Film-Based Light Distribution Control Technology

Tech Gallery

It is a technology that adjusts the distribution of light to achieve a specific light distribution pattern.

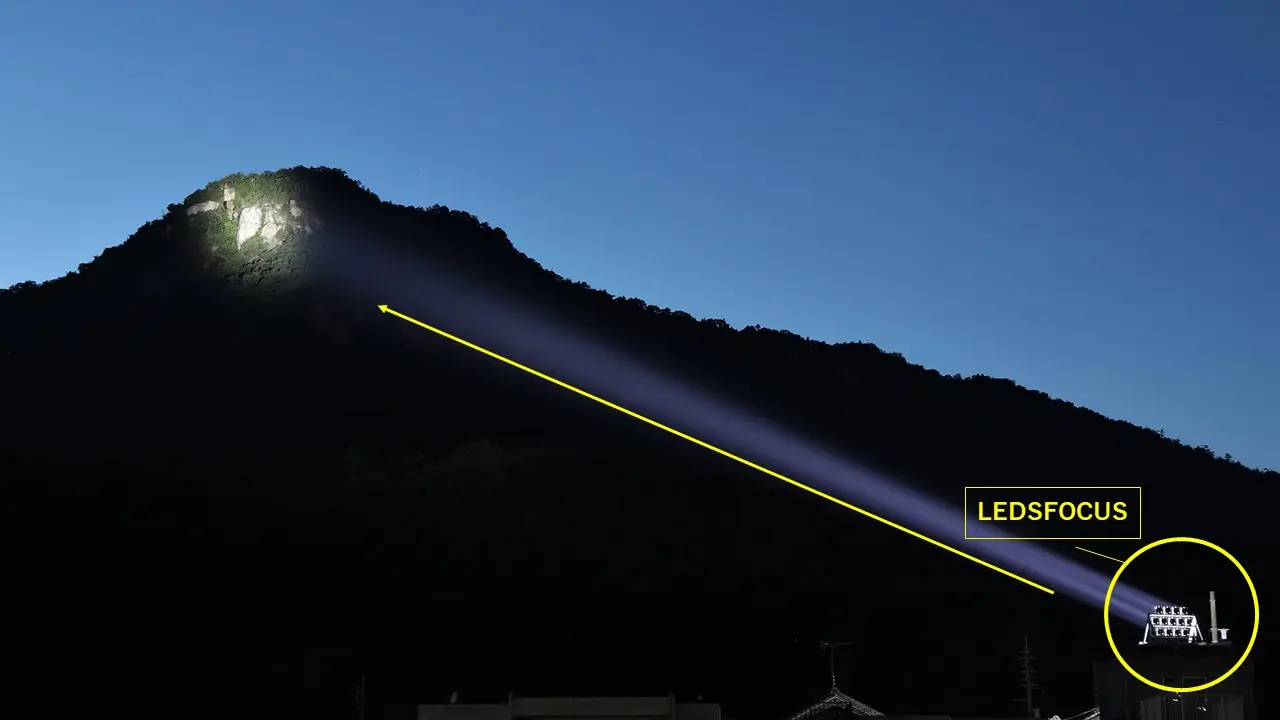

It involves adjusting the way light is emitted using reflectors to achieve the required light intensity, direction, and size.

In our products, it is used in Headlamps and LED floodlights to focus the light, creating a narrow, long beam that shines brightly over long distances.

Basic Structure

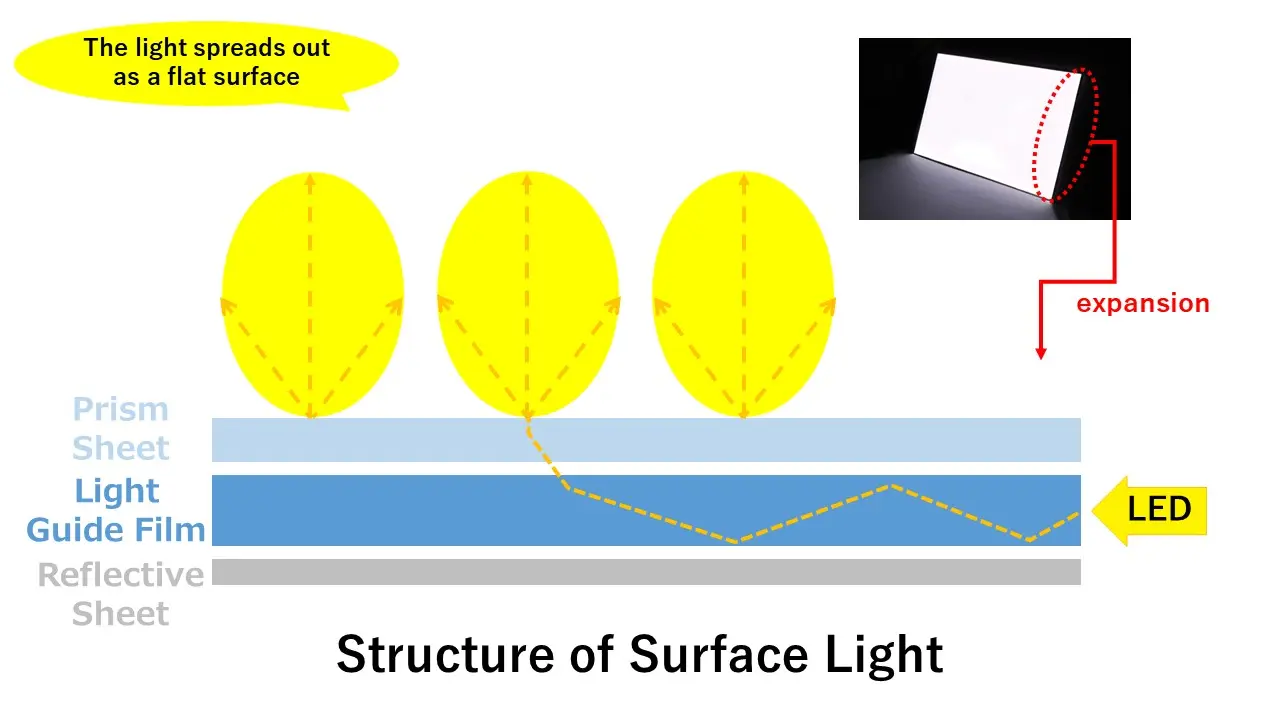

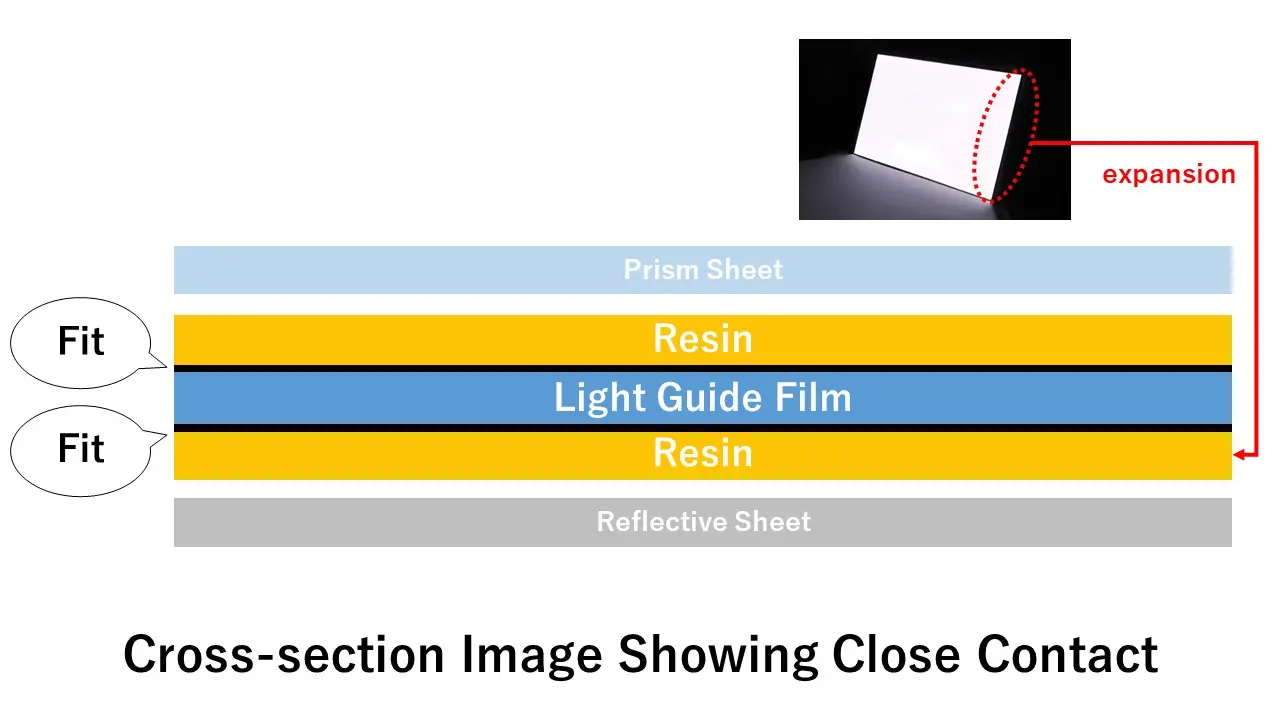

Stanley Electric’s Surface Light Sources Products use a thinner light guide film*1 instead of a light guide plate.

The structure is designed to light up by reflecting light from multiple LEDs illuminating one side within the film and then spreading the light through a prism sheet*2.

*1 Used to convert LED light sources into a surface light source

*2 Utilizes light refraction and reflection to concentrate or disperse light in specific directions

Point 1. Simulation Technology Supporting Light Uniformity/Directionality

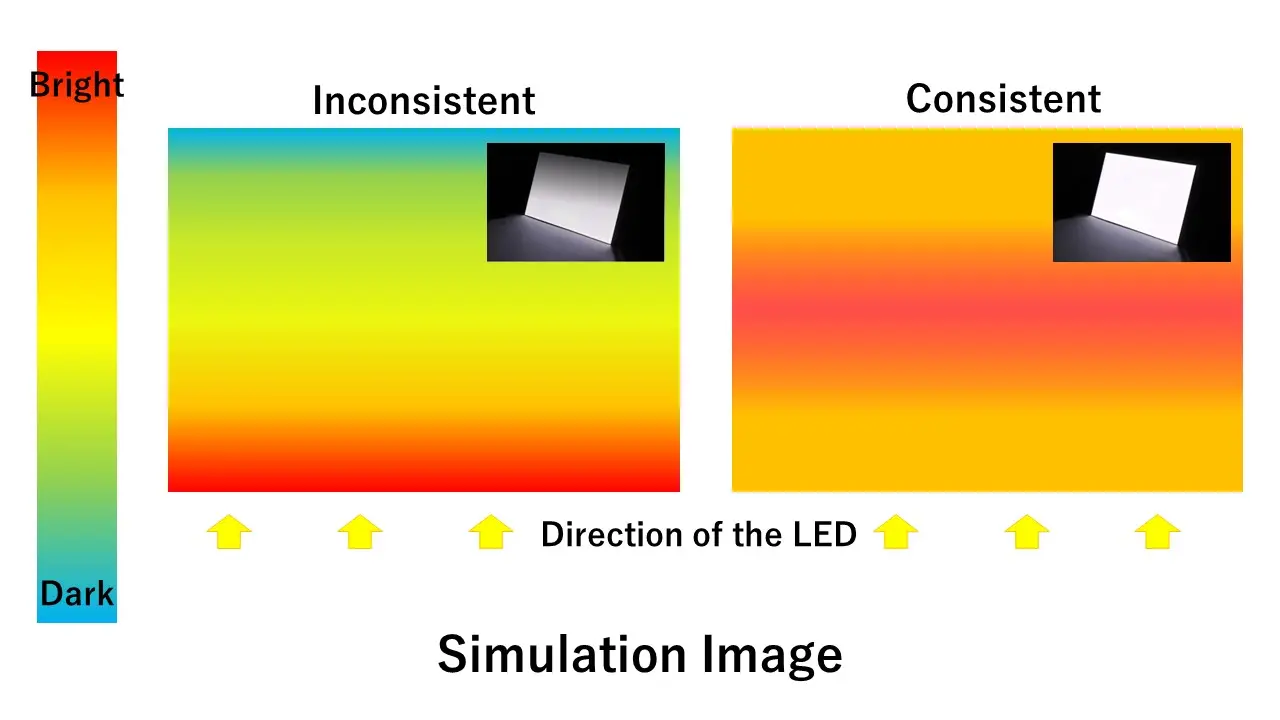

Using simulation software, we achieve uniform brightness across the entire screen size and high luminance by concentrating light in specific directions.

Typically, the side where LEDs are placed becomes brighter while the opposite side remains darker. However, by adjusting the angle at which light reflects, we ensure overall brightness remains uniform.

Furthermore, by concentrating light in a specific direction, we achieve higher brightness with the same power consumption, contributing to energy savings.

Point 2. Technology for Forming Optical Patterns on Thin Films

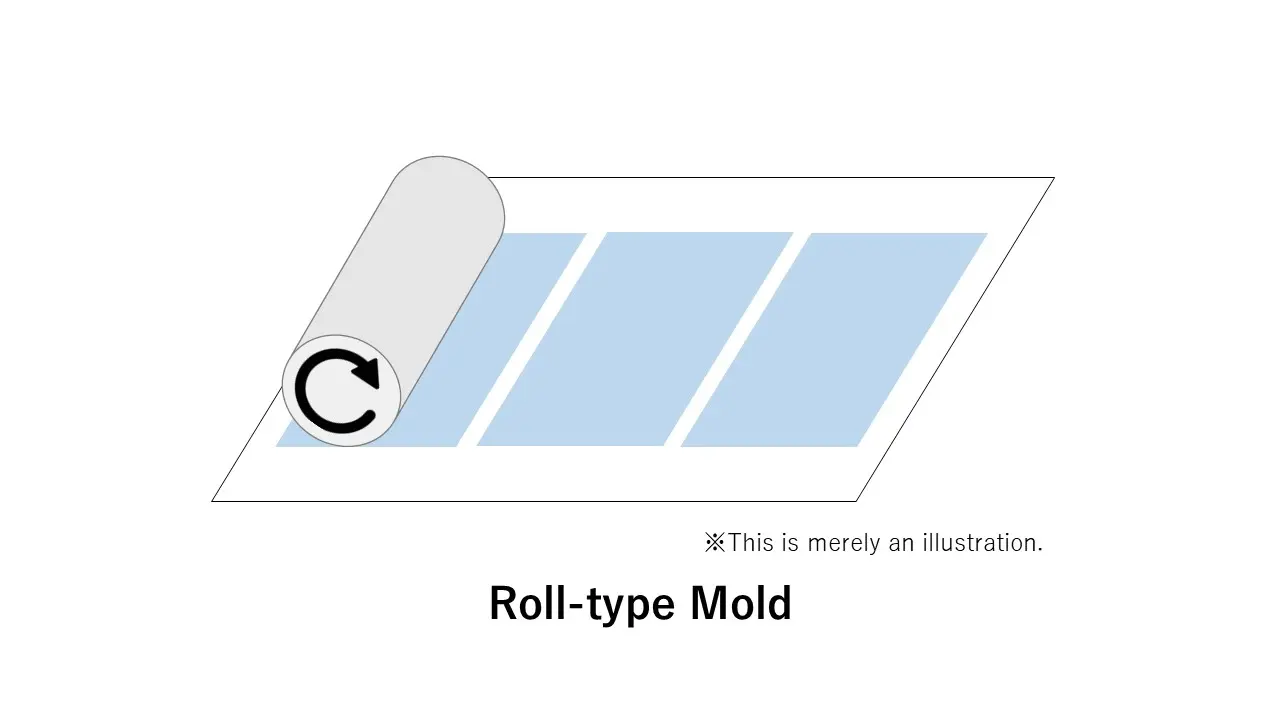

To form the pattern shapes derived from simulations onto the film, we developed a Roll-type mold.

Since injection molding, the method typically used for light guide plates, makes thinning difficult, we use a uniquely developed Roll-type mold.

The Roll-type design also enables continuous forming, contributing to greater efficiency.

Point 3.Technology Enabling High-Quality Mass Production

We achieve high adhesion between materials of different types: film and resin.

To achieve high adhesion and high purity bonding while maintaining the fineness of the pattern, careful selection of materials and precise control of manufacturing conditions are essential. This presents a highly challenging process.

To achieve stable mass production while maintaining optimal values, we have established a production system combining strict inspection standards with management techniques cultivated through our extensive experience.

Currently, we offer 2 types of products for notebook PC and tablet LCD displays.

CBL, optimized for high brightness from the front and low power consumption.

CBL-TCO, new product, which expands the viewing angle* while balancing versatility and low power consumption

*Viewing angle: The angle or range within which colors and displayed content appear correctly, similar to when viewed head-on.

Future applications are envisioned for environments with thickness/height constraints, targeting uses that require efficient light utilization.