Stanley Electric Launches "ASTUV", Industry-First Coating Technology Brand

- Leveraging light technology to reduce energy consumption in coating processes -

Corporate

0

To News

Stanley Electric Co., Ltd. (Head Office: 2-9-13 Nakameguro, Meguro-ku, Tokyo; President and CEO: Yasuaki Kaizumi) is pleased to announce the launch of its new coating technology brand, “ASTUV”, developed with the aim of reducing CO₂ emissions.

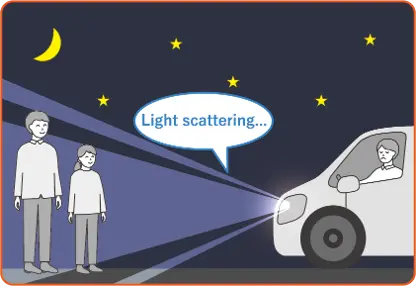

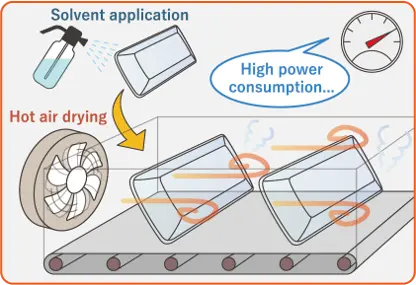

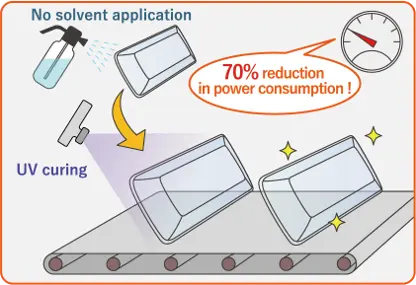

This industry-first innovation combines a newly developed UV-curable coating material with a manufacturing process that uses UV light instead of hot air for drying curing. By replacing conventional processes in the production of our automotive headlamps with ASTUV, energy consumption can be reduced by more than 70%* compared to our current levels.

* Based on FY2024 data, including coating processes such as anti-fog and hard coating.

This industry-first innovation combines a newly developed UV-curable coating material with a manufacturing process that uses UV light instead of hot air for drying curing. By replacing conventional processes in the production of our automotive headlamps with ASTUV, energy consumption can be reduced by more than 70%* compared to our current levels.

* Based on FY2024 data, including coating processes such as anti-fog and hard coating.

The automotive industry is under increasing pressure to work toward carbon neutrality. In response, Stanley Electric Group has set a target to reduce CO₂ emissions from business activities by 50% by 2030 (compared to FY2019). One key focus is reducing thermal energy usage at our global manufacturing sites through production process innovation.

ASTUV combines

- A newly developed solvent-free, surfactant-free UV-curable coating material.

- Stanley’s proprietary UV irradiation technology, optimized in terms of intensity, distance, and exposure time.

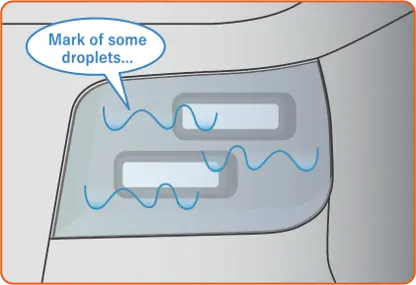

This eliminates the need for energy-intensive hot air drying in headlamp coating processes, reducing CO₂ emissions while enhancing product quality.

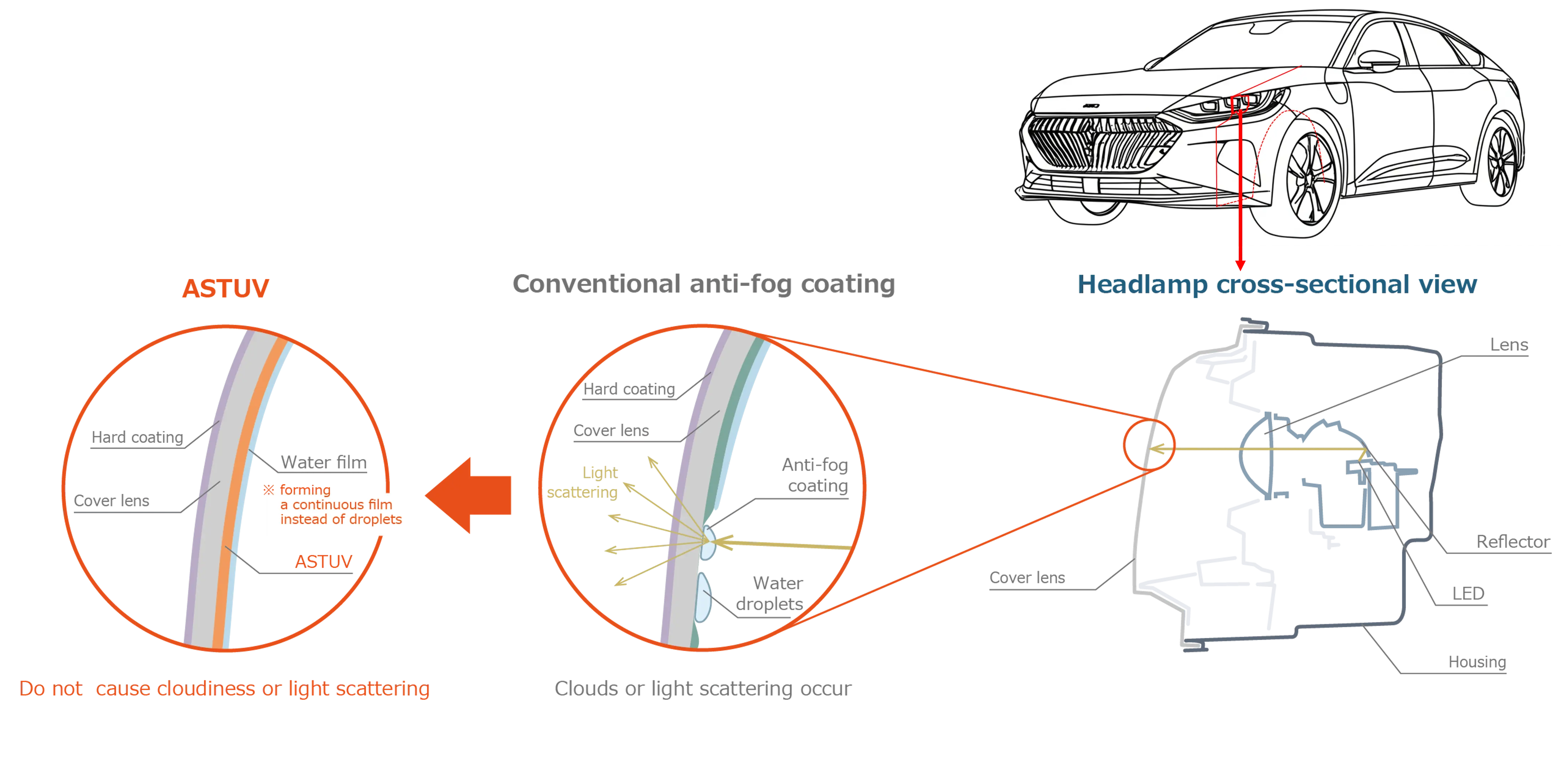

We plan to introduce a series of innovations in phases - starting with anti-fog technology, followed by hard coating technology, and finally decorative technologies for design components - to further expand the application scope of ASTUV.

- A newly developed solvent-free, surfactant-free UV-curable coating material.

- Stanley’s proprietary UV irradiation technology, optimized in terms of intensity, distance, and exposure time.

This eliminates the need for energy-intensive hot air drying in headlamp coating processes, reducing CO₂ emissions while enhancing product quality.

We plan to introduce a series of innovations in phases - starting with anti-fog technology, followed by hard coating technology, and finally decorative technologies for design components - to further expand the application scope of ASTUV.

We have already begun proposing this technology to automobile manufacturers, and aim to replace the surface treatment process for our automotive lamps with ASTUV at all our locations by 2030. Furthermore, we will continue to advance ASTUV technology and promote power reduction not only in the surface treatment process of automotive lamps but also across other manufacturing processes. Through these efforts, we contribute to reducing CO₂ emissions within the automotive industry supply chain.