MEMS Mirror

What is MEMS?

MEMS is an abbreviation for

Micro

Electro

Mechanical

Systems

MEMS is an abbreviation for "Micro Electro Mechannical System" and it is a device/system that includes sensors and actuators.

They incorporates tiny electrical and mechanical elements on a single substrate by applying various microfabrication technologies such as semiconductor manufacturing technology and laser processing technology.

MEMS is a small machine having the following features;

What is MEMS Mirror?

| MEMS Mirror driving method |

MEMS Mirror is actuated by;

piezoelectric, electromagnetic, and electrostatic driving method.

MEMS

Scanning Mirror

-

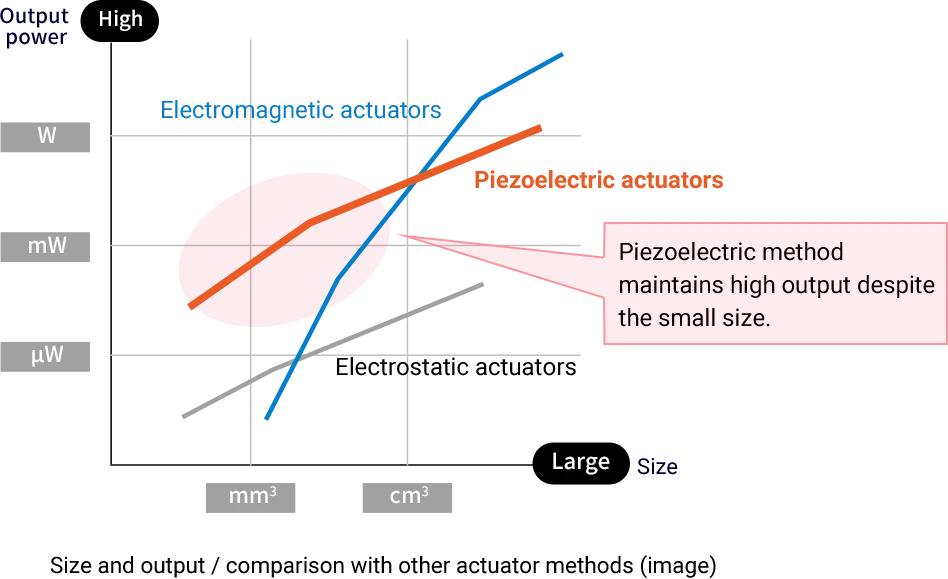

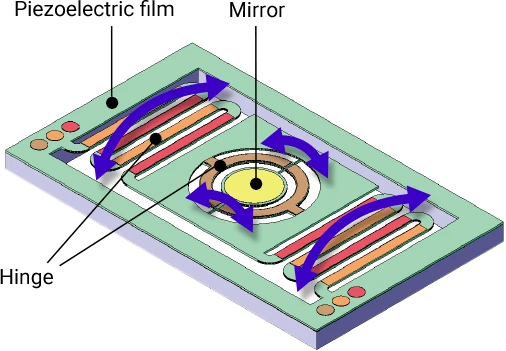

- Piezoelectric

method - A method to actuate mirror by the warping motion caused by application of voltage transmitted to the mirror through the hinge, which is caused by a piezoelectric film deposited on a silicon wafer.

- Piezoelectric

-

- Electromagnetic

method - A method to actuate mirror by passing an electric current through a coil around the mirror in the magnetic field of a magnet.

- Electromagnetic

-

- Electrostatic

method - A method to actuate mirror by electrostatic actuators at both ends of the mirror.

- Electrostatic

Stanley Electric's MEMS Mirror: Applying Piezoelectric Method

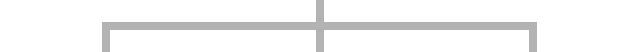

Downsizing: Output power of piezoelectric method becomes more superior as size decreases.

| Structure and actuation of MEMS Mirrors |

Advantages of Stanley Electric's MEMS Mirror

- Capable of high temperature operation:

Original piezoelectric filming technology -high manufacturing technology- - High resistance to external vibration:

Patented bellows (actuator) structure -high device designing technology- - Enables downsizing:

Original piezoelectric filming technology - → Stanley Electric offers highly reliable MEMS Mirror products through its seamless process from "design and deposition to device manufacturing."

| Structure and actuation of MEMS Mirrors |

| Piezoelectric method | Electromagnetic method | Electrostatic method | |

| Device Appearance |

|

|

|

|---|---|---|---|

| Power per unit | ● High 106 - 107N/m2 |

△ Low 101 - 103N/m2 |

△ Low 101 - 104N/m2 |

| Operating environment temperature | ● Automotive qualified 125°C or lower |

× Non automotive qualified 100°C or lower |

● Automotive qualified 150°C or lower |

| Seismic Dynamic Resistance | ● Automotive qualified High |

● Automotive qualified High |

× Non automotive qualified Low |

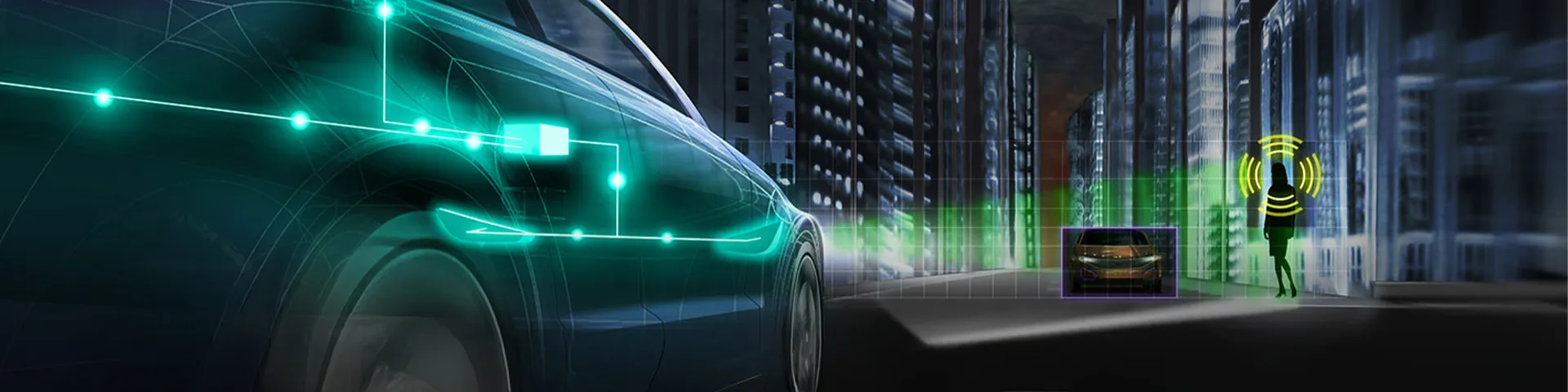

Markets and Applications

Applications where MEMS Mirrors may be used include headlamps, intelligent lighting, mobile projectors, and AR glasses.

Illumination/Lighting

Headlamps

Headlamps Lighting

Lighting Projector

ProjectorImaging + New application

Head Up Display

Head Up Display AR glass / Smart glass / Mobile devices

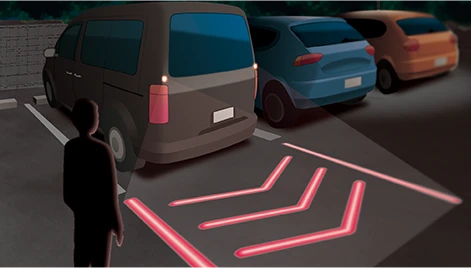

AR glass / Smart glass / Mobile devices Road projection lamp

Road projection lampProjector

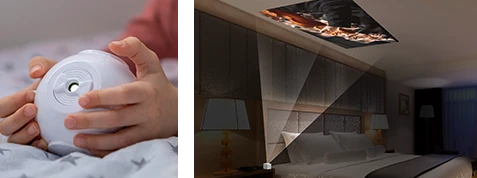

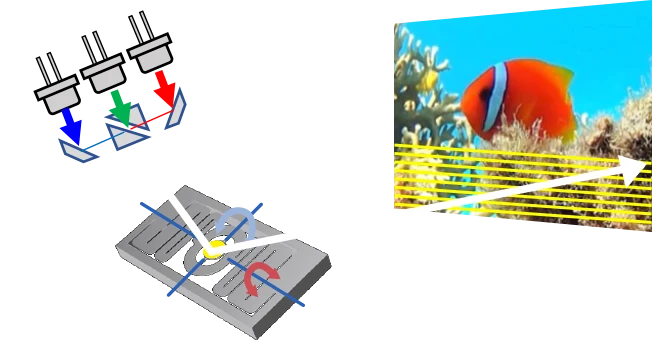

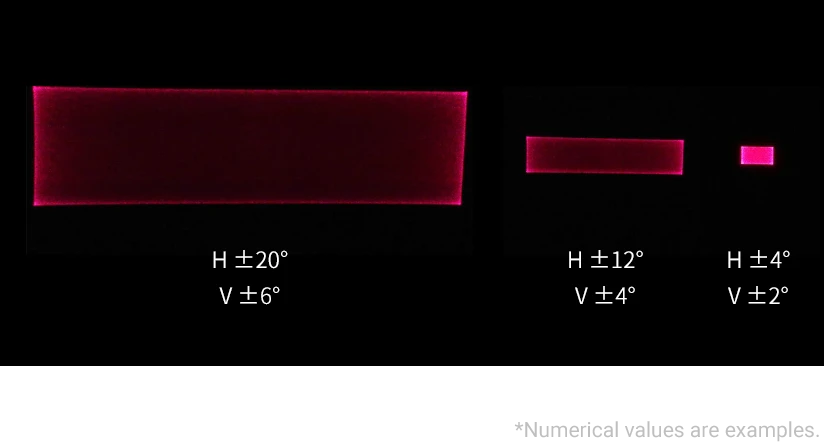

- Projectors using RGB lasers and MEMS Mirrors enable focus-free image projection, and high color gamut regardless of the shape of the projection target (unevenness, distance).

- Taking advantage of its small size, the projector function can be embedded in small mobile devices.

- The image is projected by reflecting and controlling the scanning of RGB tri-color laser beams with a MEMS Mirror device.

- The use of lasers as the image light source enables focus-free, wide color gamut expression from near to far distances.

| MEMS Mirror Projection Principle |

| Demonstration of Raster Scanning |

AR Glass

- Stanley Electric's highly reliable MEMS Mirrors can also be used in medical AR glasses, for people with low vision and other applications to support their daily lives.

- AR glasses are expected to be a next-generation communication platform, and their convenience is expected to increase further along with the evolution of communication technologies such as 5G and 6G.

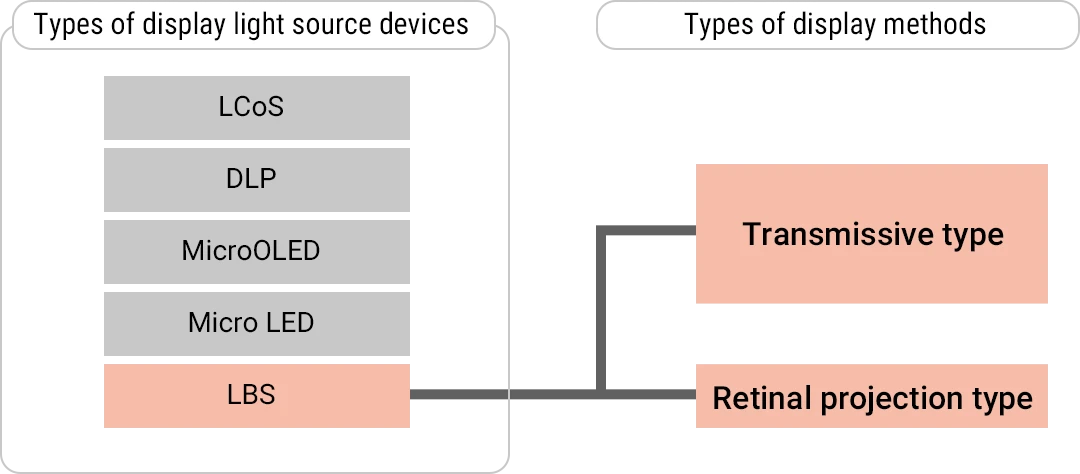

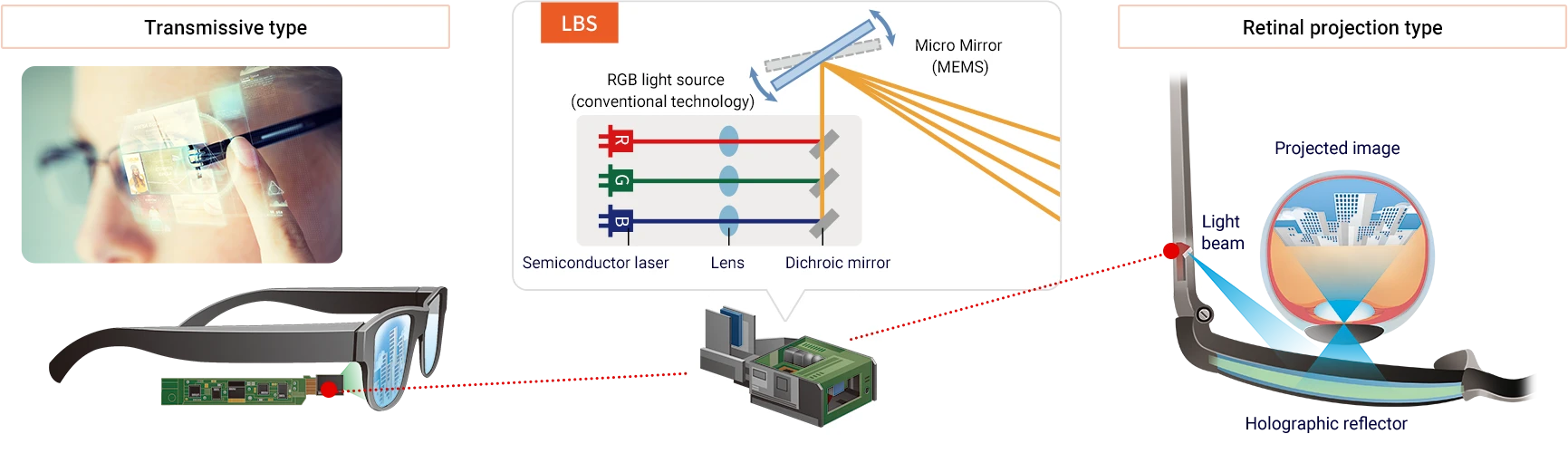

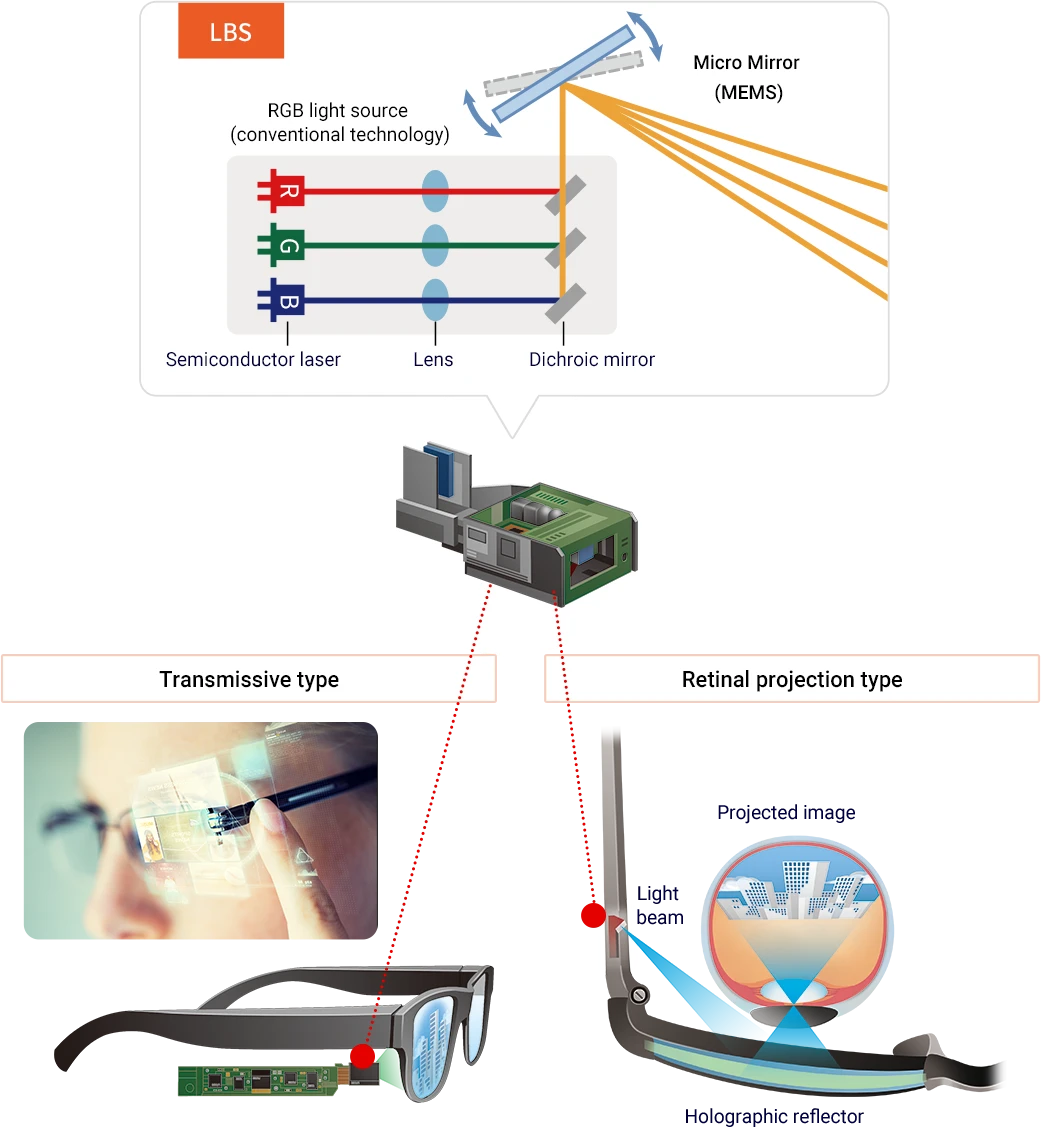

- AR glasses are composed of display light source devices and optical devices. Display light sources generate information images, and optical devices reflect and transmit those information images to the user.

- Laser beam scan (LBS) is one of the display light source devices.This method is used in combination with our MEMS Mirrors.

| Laser beam scanning method |

Lighting

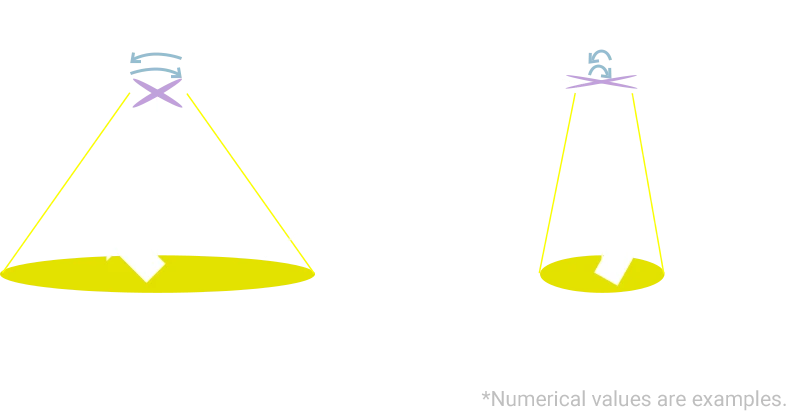

- Achieving active laser irradiation, that can freely manipulate light and change the irradiated area as needed.

- None mechanical parts are used (motors nor other actuators).

→ Downsizing is available. Capable of "spreading," "collecting," and " controlling" light as needed. - Applications:

Stage lighting for entertaining purposes, emergency lighting, security lighting, adaptive headlights for automobiles, etc.

・Adjustable light intensity

・Adjustable irradiation position and shapes

| Laser beam scanning method |

| Image of projecting |Capable of forming random shapes and high-brightness areas

Lineup of MEMS Mirror

(Under Development)

Spec of MEMS Mirror Device (Reference Range)

| Model 1 | Model 2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Parameter | Symbol | Data value | Data value | Unit | Remark | |||||

| Min | Typ. | Max | Min | Typ. | Max | |||||

| H-axis | Resonant Frequency | fh | 35 | 36.5 | 38 | 21 | 21.5 | 22 | kHz | |

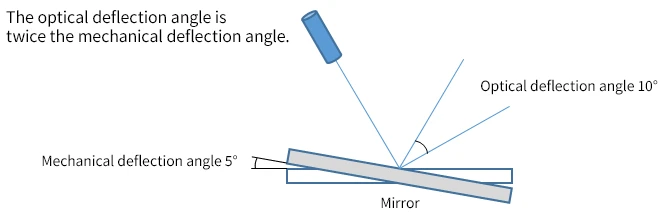

| Driving voltage | Vh | 11 | 13.6 | 17.3 | 9.9 | 13.5 | 18.8 | V | Sinusoidal wave (Resonance mode), at Maximum mechanical deflection angle | |

| Mechanical deflection angle | Θh | -11 | - | +11 | -10 | - | +10 | degree | ||

| V-axis | Resonant Frequency | fv | - | 736 | - | - | 1,074 | - | Hz | |

| Driving voltage | Vv | 41 | 52.3 | 63.5 | 35.7 | 47.1 | 58.5 | V | Sawtooth wave or Triangular wave (Non-resonant mode), at Maximum mechanical deflection angle | |

| Mechanical deflection angle | Θv | -6 | - | +6 | -3 | - | +3 | degree | ||

| Mirror | Size | A | Φ1.06 | Φ1.46 × 1.61 | mm | |||||

| Reflectivity B | Rb | 90 | - | - | 96 | - | - | % | 440-460nm | |

| Reflectivity G | Rg | 90 | - | - | - | - | - | % | 510-525nm | |

| Reflectivity R | Rr | 90 | - | - | - | - | - | % | 632-643nm | |

| Resolution | 1,219 x 840 | 1,164 x 467 | p | |||||||

- Please note that these specifications are subject to change without notice.

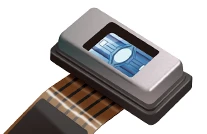

Spec of MEMS Mirror Package (Reference Range)

| Metal package | Ceramic package | |||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Data value | Data value | Unit | Remark | ||||

| Min | Typ. | Max | Min | Typ. | Max | |||

| Incident angle of LD | 17.5 | 45 | degree | |||||

| Operating temperature | -40 | - | 125 | -10 | - | 70 | ℃ | No dew condensation |

| Storage temperature | -40 | - | 125 | -40 | - | 125 | ℃ | No dew condensation |

| Package size | 42.1 x 10 x 4.26 | 15.6 x 7.8 x 2.52 | mm | |||||

| Weight | 4.9 | 0.8 | g | |||||

- Please note that these specifications are subject to change without notice.

We are available prototype products from the above lineup of 2 models and 2 packages, a total of 4 patterns.

Would you please feel free to contact us if you have any requests or questions.