Decarbonization and Circular Economy

Realizing a Decarbonized Society

Metrics and Targets

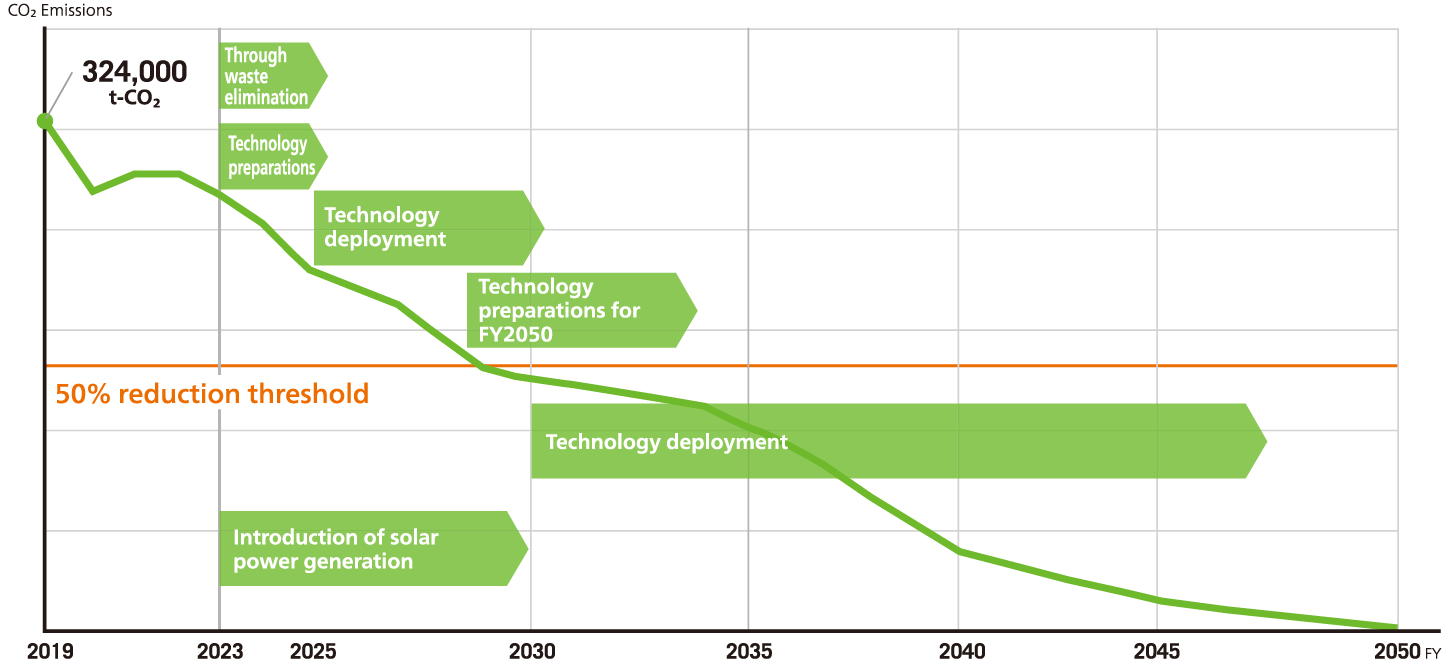

We set the target for FY2021 of “Reducing CO2 emissions from our business activities by 50% by FY2030 compared with FY2019 and achieving carbon neutrality by FY2050.”

The result for FY2024* was a reduction of 24% compared with the 380,000 t-CO2 for the base year of FY2019. We have already developed a road map for reduction by FY2050 and are now working on its implementation.

* Recalculated results for the past fiscal year following the acquisition of Thai Stanley Electric Public Co., Ltd. (THS), as a consolidated subsidiary in FY2024

Targets related to climate change (base FY2019)

| Metric | Target | |

|---|---|---|

| Scope1,2 Amount of CO₂ emissions from our business activities | FY2030 50% reduction | FY2050 Achieve carbon neutrality |

Roadmap for reducing the amount of CO₂ emissions from our business activities (Scope1, Scope2)

<Basic approach of reducing CO2 emissions>

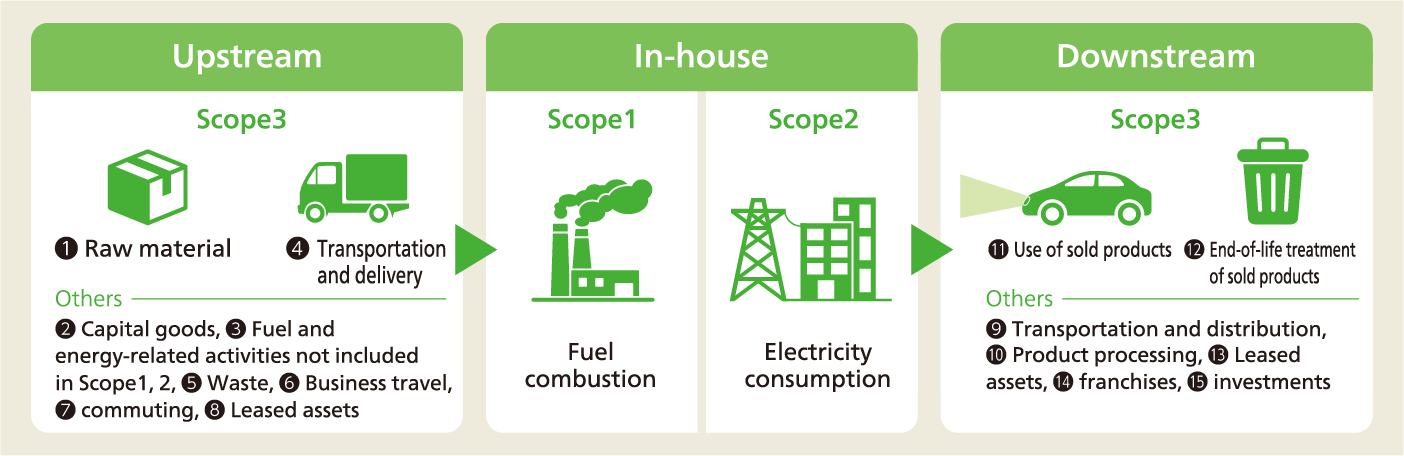

We are focusing on reducing CO₂ emissions at our production sites, which account for more than 90% of the Group’s CO₂ emissions. One measure in particular that we are focusing on is to improve manufacturing for reducing manufacturing that uses heat. With this, we are aiming to achieve our targets by further accelerating reductions from FY2027 onwards. To reach our goal of achieving carbon neutrality by FY2050, we will dedicate 50% of our R&D efforts to development towards carbon neutrality, and will further advance the practical application of new technologies from 2030 onward.

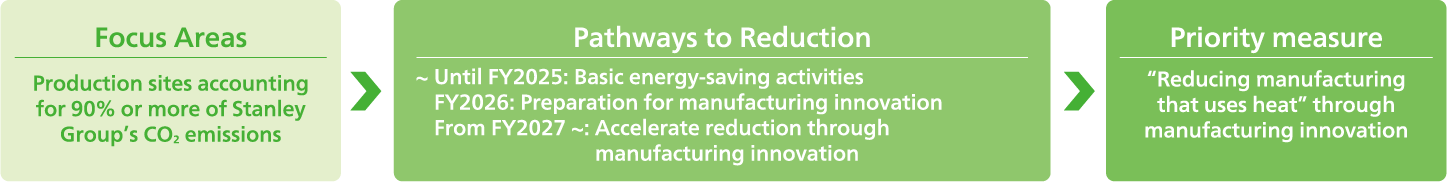

Carbon-neutral initiatives for the supply chain

Monitoring Scope 3 emissions in business activities

Our Group’s initiatives toward becoming carbon neutral have thus far focused on reducing Scope 1 and Scope 2 CO₂ emissions from our business activities. Looking ahead, there will also be a need to address Scope 3, which refers to CO₂ emissions generated from the flow of all processes, including raw materials procurement, logistics and waste. When we calculated our emissions of Group’s Scope 3, we realized that CO₂ emissions from Category ❶ raw materials were the highest. Moreover, out of the raw materials, we first focused on controlling the resin materials that make up 80% of lamps, our core products. The amount of CO₂ emissions for resin was around 500,000 t-CO₂ (in FY2019). Thus, our Group views reducing CO₂ emissions at the resin manufacturing stage a priority issue, and started looking at the practical application of recycled resin as one way to reducing CO₂ emissions. Working together with our suppliers rather than independently is crucial, and we will be focusing on promoting activities for reducing CO₂ emissions to suppliers that have a high level of CO₂ emissions in our supply chain.

Scope3 category

“Green Value Chain Platform” (Ministry of the Environment)

Created using images available on (https://www.env.go.jp/earth/ondanka/supply_chain/gvc/estimate.html)

●figures are Scope3 category

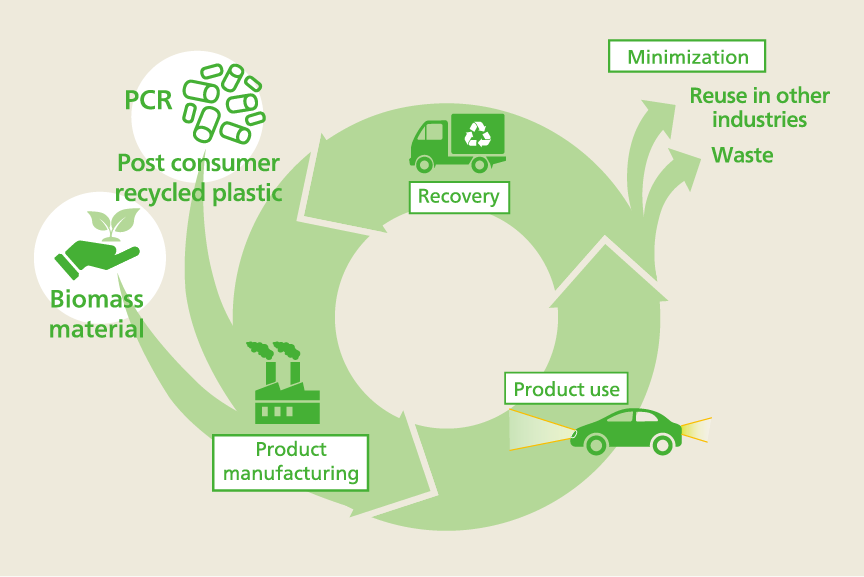

Circular Economy

Basic approach

To ensure the continuation of our business activities while reducing our impact on the global environment, we consider it imperative to transition to a circular economy (CE)*. In this model, resources are recycled and nothing is wasted.

Given that most of the materials used in the Group’s lamp products are petroleum-based resins, we aim to establish a circular resource system in which used materials are recovered after fulfilling their purpose and reused to produce new lamps without extracting additional resources. For this purpose, together with our supply chain, we have laid out and arranged a scheme intended to achieve a recycling-oriented society that minimizes our impact on the environment. Similarly, we will work to develop technologies and products that use sustainable resources to achieve closed-loop recycling.

- A recycling-oriented framework that maximizes the value of existing things by minimizing as much as possible the amount of new resources input or consumed, while designing things and services from the creation stage of economic activities on the premise that they will be recycled and reused.