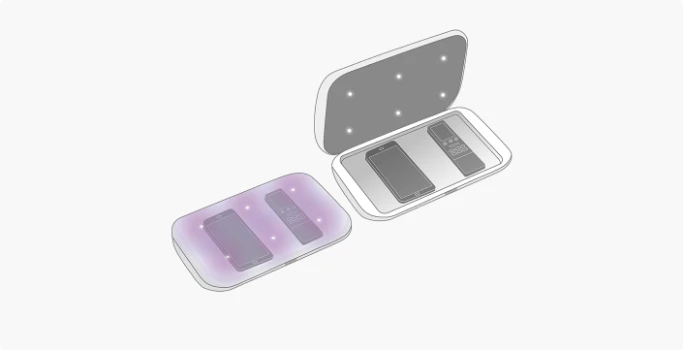

Surface disinfection is directly irradiating the surface of an object with UV-C. In comparison to water and air disinfection, it is expected that surface disinfection will cover a wide range of objects such as door knobs, smartphones, computer keyboards and tables.

| Light source | Surface disinfection (direct irradiation) |

|---|---|

| UV-CCL UV-LED |

|

| Applications | Disinfection of small objects such as masks and smartphones, disinfection of operation terminals such as touch panels and keyboards, disinfection of containers and packaging material |

| Advantages | Can keep clean places that may be directly touched by human hands. |

Irradiation Simulation

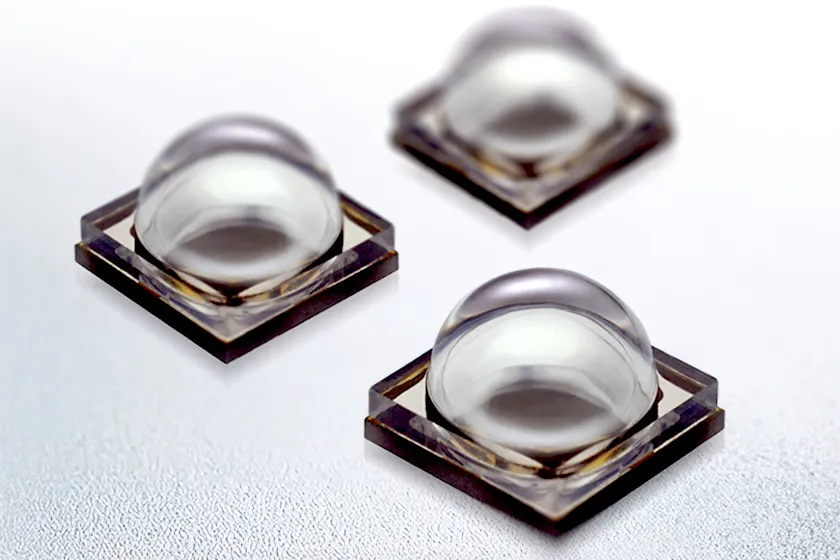

The effect of disinfecting surfaces is determined by the distance from the light source and the irradiation time when the light output power is the same. Stanley Electric will offer UV Light Sources that meet the customer's needs, usage conditions and purpose after conducting irradiation simulations considering factors such as the UV Light Source type, quantity, installed location, and the deterioration of irradiated parts and materials.

-

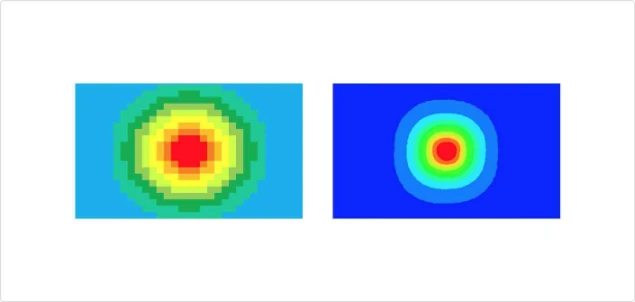

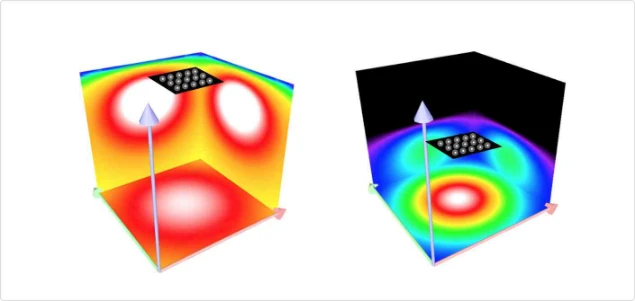

Irradiation Characteristics for A Single Light Source

Extensive support from simple calculations to simulations using light source data

-

Irradiation Characteristics When Combining Multiple Light Sources

Intensity distribution depending on the light source locations

Disinfection Effect

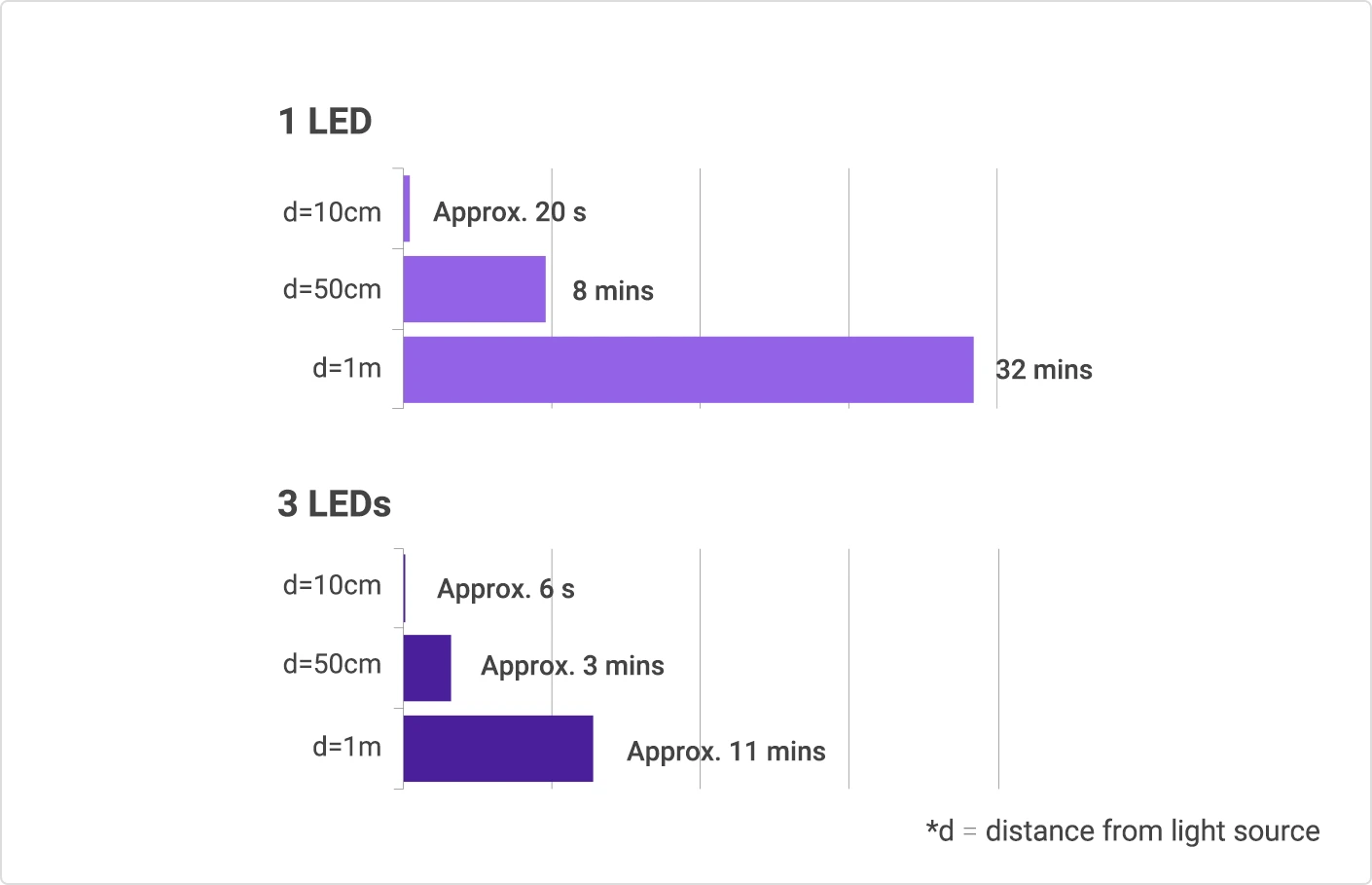

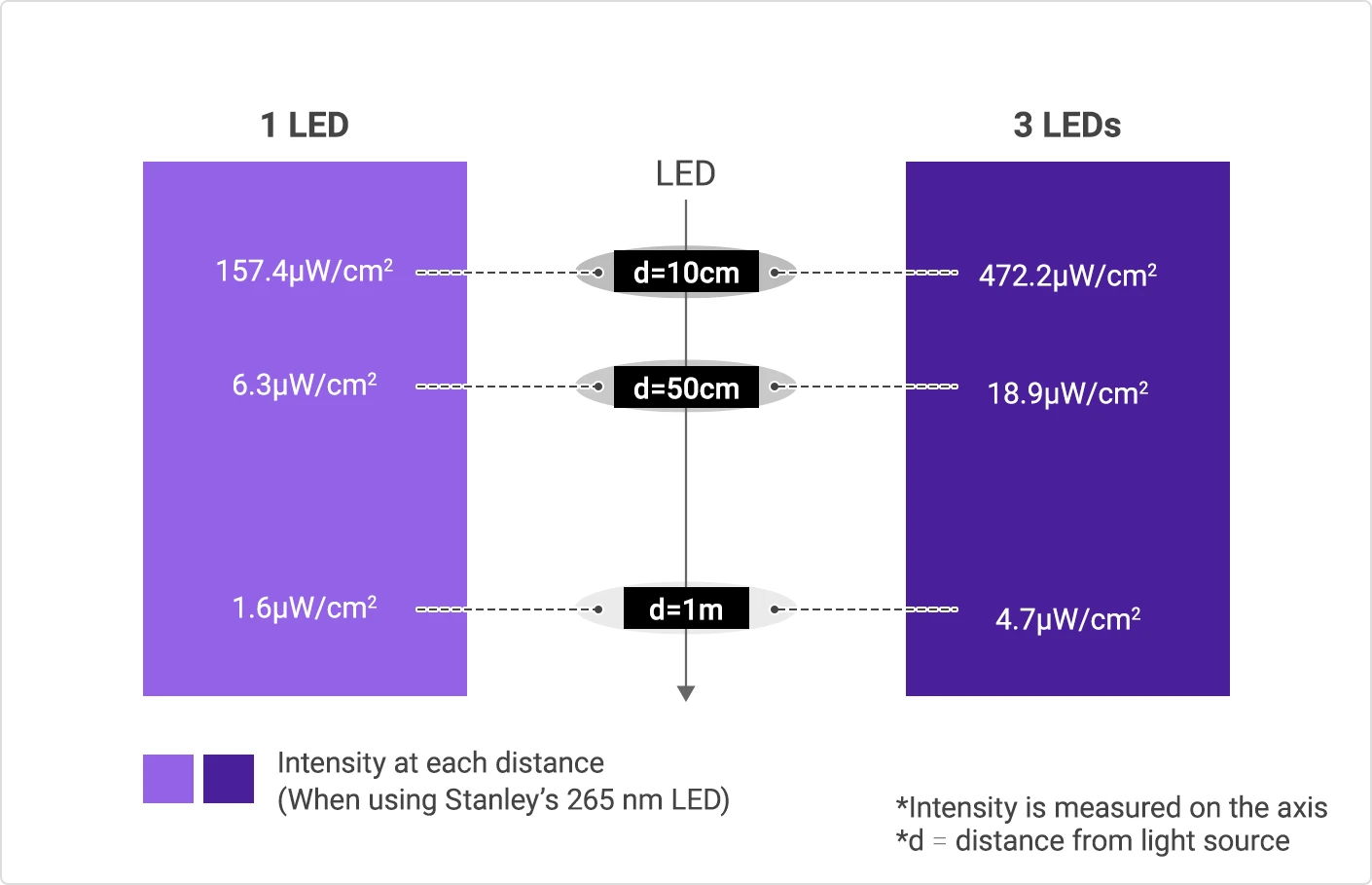

The closer from UV-C light source, the more intensity, then to obtain the same disinfection effect for objects at different distances from the light source, the required time to irradiate ultraviolet changes. [Fig.1] and [Fig.2] each show the time required for disinfection and the intensity by distance, when using one LED and three LEDs respectively at 265 nm/50 mW to disinfect 99% of the new coronavirus.

-

Fig.1: Change in Disinfection Time by Distance

-

Fig.2: Comparison of Intensity by Distance from The UV-C LEDs

Air Disinfection (Circulation Type)

Basic Structure of Air Disinfection

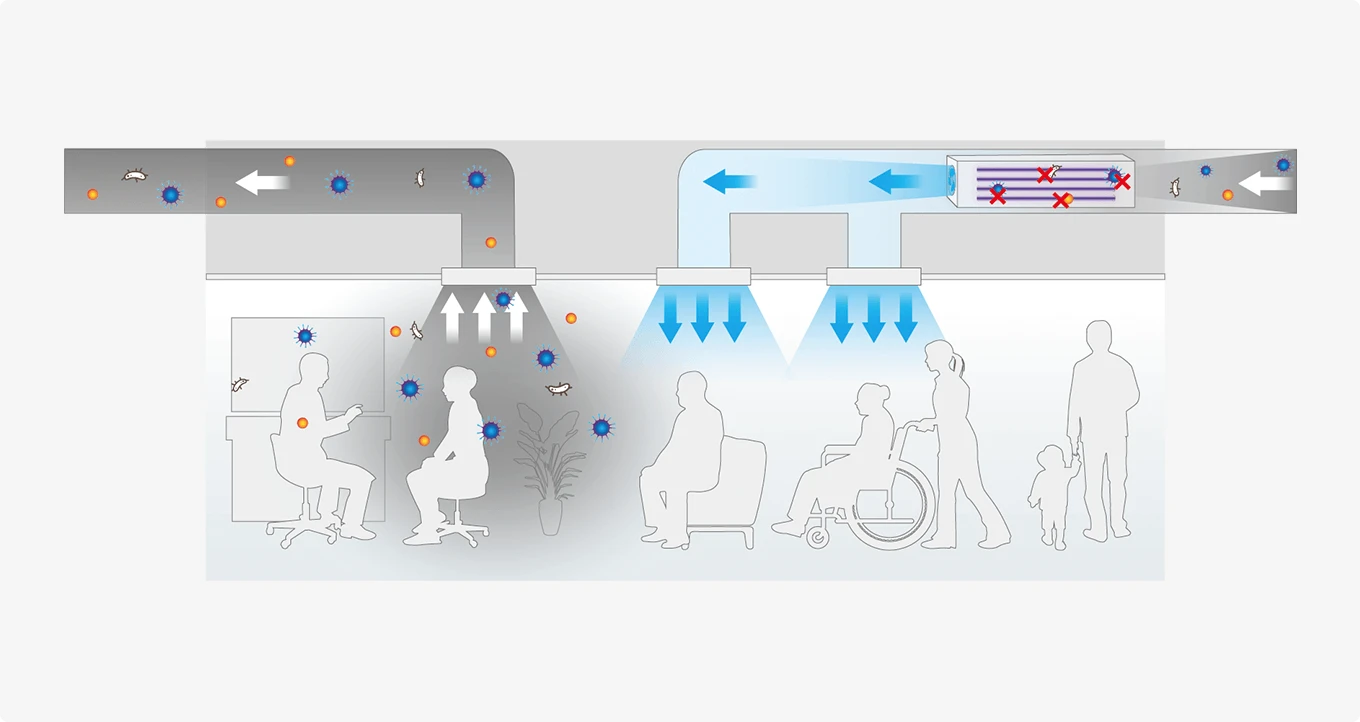

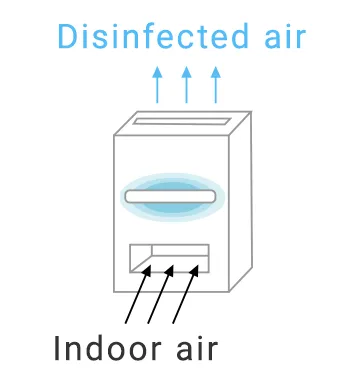

A circulation method is often used for air disinfection in which air taken in from a specific enclosed space is disinfected by irradiating UV light on it directly and then clean air is supplied outside Recently, air purifiers with UV light in various sizes have been released to the market for use indoors in such places as hospital waiting rooms, as well as compact air purifiers for use in small spaces such as inside vehicles.

| Light source | Air disinfection (circulation type) |

|---|---|

| UV-CCL UV-LED |

|

| Applications | Air conditioning systems, disinfection in each area of a nursing home, hospital, etc., disinfection for entire buildings and clean rooms, etc. |

| Advantages | Bacteria in air taken in by the equipment is directly irradiated with ultraviolet light to enable indoor purification at a high disinfection rate. |

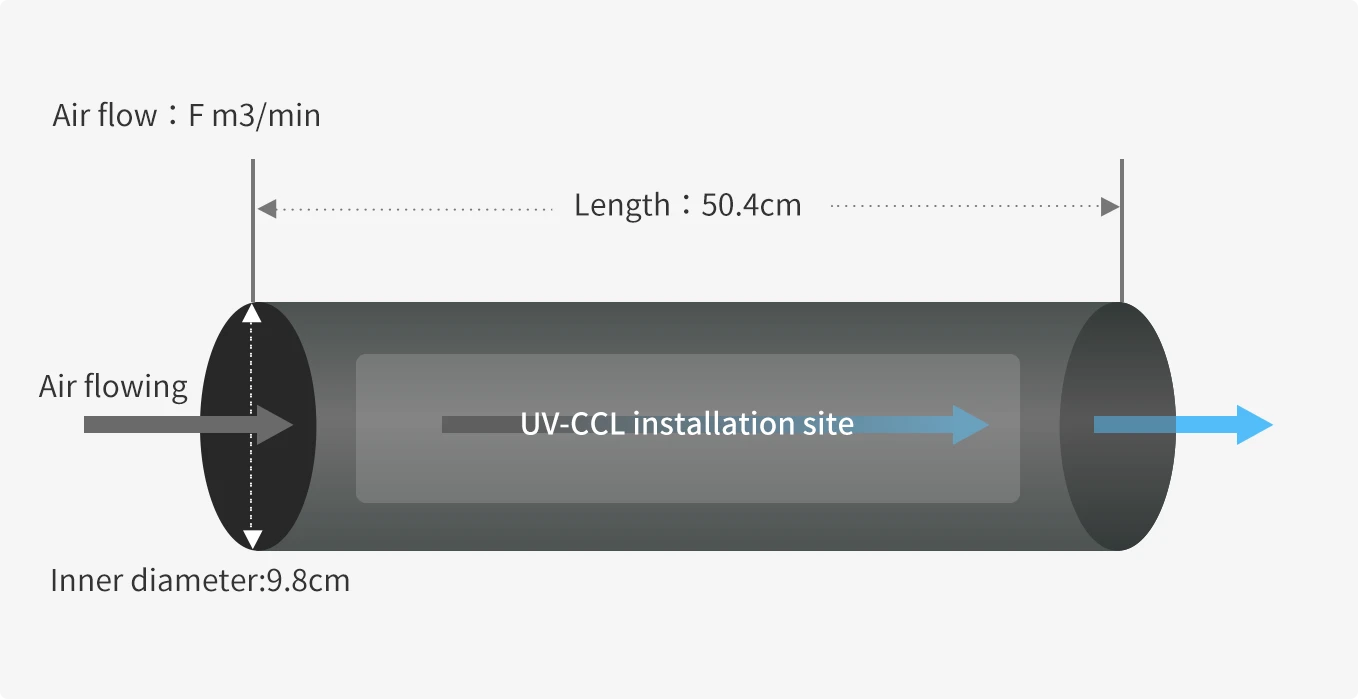

Fig.3: An Image Showing UV-CCL Installation

Disinfection Effect

For circulating air disinfection systems, the disinfection effect and necessary time changes depending on the amount of air flow and the number of ultraviolet light sources.

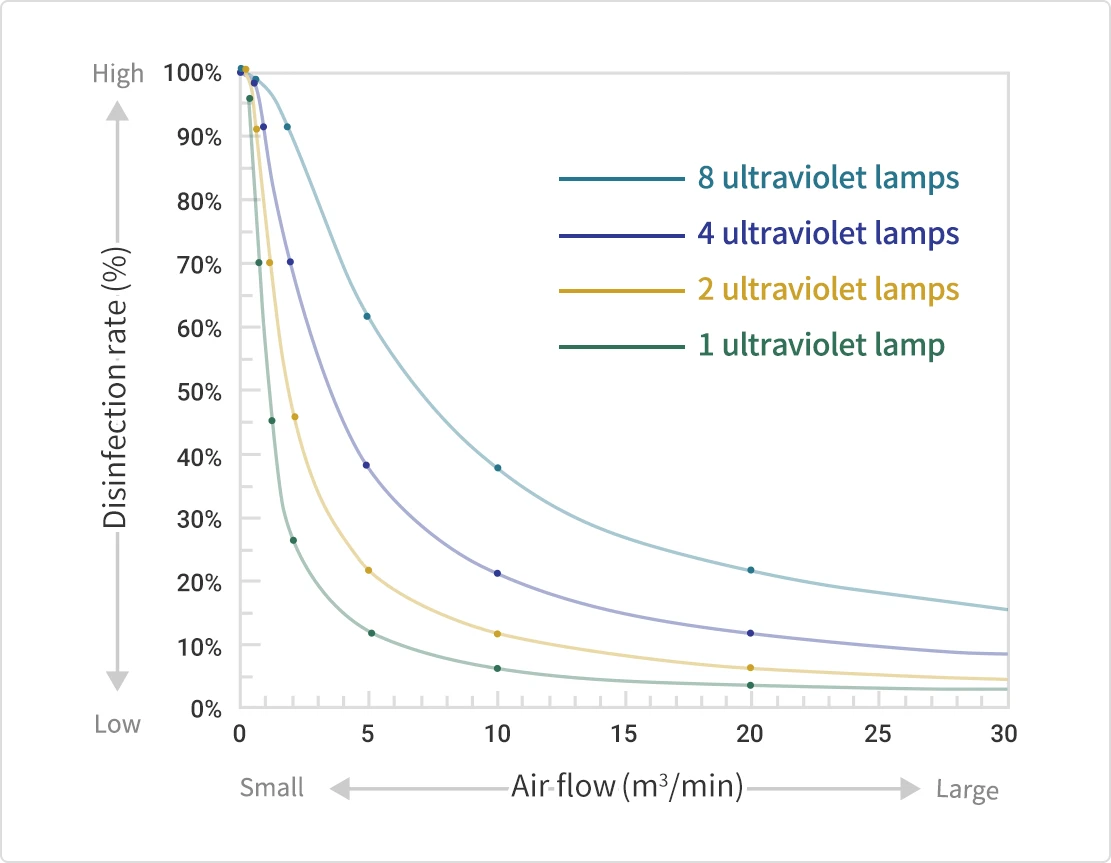

When disinfecting air in a single-pass, the less air flows, the more in disinfection rate, and more ultraviolet light sources, more in the disinfection rate [See Fig. 4] The measurement result of the circulation type air disinfection effect in relation to the basic performance of this single-pass type is shown.

Fig.4: Air Disinfection Rate by Number of Single-pass Type Lamps

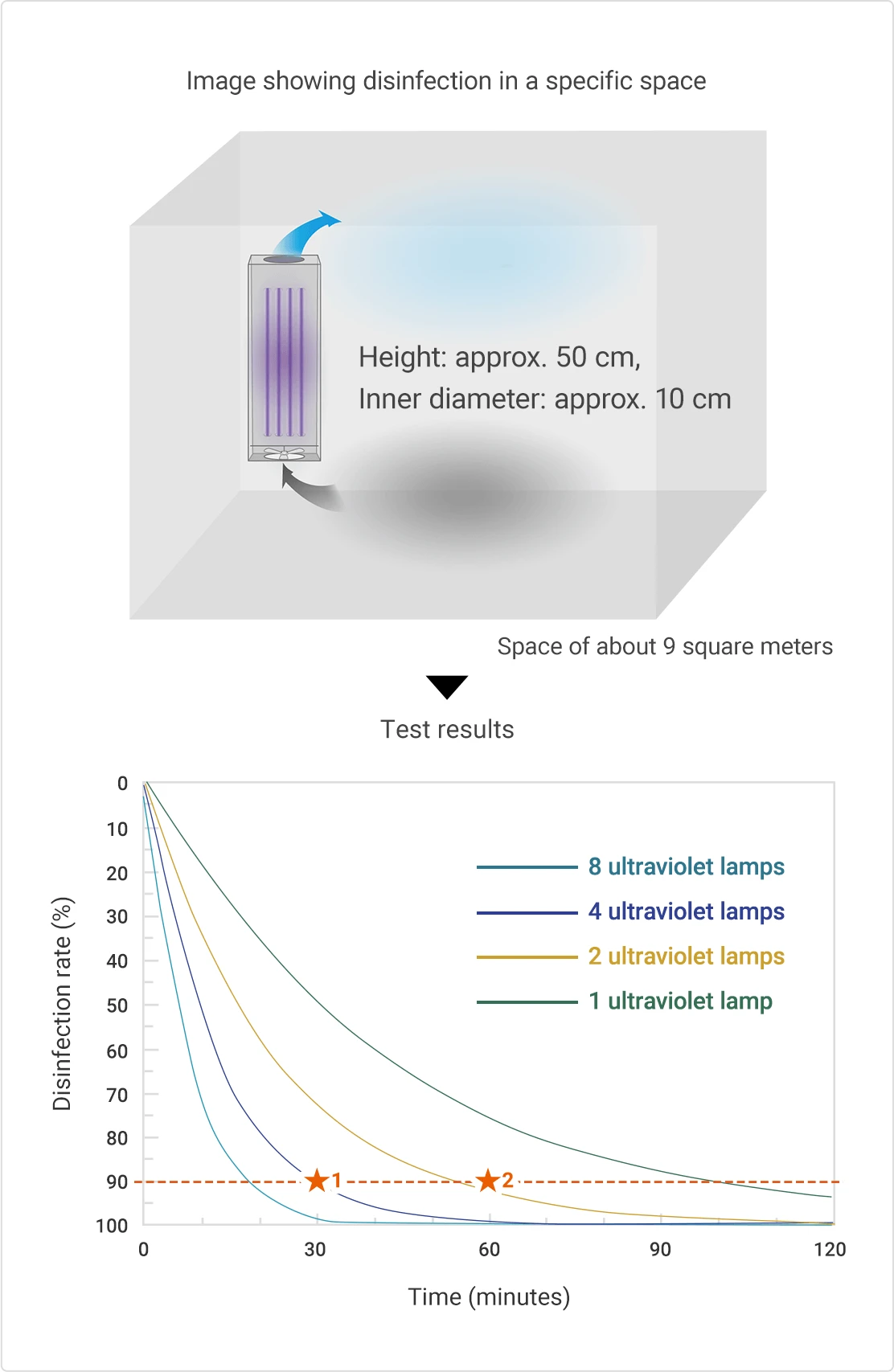

Fig.5 shows the results of the disinfection rate and time by the number of lamps, when a circulation type air disinfection system equipped with UV-CCL was installed in a specific space. To obtain a disinfection rate of 90% after 30 minutes, four or more ultraviolet lamps are required in the system (★1). And to obtain a disinfection rate of 90% after 60 minutes, two or more ultraviolet lamps are required in the system (★2).

Fig.5: Air Disinfection Rate by Number of Lamps: Circulation Type

The more air flow we have, the lower the disinfection rate,

and the less air flow we have, the higher the disinfection.

Therefore, Stanley Electric provides proposals to customers

for the most optimal device to use based on the air flow, the size of the space,

and the disinfection rate the customer wants to achieve.