Bonding Technology Using Metallic

Tech Gallery

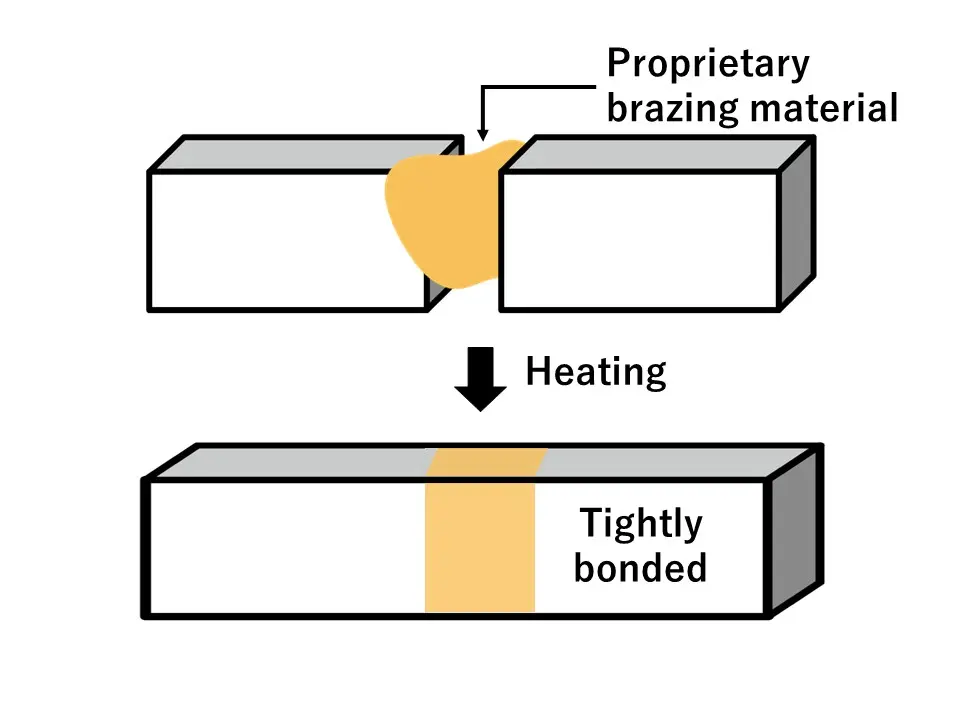

1.High strength bonding

Our proprietary brazing material firmly bonds metals together to achieve a bonding strength that is nearly twice as strong as that of soldering. It remains stable even under severe conditions such as high temperatures and vibration. As a result, it is no longer necessary to worry about joint strength over long periods of use.

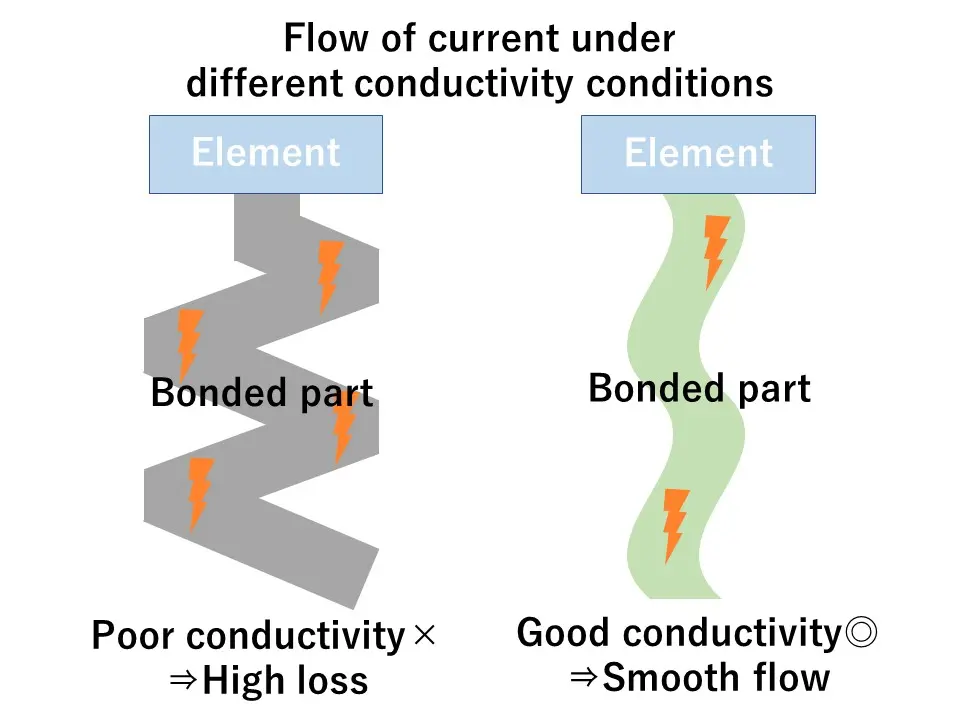

2.Excellent electrical and thermal conductivity

Its high conductivity allows heat to escape efficiently and prevents thermal deterioration and performance degradation of components. It is also suitable for high-power components and designs where heat concentration is a concern, as well as applications where heat generation measures are required.

Conventionally, soldering has been widely used to join metal surfaces together.

It is a highly popular technique because it offers a good balance in terms of workability, cost, and performance.

In recent years, however, a better technique has been required to accommodate the increasing demand for high-performance products that operate under severe conditions.

In response, bonding techniques that use metallic bonds have been attracting attention because of their superior bonding strength, thermal and electrical conductivity, and high reliability in applications that require automotive-level quality.