High-reflectivity Coating Technology for Ultimate Light-reflecting Efficiency

Tech Gallery

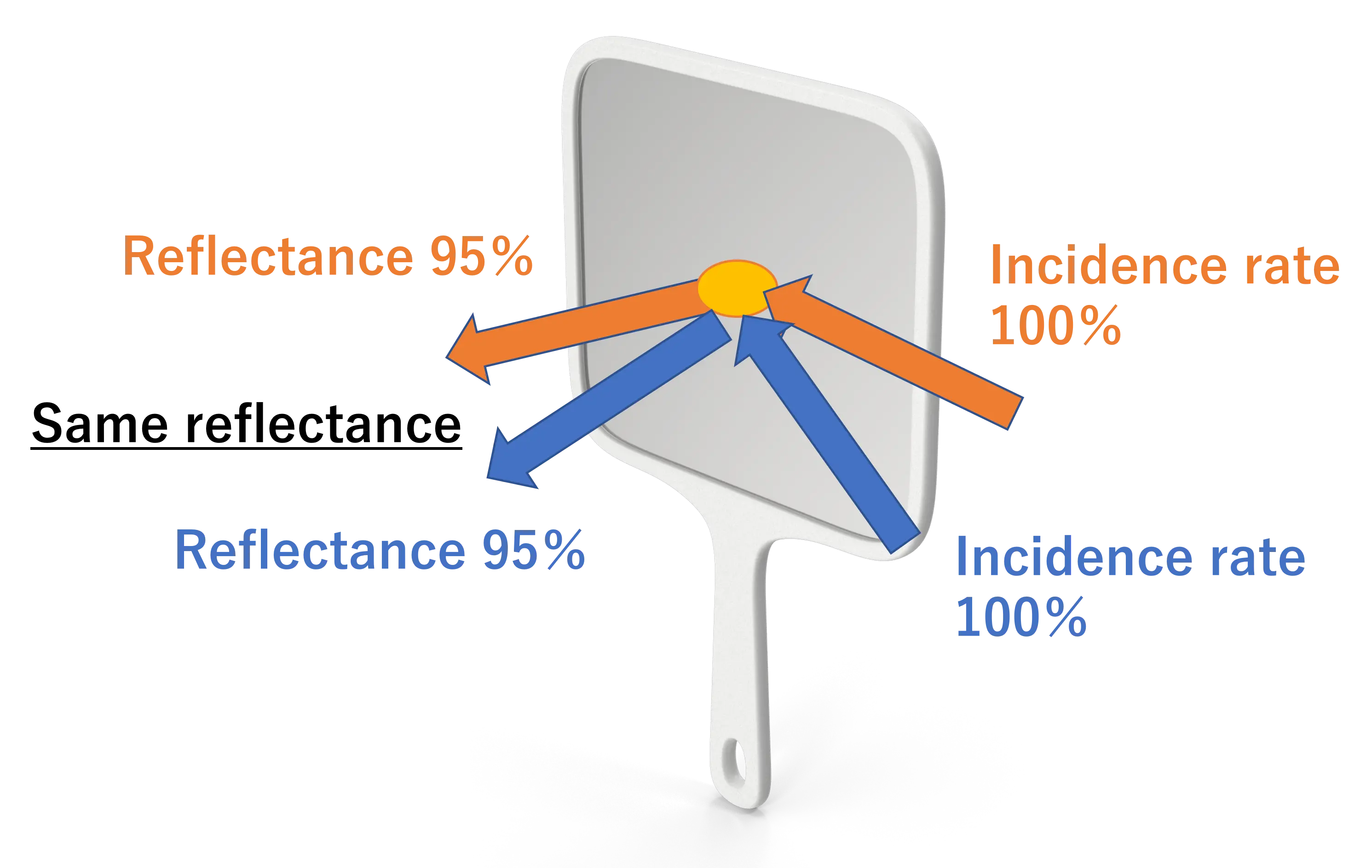

Normally, mirror surfaces provide varying levels of reflectance depending on the angle of incoming light, but by applying high-reflectivity coating to the mirror surface, it is possible to uniformly reflect a specific type of light regardless of the angle. Furthermore, by carefully designing the membrane composition, it is also possible to improve the reflectivity itself.

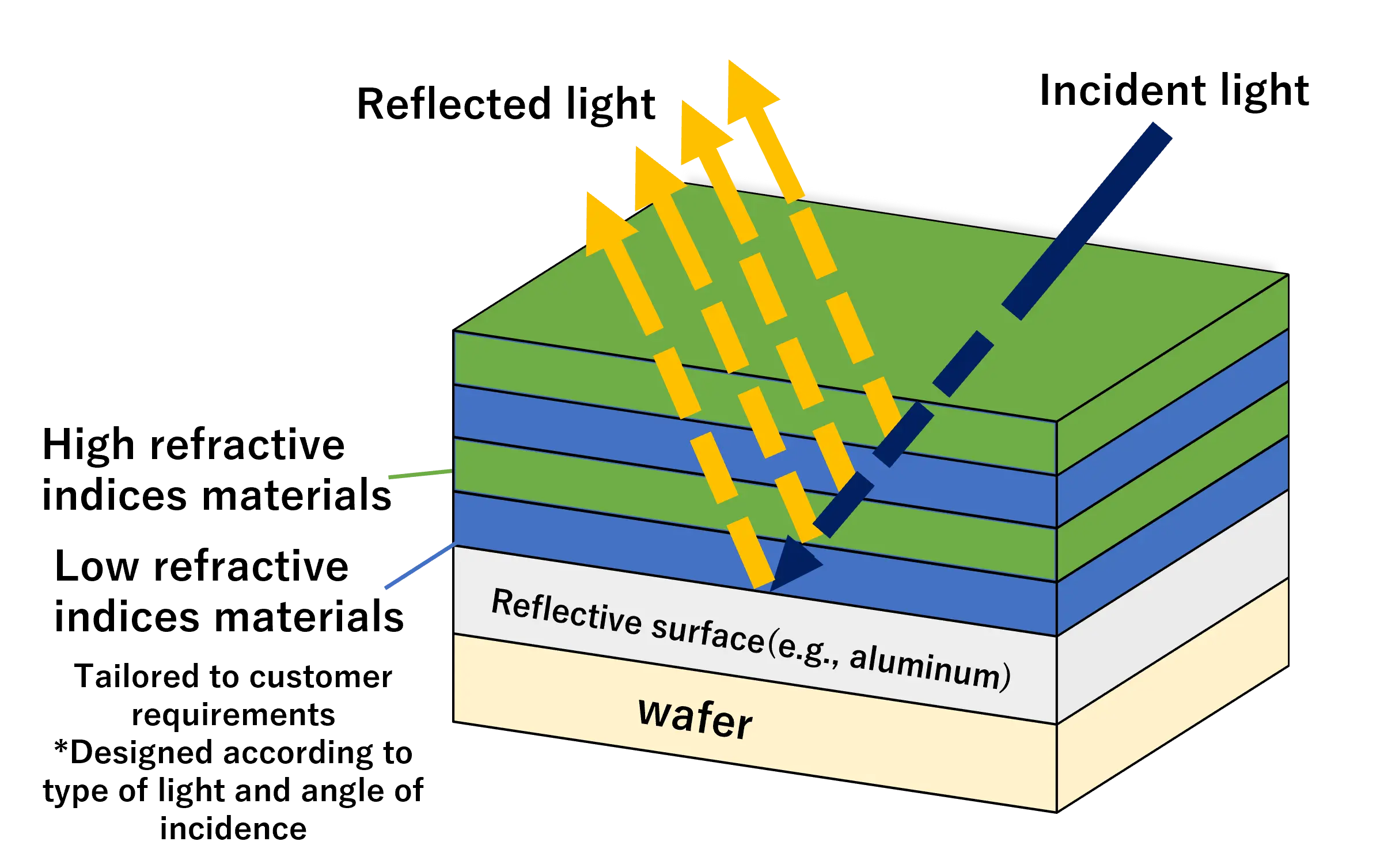

As shown in the figure on the left, high-reflectivity coating consists of alternating layers of materials with different light-passing properties (i.e., those with high and low refractive indices). This enables more light to be reflected with greater efficiency. (Essentially, light is intensified as the phases of the reflected light in each layer are aligned.)

Originally, this coating was used on the surface of optical elements, but we are applying it on semiconductor substrate wafers to efficiently control light. The coating is carefully formed to improve adhesion to the wafer as well as to provide a coating structure suitable for subsequent semiconductor processes.

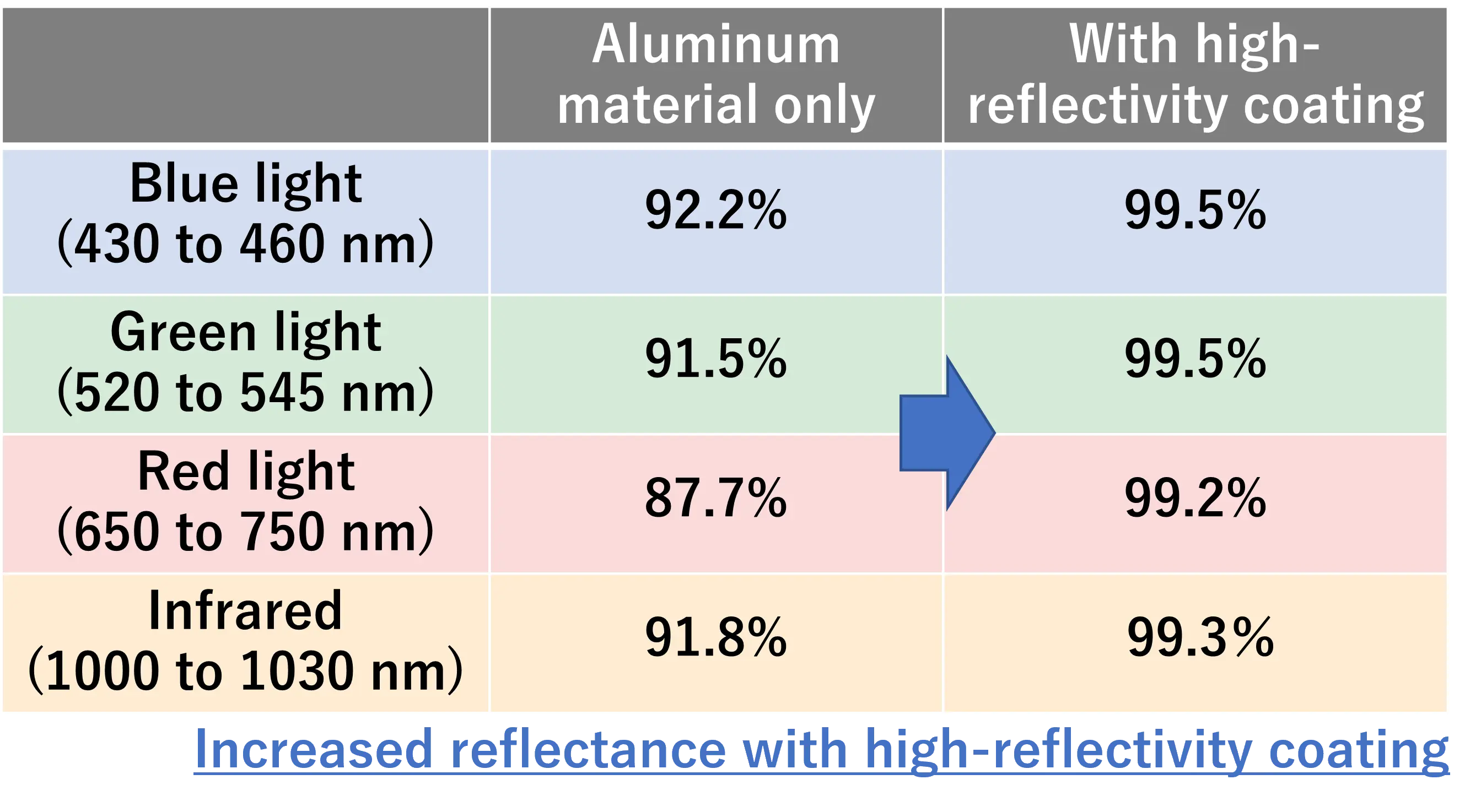

1. Coating that achieves the desired reflectance

The composition and materials of the high-reflectivity coating are adjusted according to the type of light used and the angle from which the light enters.

It improves reflectivity significantly compared to reflective surfaces made of aluminum material only.

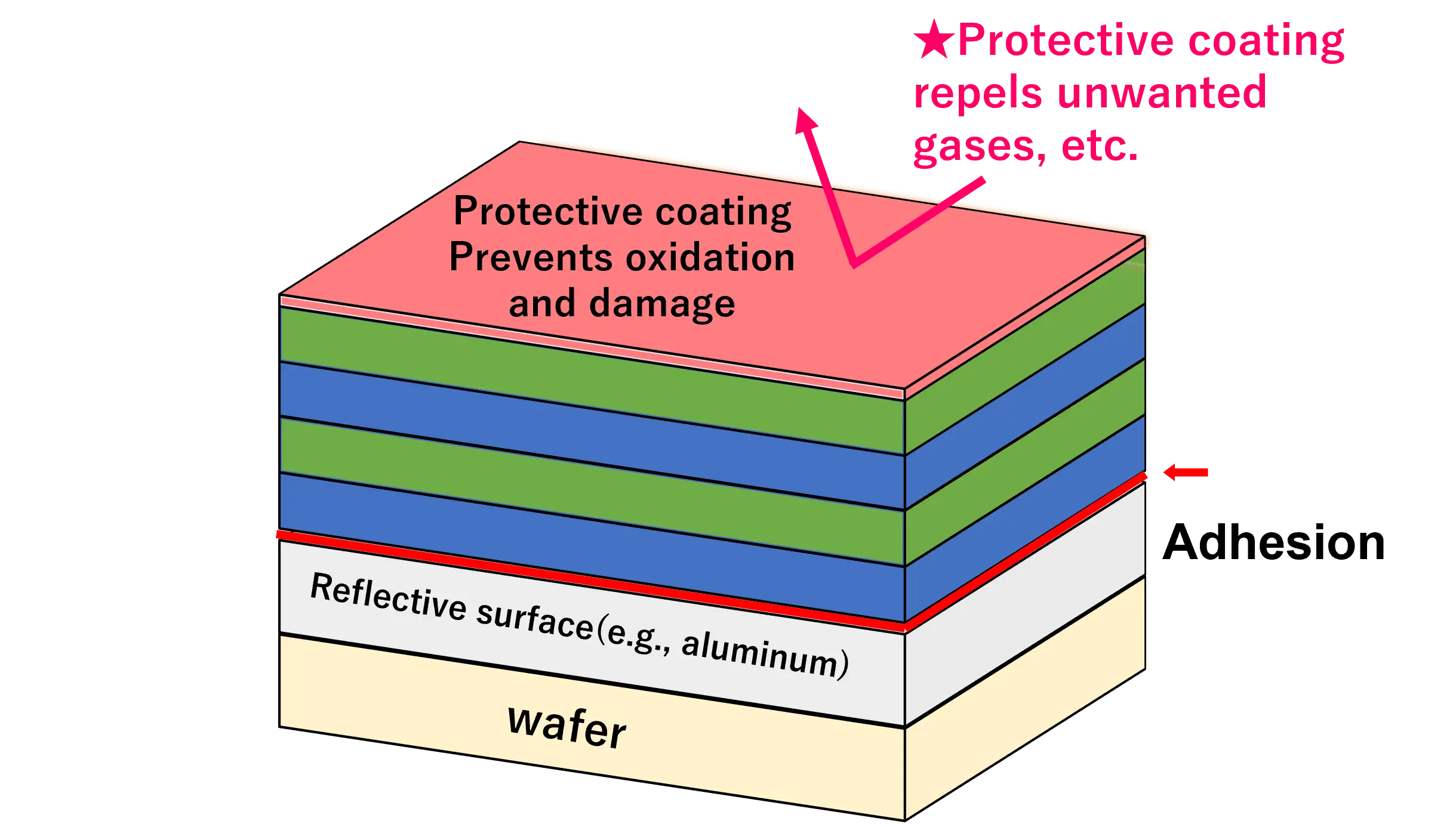

2.Highly durable and reflective coating

The aluminum alloy reflector surface, serving as the foundation, enhances adhesion with the high-reflectivity coating, providing a stable base.In addition, the protective coating on the top layer prevents oxidation and damage and suppresses any degradation in reflective performance. This protective coating also boasts excellent mechanical strength, making it a highly durable coating.This results in a coating that offers excellent durability, long life, and high reflectivity.