Disinfection effect of wavelength 265nm

The sterilizing effect of our UV-C technology protects people from the risk of bacterial and viral infections.

With the spread of new coronavirus infections, UV disinfection is now a technology that is attracting even more attention,

However, to make effective use of this technology, it is necessary to select and use the appropriate light source.

Here we introduce some important characteristics of UV-LEDs for your consideration.

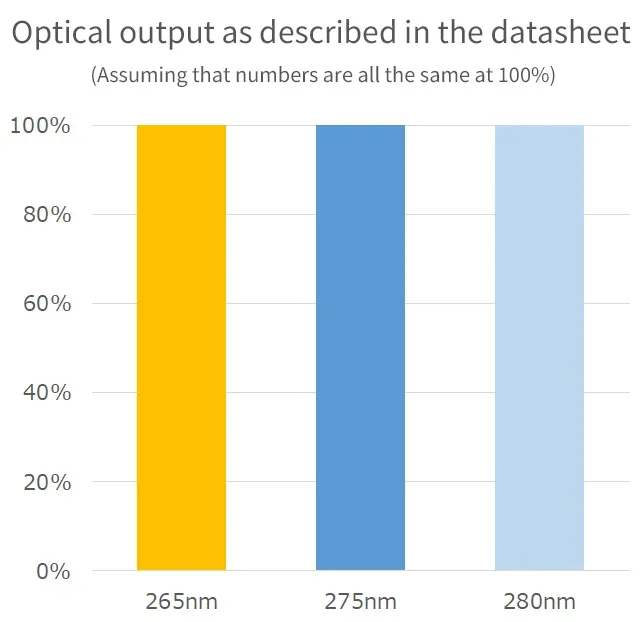

The disinfection power of the LEDs alone is not known from the datasheet.

When considering UV-C LEDs for UV disinfection, it is not possible to determine the disinfection power only from the values listed in the LED data sheet.

With existing LEDs, it is sometimes possible to determine the superiority of specifications based on brightness and light output alone, but the situation is different with UV-C LEDs.

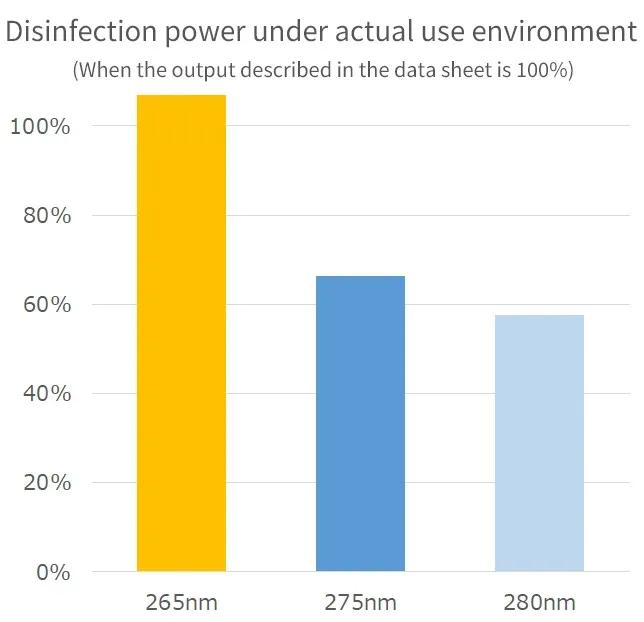

It is especially important to compare the disinfection power under actual use environment conditions.

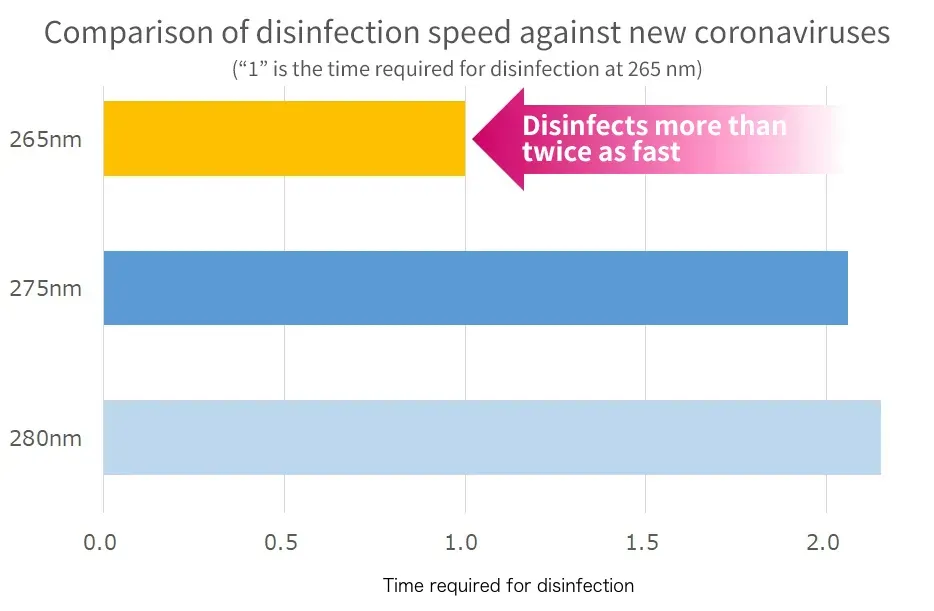

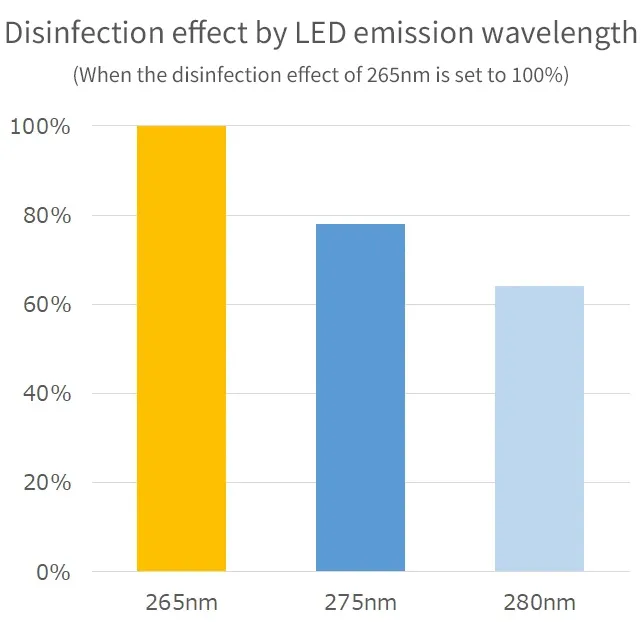

Even though the datasheets show the same light output, 265 nm shows the highest disinfection power.

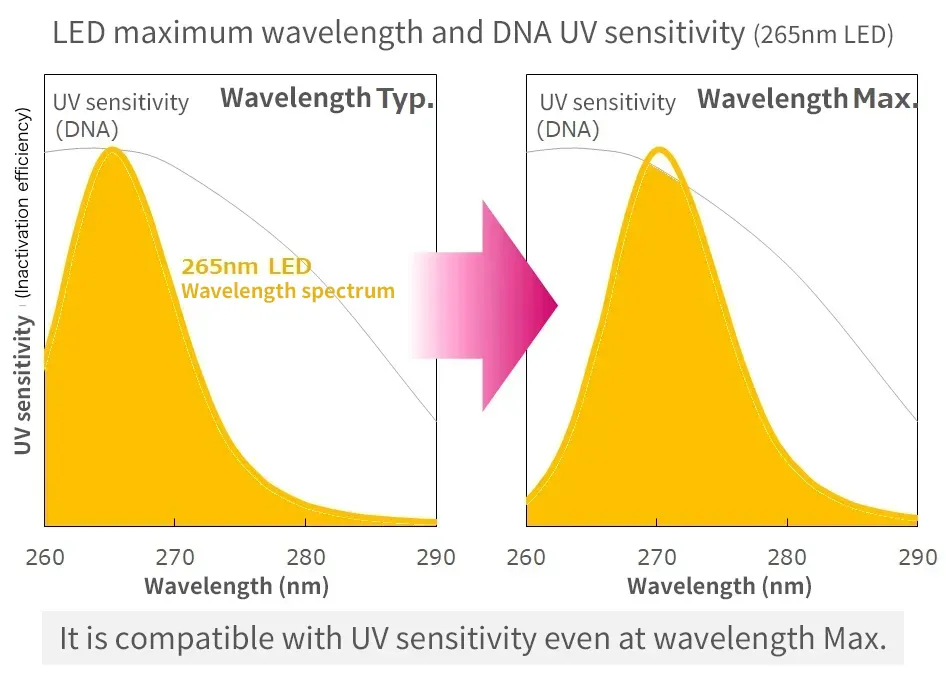

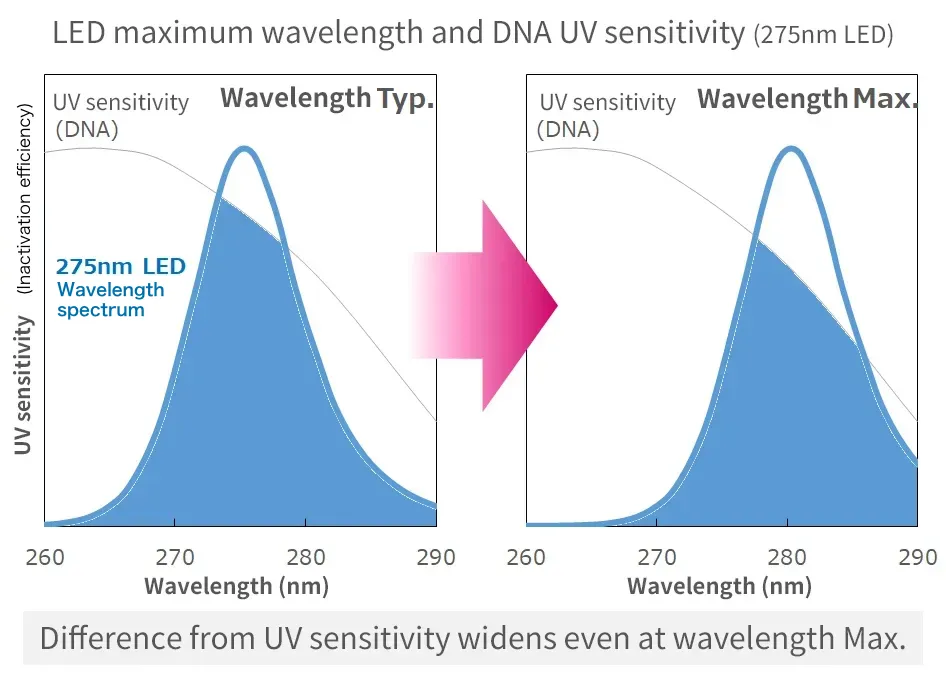

The emission wavelength and temperature characteristics of LEDs are the major factors that affect the disinfection power of deep-ultraviolet LEDs.

We will explain how much these factors affect the disinfection effect.

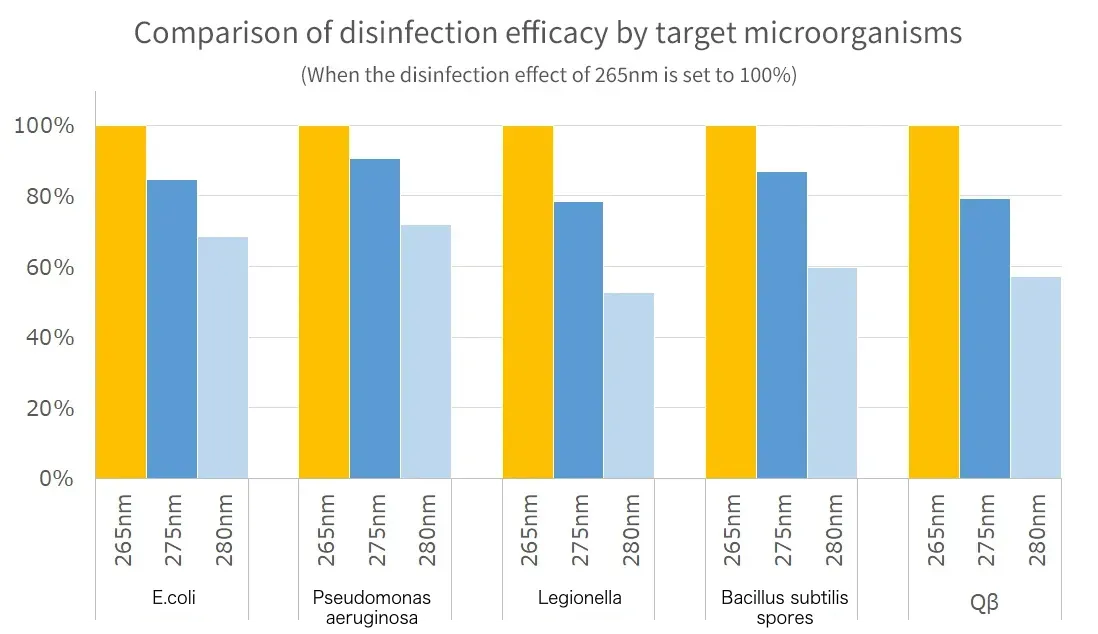

Differences in the disinfection effect due to the emission wavelength.

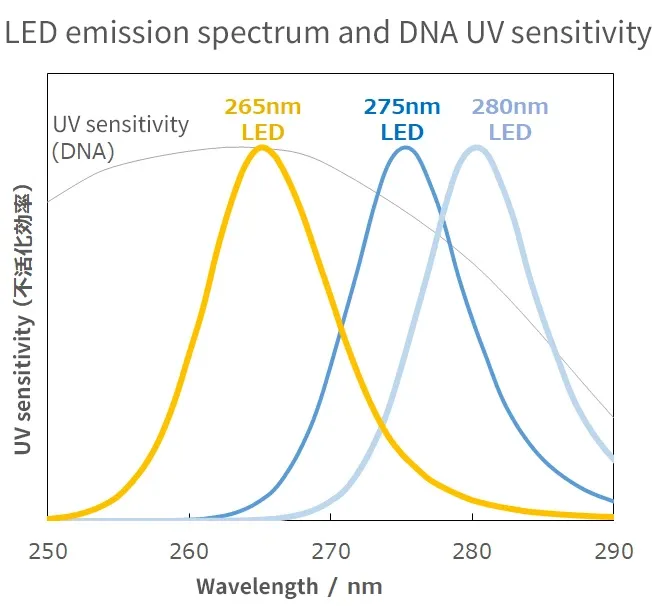

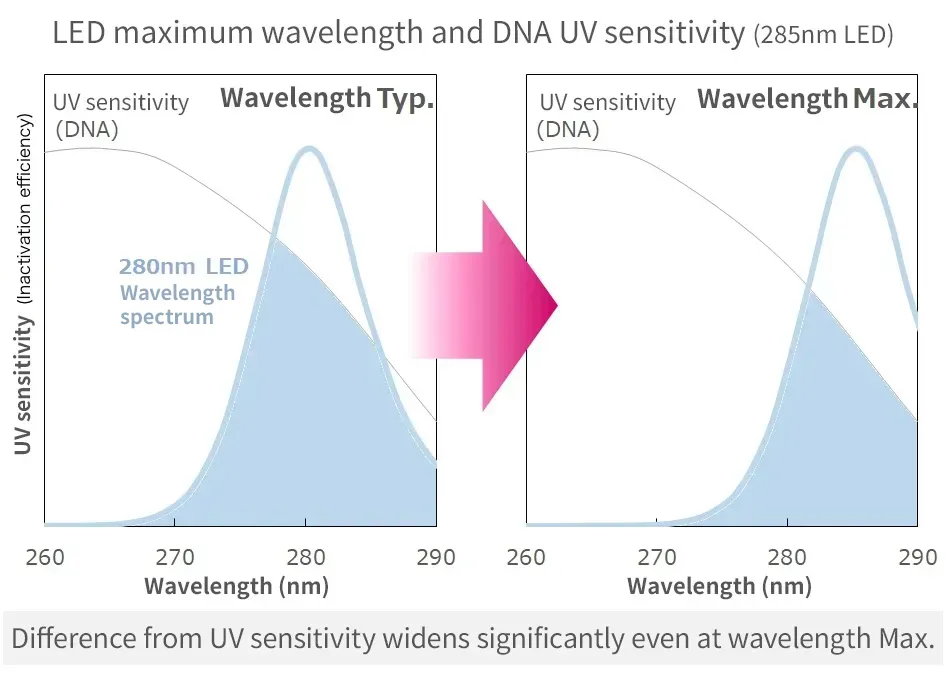

The principle of UV disinfection is the inactivation of micro-organisms by preventing their growth function and taking away their infectivity by attacking their DNA and RNA. DNA, for example, is sensitive to UV light, and sensitivity tends to vary widely with the wavelength of the UV light. Therefore, higher sensitivity to wavelength results in higher disinfection efficacy.

The wavelength with the highest disinfection effect against various microorganisms is 265nm.

The LED wavelength specification also has a minimum/maximum, in which case the disinfection effect will also change.

Care should be taken because changes in wavelength have a direct effect on the disinfection effect.

It is necessary to check whether the wavelength of the UV-C LED to be used is highly effective in disinfection against the target bacteria and viruses.

Changes in LED output and disinfection effect due to heat generated during use

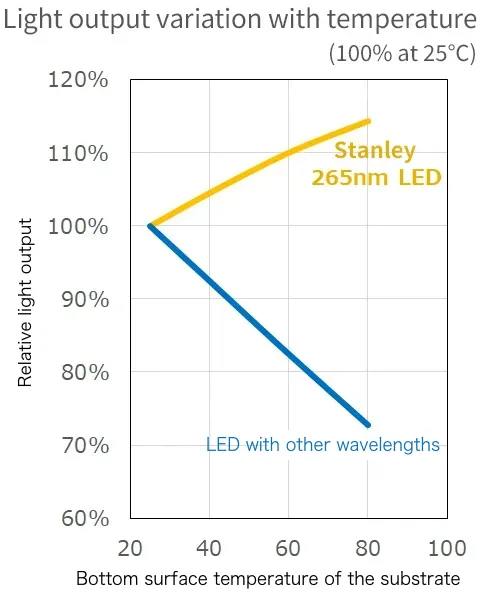

UV-C LEDs are light sources with lower luminous efficiency than existing white LEDs and other light sources. Therefore, the heat generated by the light-emitting elements during use results in a high temperature state.

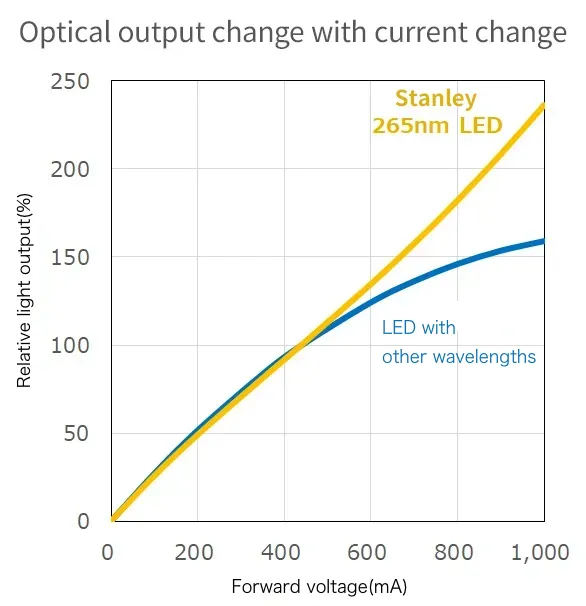

Basically, the higher the current flowing through the LED, the higher the temperature.

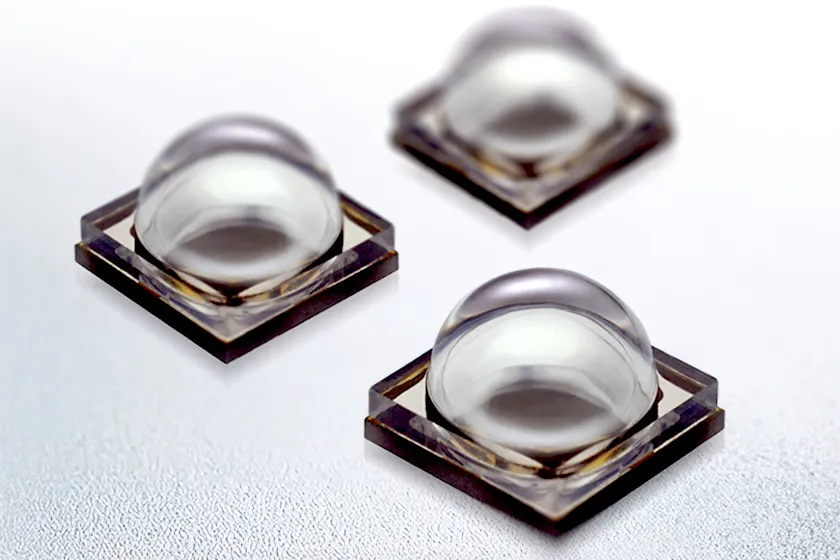

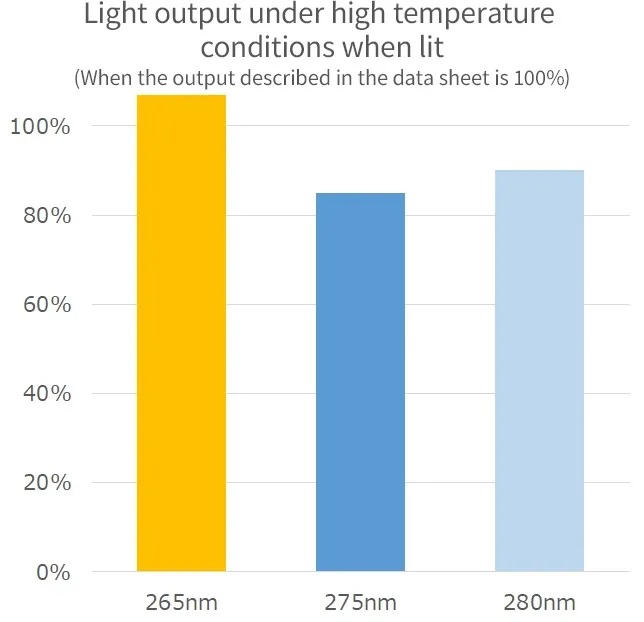

While the light output of general LEDs decreases due to heat generation, our 265nm UV-C LEDs can maintain a high light output.

Our 265nm UV-C LEDs have little decrease in output power due to temperature and current changes.

UV-C LEDs are hot when in use and must be evaluated at the light output of the expected heat generation state.

Click here for UV LED product informationWe also support light source placement, optical simulation, and simple disinfection simulation in UV-C disinfection, so please contact us for more information.