Supply Chain Management

Basic Approach to Corporate Governance

The Group partners with suppliers on equal and fair relationships and is engaged in sincere transactions in compliance with relevant laws, regulations, and agreements. Specifically, we welcome both domestic and foreign partners with equal opportunities for transactions and select suppliers in accordance with fair and rational standards based on such items as quality, price, delivery, safety, and the environment. We also strive for mutual prosperity through transactions and under trust and cooperation, making efforts to maintain and strengthen long-term growth and competitive edge.

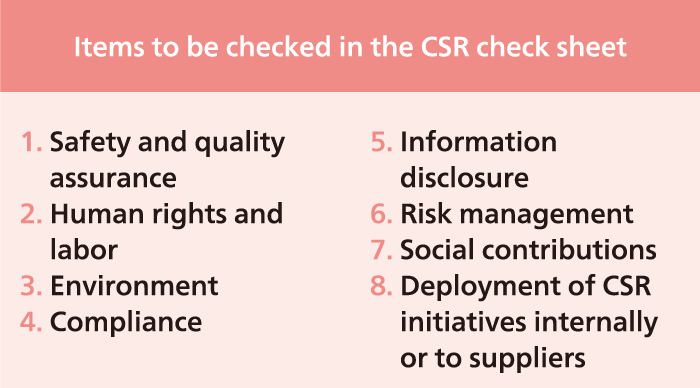

Identifying the Current Status Using the CSR Check Sheet

Every year, we distribute the CSR check sheets to suppliers and ask them to examine their own activities as part of strengthening CSR in the supply chain. In FY2024, we distributed the sheets to more than approximately 1,300 suppliers globally, collected the results of their investigations, and confirmed that there were no problems in terms of respect for human rights, working conditions, working environment, etc. In addition, the examination results revealed that they had common issues such as “deployment of CSR initiatives to suppliers, which are our sub-suppliers” and “promotion of in-house education.” We will continue to work to solve these issues in cooperation with our suppliers.

Confronting the Problem of Conflict Minerals

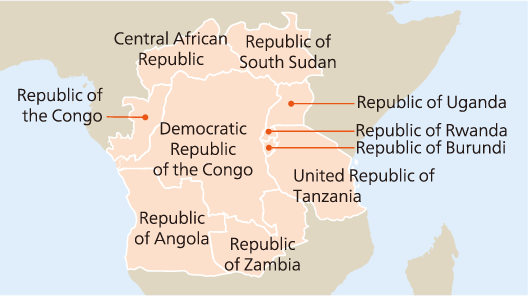

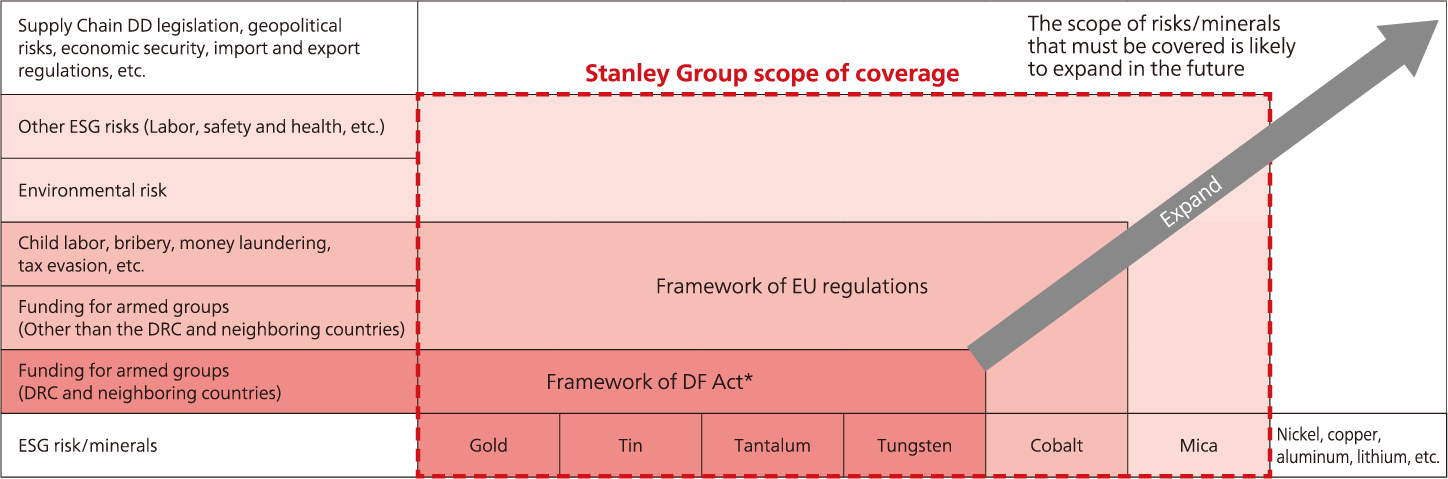

We are deeply concerned about the problems of human rights abuses and environmental damage by armed groups in the Democratic Republic of the Congo (DRC) and neighboring countries as well as the countries included in the latest CAHRAs list*1published by the EU under the EU Conflict Minerals Regulation. Because these groups appear to be financed by dealings in conflict minerals*2, we are taking measures to ensure supply chain transparency so as to avoid abetting these problems and are promoting responsible procurement of minerals. In addition, to respond to the survey target list items in the recently accelerating “responsible minerals procurement” and related laws and regulations, the Group conducted surveys which included copper, lithium, graphite, and nickel in addition to 3TG*3, cobalt, and mica, starting from FY2025.

- 236 regions in 28 countries as of March 2025

- Gold, tin, tantalum, tungsten, and other minerals extracted in the Republic of Congo and neighboring countries (minerals determined by the U.S. Department of State to be a source of funds)

- Tin, Tantalum, Tungsten, Gold

Scope of coverage for our company based on “Responsible Mineral Procurement”

Excerpt from JEITA Responsible Minerals Procurement Briefing 2025 (P27)

|

- Dodd-Frank Act. Stipulated under Article 1502 (Conflict Minerals Provisions) of the US Financial Regulatory Reform Act

Initiatives for Stable Procurement

To maintain and strengthen a stable and uninterrupted procurement system, we ensure that all suppliers who provide parts use the Group’s “fire and disaster prevention and response check sheet” to inspect their own measures, reflect the results in their own fire and disaster prevention and response activities, and strengthen their quality and structure. We also ask secondary suppliers, their suppliers, and sub-suppliers to carry out these activities in the same way. In FY2024, we asked about 100 suppliers in Japan to submit the results of inspection of their own measures to check their current status, and we provided information and advice for their further improvement.

As for raw materials procurement, we avoid risks by having multiple sources (diversification of suppliers), which we have been working on. In response to the continuous hike in resin raw material prices since 2021, we are working on cost reduction through selection and concentration while maintaining the diversification of raw material procurement sources.

Initiatives for the Environment and Enhancing the Quality of Purchased Goods

As a manufacturer of important safety components, we regularly work together with our suppliers to improve quality under the motto, “Don’t buy, make, or pass on defects,” and hold a purchasing policy briefing, and other briefings at various locations to assist them in strengthening quality control.

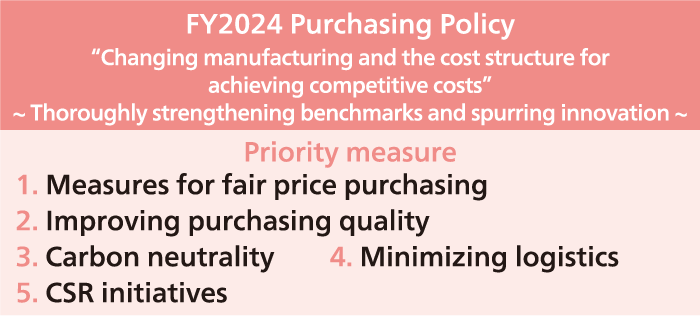

At the FY2025 Purchasing Policy Briefing, four priority measures were outlined under the topic of “Transforming the manufacturing and cost structure to achieve competitive costs and expand the business.”

In addition, based on our Green Procurement Guidelines, we ask suppliers to maintain and improve their environmental management systems (EMS) and to manage and reduce the use and emission of environmental concern substances. We regularly conduct supplier surveys on the environment and enter transactions with companies that are registered as “eco partners.”