Piezoelectric Film Formation Technology

Tech Gallery

“ Your product won’t operate under high temperatures. ”

Our unique piezoelectric film enables components to be stably operated for long periods of time even under harsh temperatures of 125°C. For example, components inside vehicles are often exposed to the heat of the sun, so they must be heat resistant to ensure high-temperature operation.

1. Film formation technology for extended operation under high temperatures

Stanley Electric uses its proprietary technology to form piezoelectric film capable of stable operation under high temperatures.

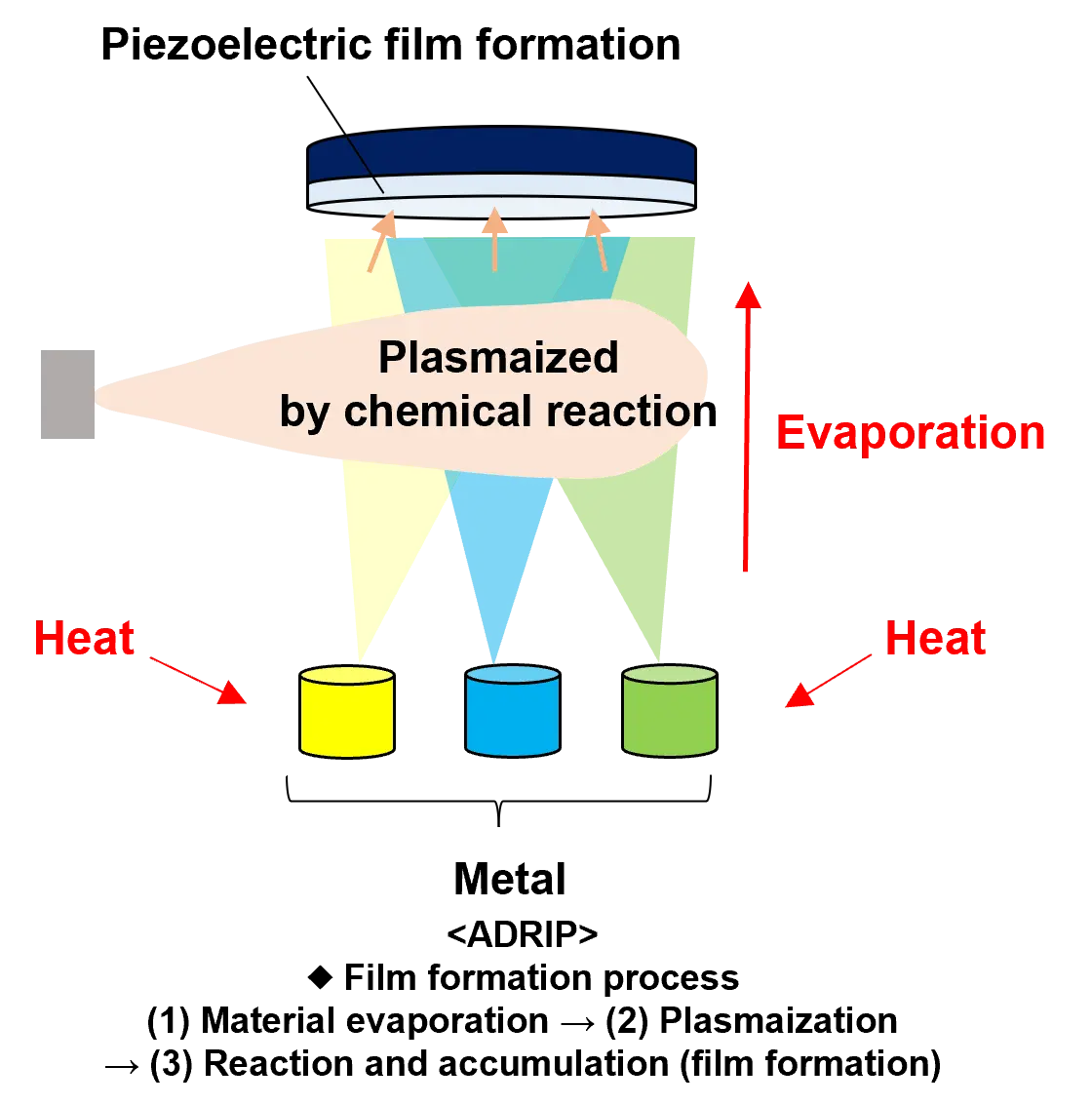

ADRIP (Arc Discharged Relative Ion-Plating) is an advanced film formation technology that plasmaizes materials such as metals to form PZT (lead zirconate titanate) film with a uniform thickness.

Under optimal process conditions, PZT produces highly reliable piezoelectric film at the desired functionality and performance. It can maintain its functionality even at temperatures about three times higher than other piezoelectric film materials, such as BaTiO₃ (barium titanate).

2. Film formation technology for high output

ADRIP can also be used to form thicker film.

A thicker film increases the force of expansion and shrinkage when voltage is applied, which enhances the output power for driving small machines. This also enables more powerful and stable operation, contributing to improved product performance.