Chronology

- Chapter 1: The Birth of Stanley Electric

- Chapter 2: Taking on the Challenge of Automotive Lamps

- Chapter 3: Development Leading to Products Involving Applied Electronics

- Chapter 4: Accelerating Global Expansion

- Chapter 5: Toward the Next 100 Years

Chapter 1: The Birth of Stanley Electric

1920-1944

Corporate History

Product History

1920

Founding of Kitano Shokai: Starting from Zero

"I want to build the number one business in Japan quickly, even if it means a running a baked sweet potato shop or udon noodle shop. But since we're at the beginning of era of electricity, I'll deal in electrical products that require less capital."

With this in mind, Takaharu Kitano founded Kitano Shokai, the predecessor of Stanley Electric, on December 29. His business was situated in Shiba-ku, Tokyo, which is now Shiba, Minato-ku, Tokyo. He rented a small store that also served as his residence, starting a private shop dealing in automotive light bulbs and other specialty light bulbs.

1921

Commencement of Production and Sales of Automotive Light Bulbs and Other Specialty Light Bulbs

In response to a surge in light bulb exports following World War I, the company began a full-scale manufacturing, sales, and export business, focusing on special-purpose light bulbs, especially those for automobiles.

1923

Recovery from the Great Kanto Earthquake and Trade Name Change to Tokyo Kitano Shokai

The business was damaged by the Great Kanto Earthquake in September. In December of the same year, Takaharu had a building constructed, which served as an office and a factory, and then changed the company's name to Tokyo Kitano Shokai to commemorate its relaunch. Despite the difficult post-earthquake conditions, the company steadily increased sales and became the industry leader in automotive light bulbs, both in terms of domestic sales and exports.

1929

Launched Japan's First Specialty Light Bulb with Permanent Contact Specifications

We released a set of 8 bulbs for Christmas trees. Even if one light were to go out, the remaining seven would remain lit. The specifications were revolutionary.

1932

Meguro Factory Established

At the time, Tokyo Kitano Shokai was a trading company which did not have a manufacturing department. However, in response to the growing need for an in-house integrated system, the company took its first step toward full-scale manufacturing in May 1932, when it built the three-story Meguro Factory in Meguro-ku, Tokyo City, the current location of the company's headquarters.

1933

The Birth of Stanley Electric

On May 5, the company changed its name to Stanley Electric Co., Ltd. The company name was taken directly from the "Stanley" trademark for company's light bulb brand, which had been named after the famous British explorer Henry Morton Stanley. The inclusion of the word "electricity" in the company name was also a sign of the company's intention to make a full-scale entry into the increasingly expanding field of electricity.

1933

Released Baby Light, a Small Flashlight Utilizing Miniature Light Bulbs

When the product was launched as a matchbox-sized flashlight, it grew into a popular product that took the world by storm. There were even numerous imitation products produced by competing companies.

1934

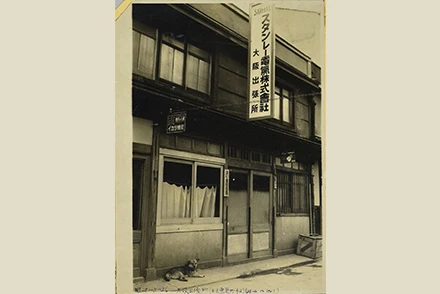

Osaka Branch Established

1935

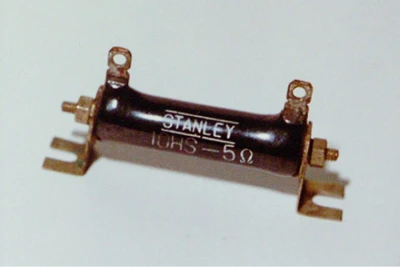

Enamel Resistor Opens New Dimension for Electrical Manufacturers

In parallel with the manufacture of light bulbs, the company began manufacturing enamel resistors. This product, with its high heat resistance and suitability for applications that handle large amounts of power, marked an important milestone in paving the way for development in the electrical field.

1938

Head Office and Sales Office Moved to the Factory Location (Nakameguro)

As business expanded, the distance between the head office and factory became inconvenient, so in November, the head office in Tamura-cho was relocated to the Meguro Factory location to strengthen the link between the head office and factory.

1940

Success in Development of High-Performance Selenium Rectifiers

Selenium rectifiers, which are widely used as rectifiers to supply power, had been considered to pose difficulties when it came to maintaining uniform quality. The company, however, succeeded in developing a high-performance selenium rectifier with excellent voltage resistance and heat resistance. The company was one of the first players to enter this field, a field which brings innovation to the semiconductor industry in Japan.

Chapter 2: Taking on the Challenge of Automotive Lamps

1945-1968

Corporate History

Product History

1945

Starting Over from Scratch

The head office, factory, and warehouse in Nakameguro were all destroyed by fire in an air raid on Tokyo on the night of April 15. When World War II ended, Stanley Electric held a ceremony to dissolve the company. However, in October, in response to earnest calls for the company's restoration from former employees, Stanley Electric held a relaunch ceremony at Shunpuryo dormitory in Nakameguro and began its journey to restore the company.

1946

Launched a Series of Household Electric Heaters

Immediately after the end of the war, when supplies were scarce and people's lives were extremely difficult, there was a strong demand for products closely related to daily life. The company responded to people's needs by developing and selling the portable water heater, an electric heating product for home use that can be put in bath to heat it for bathing, and the electric fermenter, which can be used to ferment foods by performing temperature adjustments in the range of 50°C to 300°C. Amidst a slump in demand for industrial products such as automotive light bulbs and selenium rectifiers, the company contributed to the reconstruction of society by supporting people's lives through the provision of daily necessities.

1947

Resumption of Light Bulb Production

At the end of the war, the supply and demand for light bulbs was extremely tight. However, most of our production facilities were lost in the war and many of our employees did not return from the battlefield. Thus, there was no way to resume operations. However, many customers expressed their desire to see production resumed, and President Takaharu Kitano himself sensed a promising future for automotive light bulbs, and decided to make a fresh start. After more than a year of preparation, the light bulb factory was revived and production of house bulbs and tail lights* resumed.

* house bulbs:Interior lights、tail lights:clearance lamps

1949

The Restoration of Stanley Electric

The company name "Kitano Denki Kogyo Co., Ltd.," which had to be changed during the war, was used for a while after the war. However, on November 1, the company name was changed back to "Stanley Electric Co., Ltd." and the name has been kept to this day.

1956

Entry into the Photoelectric Field

In 1955, we began researching the mass production of selenium photocells by utilizing the technology we had developed for selenium rectifiers. Selenium converts light into electricity, and photovoltaic cells were developed as an application of this property. The following year, in 1956, the company completed the world-class blue selenium photocell, which led to business inquiries coming from light meter manufacturers one after another, and to the beginning of the company's full-scale entry into the photoelectric field.

1957

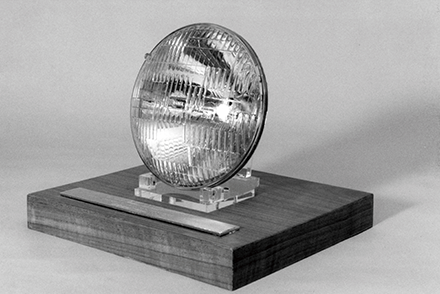

Laying a Foundation for Growth with Metal-Back Sealed Beams

During the period of Japan's rapid economic growth, in response to the rapid expansion of the automobile industry, the company succeeded in developing metal-back sealed beams, which were a new type of dual-gas fully-sealed beam. The price was reduced by 30% when compared to the previous type, and were made available in variety of shapes such as rectangular and horseshoe shapes. The product rapidly became popular in the market and became the foundation for growth in the automotive industry.

1959

The Boom of Built-in Light Meters Which Supported Camera Automation

In 1958, a built-in light meter camera was introduced when the Beauty LM, a beauty camera, was equipped with a photocell light-receiving unit and a light meter unit made by Stanley Electric.

In 1959, in collaboration with Yashica Company, Ltd., we developed a fully automatic light meter which automatically adjusted the aperture and incorporated it into Yashica 8EE. The first electric eye (EE) mechanism in the industry, it attracted a great deal of attention and led the electric eye boom.

1960

Hamamatsu Factory Established

In March, in order to meet the rapid increase in demand for automobiles during Japan's period of high economic growth, the company left Tokyo, where it had outgrown its facilities, and the Hamamatsu Factory was established. Initially, the company assembled and inspected light bulbs and lamps for motorcycles, and later added a one-story steel-frame factory during the second phase of construction. The company established an integrated system that handles everything from pressing to plating and assembly.

Hatano Factory Established

In December, a new comprehensive flagship factory was built in Hadano City, and the first phase of construction was completed on Building No. 1 (electrical component plant). The factory featured modern facilities, being equipped with free dividing structures, lighting, pathways, green belts, and so on. The following year, in 1961, Building No. 2 was completed in the second phase of construction, and the semiconductor and equipment department began operations.

1962

Listed on the First Section of the Tokyo Stock Exchange

1967

Established Stanley Iwaki Works Co., Ltd. as an affiliated company

1968

First Entry into Overseas Markets: Taiwan

As Japanese automakers rapidly expanded their production overseas, the trend toward local production in countries overseas spread to auto parts manufacturers as well. In July, the Company established Taiwan Stanley Electric Co., Ltd. (Taiwan Stanley), which was the first time the company expanded its business overseas.

Chapter 3: Development Leading to Products Involving Applied Electronics

1969-1990

Corporate History

Product History

1969

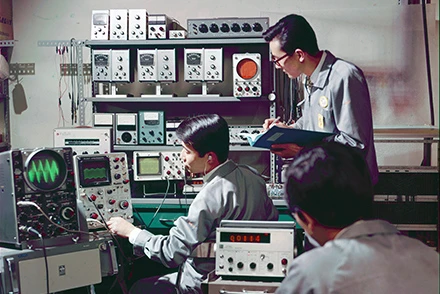

The Launch of Research & Development Laboratory

Aiming to enter new technological and industrial fields, the Research & Development Laboratory was established in Yokohama City on December 8, as a base for the development of original products. The company began to improve the quality of existing products and began taking on challenges in new fields.

1969

Mass Production and Development of Application for Subminiature Lamps

Research began in 1967 and mass production succeeded in 1969. Subminiature lamps, 1.5 to 3 mm in diameter, were used in a wide range of fields, including computers and medical equipment. From 1966, the company began to develop applied products, and in 1970, the Capsule Indicator, which was completed, was highly acclaimed and demand surged. Within one year of launch, sales quadrupled and monthly sales exceeded 100 million yen, making it an important business.

1970

Established Four New Production Facilities as Affiliated Companies in Niigata, Miyagi, Tsuruoka, and Ina

1970

Launch of Japan's First Rectangular Halogen Fog Lamp

In 1968, the company's first fog lamp, the Super Fog, was launched, followed by the Super Fog Wide and Super Fog Cubic, which were well received. Research into halogen lamps began in 1965, and the Stanley Halogen Lamp was launched in 1969. The following year, in 1970, the company introduced Japan's first rectangular halogen fog lamp, opening up a new field in automotive lighting.

1972

Infrared Lamps Open Up the Consumer Electronics Market

In August 1967, we launched an Infrared Yagura Kotatsu using our infrared lamps. Infrared lamp production reached the scale of 1 million units per year in FY1972, with approximately 80% of the lamps delivered to major consumer electronics manufacturers.

1973

Hiroshima Factory Established

Established Hiroshima Factory in Higashihiroshima City to manufacture automotive lighting products.

1973

Began Production of All-Glass Sealed Beams

Following the metal-back sealed beam, which gained popularity for its cost-effectiveness and rectangular design, an all-glass sealed beam with excellent air-tightness was developed. After making original improvements to imported machines, production began at the Hatano Factory in December 1973. In 1974, the company established a full-scale mass-production system, which was adopted by major manufacturers such as Honda Motor Co., Ltd. and Mitsubishi Motors Corporation. In March 1978, four years after mass production began, cumulative production reached 10 million units.

1975

Kitano Foundation of Lifelong Integrated Education Established

On June 23, Chairman Takaharu Kitano established the Kitano Foundation of Lifelong Integrated Education to promote lifelong education. Under the philosophy of giving opportunities for "anyone to study anytime and anywhere," the foundation continues to support people with aspirations through its pillars of fostering of lifelong education, aiding of learners in tuition fees, and providing lectures and training workshops.

1976

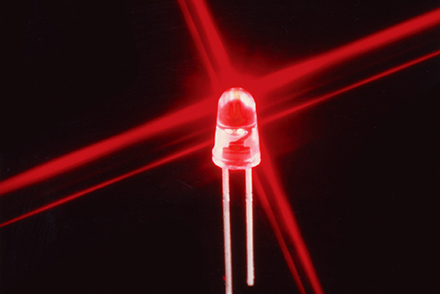

The Development of Continuous Manufacturing Technology for High-brightness Red LEDs

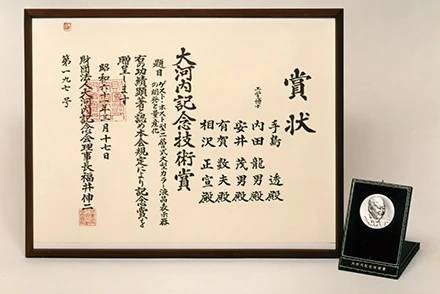

In 1972, Research Development Corporation of Japan (JRDC) commissioned us to conduct research on the practical application of continuous manufacturing technology for LEDs, which was invented by Professor Junichi Nishizawa of Tohoku University. In 1976, we established a continuous manufacturing technology for high-brightness red LEDs with the world's highest brightness of 60 mcd, and began mass production in 1977. In 1979, we developed a high-brightness pure green LED. In 1984, we perfected high-brightness LEDs with 5,000-mcd red, 200-mcd green, and 500-mcd yellow, leading the expansion of the LED application field. The company received the Okochi Memorial Technology Prize (1979) and the Inoue Harushige Prize (1982), and as a "department store of sorts for LEDs," promoted the development of a wide range of applications.

1977

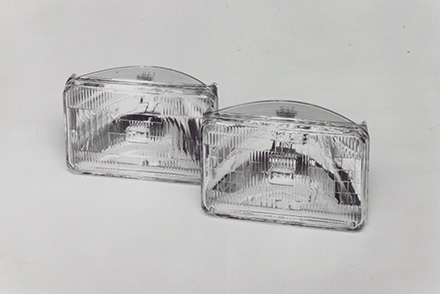

Four-lamp Rectangular All-glass Sealed Beam (Metal-back) Launched

In October, the company succeeded in commercializing a four-lamp rectangular all-glass sealed beam and introduced a fully automated manufacturing machine to begin production. This product was adopted by Mitsubishi Motors Corporation in March 1978 for its Galant Λ (Lambda) Eterna. Then, in August of the same year, a two-lamp rectangular all-glass sealed beam was developed and delivered to Toyo Kogyo for its Capella model.

1979

Established Stanley Electric U.S. Co., Inc. as a Manufacturing base in the U.S.

1980

Established Thai Stanley Electric Public Co., Ltd. as a Manufacturing base in Thailand

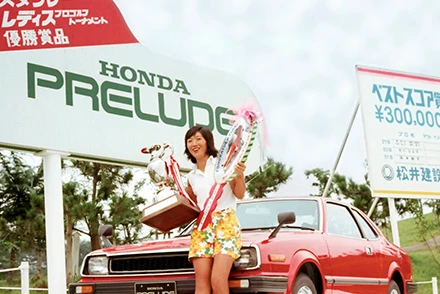

Sponsored the First Stanley Ladies Pro Golf Tournament

With the aim of promoting sports culture and enhancing the company's corporate image through golf, the company hosted the Stanley Ladies Pro Golf Tournament, which has been officially recognized by the Japan Ladies Professional Golfers' Association since 1980. The first tournament was held in Chichibu City, and was televised, which helped raise the company's brand recognition. The event was temporarily suspended in 1993, but was revived in 2003 and has been held to this day.

1981

Okazaki Branch Established

In the late 1970s, the company faced the challenge of increasing its production capacity for electrical components, and in 1980 acquired a site for a new factory in Okazaki City. Production began in 1981, with a monthly production capacity of over 500,000 headlamps and rear combination lamps. Since then, the company has expanded the site and constructed a streamlined factory to improve production efficiency and operating rates.

1981

Developed the World's First Color LCD Display System, the Two-layer GH

At the time, the mainstream TN-type LCD was limited to one display color, but in 1981, the world's first color LCD display system, the Two-layer GH, was developed. It is brighter than the TN type and provides superior visibility, with the color display having been realized as a result of the technology involving the integration of liquid crystals and dyes. Production and sales began in May 1981, and mass production began in 1983 for office automation equipment and industrial equipment. Furthermore, full-scale production of dot-matrix color LCDs began in 1984, and these were adopted as display panels for automobiles. The two-layer GH LCD received the 32nd Okochi Memorial Prize in 1985 and the Science and Technology Agency Director-General Award in 1986 for its innovation and performance.

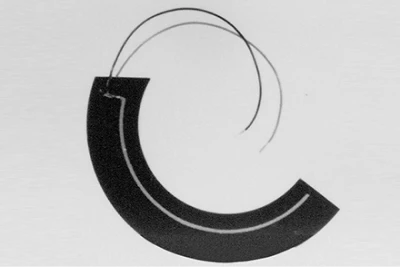

Gyro Sensors Adopted for the Honda Electro Gyrocator

The helium-filled gas rate type gyrometer was used as the direction sensor in the system of Honda Electro Gyrocator, the world's first map-based automotive navigation system developed by Honda Motor Co., Ltd. in 1981. We provided the vacuum and filament technologies necessary to achieve such high precision. We succeeded in achieving the world's highest vacuum conditions, and the precision control technology it developed led to the electronic circuit business which it later became involved with. In March 2017, this system was selected for IEEE Milestone, which involves the recognition of historical achievements in the electrical and electronic fields.

Honda Electro Gyrocator

1985

Developed the World's First MR (Multi Reflector) Headlamps

Development of multi-reflector (MR) headlamps, which offer increased light intensity, improved design flexibility, and maintain costs by eliminating lens cuts and using reflectors to achieve light distribution. This technology was presented at the SAE International Conference in 1987 and was first used in the Honda Accord in 1989. It transformed the history of automotive front lighting and developed into the "freeform surface headlamps" that are the mainstream today.

1986

Established Utsunomiya Technical Center

In August, the Utsunomiya Technical Center was established in Utsunomiya City. It was established to accelerate product development and design to meet the needs of research & development base of Honda Motor Co., Ltd. The facility was equipped with the latest CAD software, various testing facilities, and a prototype production line, and also housed a sales department, creating an integrated system for technology and sales.

Established II Stanley Co.,Inc. as a Manufacturing Base in the U.S.

1986

Equipped with the World's First LED High Mounted Stop Lamps Which Began to Become Popularized in Japan

In 1984, when high mount stop lamps became mandatory in the U.S., we set up a dedicated line to meet U.S. demand and address the increasing popularization taking place in Japan, and secured a 60-70% share of the domestic market. In 1986, our LED high mounted stop lamps were installed in the North American model of the NISSAN FAIRLADY Z for a world's first. In the following month, we launched the LeDON rear spoiler with LED stop lamps for the aftermarket. In Japan, LED high mounted stop lamps embedded into rear spoilers were adopted as an option for Toyota Soarer. After that, LED high mounted stop lamps rapidly became popular in Japan.

1987

Established Asian Stanley International Co., Ltd. as a Manufacturing Base in Thailand

1988

Established STANLEY-IDESS S.A. as a Sales Base in France

1989

Rebuilding the Hatano Factory

In September 1987, a large fire broke out in Building No. 2 of the Hatano Factory. Fortunately, there were no casualties, but the factory did burn to the ground. The disaster prompted construction of a new state-of-the-art Building No. 2, which was completed in August 1989. The factory was re-launched as a high-tech factory equipped with productivity and a comfortable work environment, and was also awarded the excellence award at the Kanagawa Architecture Concours.

Chapter 4: Accelerating Global Expansion

1991-2011

Corporate History

Product History

1991

Established the Yokohama Technical Center

In August, the Yokohama Technical Center was established in Yokohama City as a development base for the LED and automotive electronics businesses. Approximately 120 people from the head office, the Hatano Factory, and the Utsunomiya Technical Center, were brought together to share technical know-how and improve development speeds so that the entire process spanning from LED device development to application development could be handled consistently. With state-of-the-art facilities and an environment that encouraged creativity, the company created a series of new products such as Electronic information boards and large displays.

1993

Established Stanley Electric (H.K.) Co., Ltd. as a Sales Base in Hong Kong

Acquired Shares of Matsuo Electric Co., Ltd. and Made it a Special Subsidiary

1993

Launched RAYBRIG Hyper Halogen, the World's First High-efficiency Bulb Providing Light Close to Sunlight

In September, the next-generation lamp brand RAYBRIG* was launched and the world's first high-efficiency RAYBRIG Hyper Halogen bulb was released. It was a revolutionary product that provided white light that was close to that of sunlight, was compatible with resin lenses due to the small battery load, and could be easily installed by simply replacing the bulb. Despite being about three times the price of conventional products, 1.2 billion yen worth of the product was sold in the first seven months of its launch. It generated a huge response, with sales channels being expanded to mass retailers as well.

* Merged into the Stanley Electric brand on March 31, 2021

1994

Yamagata Factory Established

In April, established Yamagata Factory, a dedicated facility for LED devices, in Tsuruoka City.

1995

Established Tianjin Stanley Electric Co., Ltd. as a Manufacturing Base in China

Formulated SNAP Production Innovation Activity

SNAP (Stanley New Approach for higher Productivity) was introduced to improve the efficiency of the production process. In 1997, the company received guidance from the PEC Industrial Education Center, which had much experience with the implementation of the Toyota Production System at many companies, leading to the company achieving genuine results.

1996

Established Vietnam Stanley Electric Co.,Ltd. as a Manufacturing Base in Vietnam

Established Shanghai Stanley Electric Co., Ltd. as a Sales Base in China

Full-scale Motor Sports Support Activities

In 1995, the company became a sub-sponsor of TEAM KUNIMITSU, one of Japan's leading teams. The team won three endurance races in the same year: 24 Hours of Le Mans, Tokachi 24 Hours, and the Suzuka 1000km. The following year, in 1996, the company became the main sponsor and the RAYBRIG blue NSX made its first appearance. HID was installed in headlamps to support night driving. In 1997, the company competed in SUPER GT and the RAYBRIG brand became widely known through motorsports.

1996

Commercialization of the High Intensity Discharge (HID) Headlamps for Japanese Cars

In 1985, the company began researching High Intensity Discharge (HID) headlamps using metal halide lamps. We overcame difficulties such as delays in the development of regulations and in 1995 obtained approval for production of the first such product in Japan. The following year, in 1996, it was installed in the Mitsubishi Fuso Super Great, making it the first domestic product to be put to practical use.

1998

Established Stanley Electric Sales of America, Inc. as a Sales Base in the U.S.

Established Stanley Electric GmbH as a Sales Base in Germany

Established STANLEY WELL Corporation as a Special Subsidiary

2000

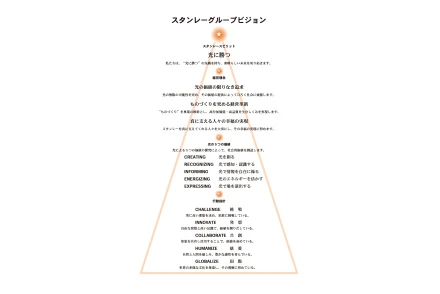

Stanley Group Vision Established

In April, the Stanley Group Vision was established as a new set of guidelines encompassing the existing company creed and corporate philosophy. The vision was based on the Stanley Sprit being an "Outshining Light" and consisted of the management philosophy, five values of light, and action guidelines, and was positioned as an expression of the company's unchanging goals for the future. The company declared that it is a manufacturer which provides value by making products in the optics-related field.

2001

Established Stanley Electric(U.K.)Co., Ltd. as a Sales Base in in the U.K.

Established Suzhou Stanley Electric Co., Ltd. as a Manufacturing Base in China

Established Stanley Electric Hungary Kft. as a Manufacturing Base in Hungary

Established PT. Indonesia Stanley Electric as a Manufacturing Base in Indonesia

2001

Developed the world’s first seven-lens headlamp adopted for the Nissan Cima

Introduced in a New Year’s Day newspaper advertisement, the headlamp attracted significant attention. Through extensive prototyping and refinement, it achieved optical performance befitting a flagship model and received high acclaim.

2002

Established Shenzhen Stanley Electric Co., Ltd. as a Manufacturing Base in China

Established Guangzhou Stanley Electric Co., Ltd. as a Manufacturing Base in China

2004

Established the Hamamatsu Branch

Established Hamamatsu Branch in Hamamatsu City to produce automotive lighting equipment.

2004

World's First Xenon Strobe for Cell Phones

A xenon-type auto strobe developed by the company was installed in a Kyocera cell phone, giving birth to the world's first full-fledged strobe-equipped cell phone. It enabled photography with high image quality that could not be obtained with a conventional LED flash, and encouraged the evolution of camera-equipped cell phones.

2005

Established Stanley Electric Korea Co., Ltd. as a Sales Base in South Korea

2007

Established the Opto Technical Center

In July, the company established the Opto Technical Center in Yokohama as a base to consolidate its technical capabilities and knowledge in the LED business. The company strengthened its market competitiveness by concentrating on functions other than manufacturing, such as planning, design, and evaluation.

2009

Established Stanley Electric do Brasil Ltda. as a Manufacturing Base in Brazil

2009

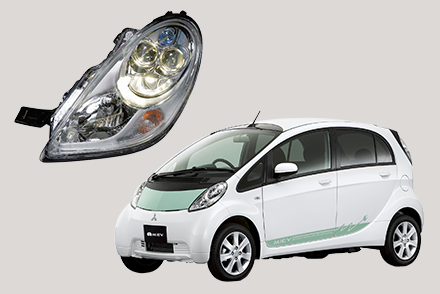

Our First LED Headlamp Adopted for Mitsubishi’s i-MiEV, the World’s First Mass Produced Electric Vehicle

The practical design of our LED headlamps was completed in 2008 and proposed for Mitsubishi’s i-MiEV, the world’s first mass-produced electric vehicle. In 2009, they were adopted and entered mass production as our first LED headlamps.

At the time, white LED headlamps—positioned as a next-generation light source—faced challenges such as insufficient luminous intensity and high power consumption. Through continued development, we ultimately achieved performance comparable to that of HID headlamps.

2011

Established Wuhan Stanley Electric Co., Ltd. as a Manufacturing Base in China

Established Stanley Electric Sales of India Pvt. Ltd. as a Sales Base in India

Chapter 5: Toward the Next 100 Years

2012-Present

Corporate History

Product History

2012

New Head Office Building Completed

The head office building was reconstructed due to issues such as declining disaster preparedness due to aging, with the new building being completed in December. A seven-story building with one basement floor, the office serves as a hub for global communications, providing a base for speedy decision-making and communication of information. The office building was selected for the Architectural Excellence Award of 2013 by the Architectural Institute of Japan and received the 47th SDA Sign Design Excellence Award.

2012

Developed the World's First High Contrast LCD

In April, the company released S-PBTLCD (Special-Pure Black Technology LCD), a high-contrast LCD that overcomes the narrow viewing angle that has been a weak point of LCDs and was the world's first LCD dedicated to text display that is clearly visible from any angle. The product was highly evaluated by hot-water heater manufacturers and adopted by overseas manufacturers for residential and industrial equipment.

2013

Established Shenzhen Stanley Electric Co., Ltd. as a Sales Base in China

2014

LED Headlamps Adopted for the First Time in Motorcycles

We developed LED headlamps for motorcycles, which were adopted for the first time in Japan in the KAWASAKI Z1000. This product uses a direct light method where no reflector is used, with its complexly shaped resin lens distributing LED light efficiently. This resulted in the world's smallest four-light design.

2015

Established Stanley Electric Manufacturing Mexico S.A. de C.V. as a Manufacturing Base in Mexico

Established Tianjin Stanley Electric Technology Co., Ltd. as a Manufacturing Base in China

2015

Headlamps Featuring Adaptive Front-lighting (ADB) for Enhanced Nighttime Visibility

Headlamps equipped with Adaptive Driving Beam (ADB) technology use an onboard camera to detect surrounding traffic and road conditions, providing high-beam–level visibility while automatically preventing glare for oncoming and preceding vehicles. This technology was first introduced on the Mazda CX-5.

2016

LED Floodlights with Ultra Narrow Light Angle Adopted for Niagara Falls Illumination

In December, 1,400 ultra-narrow LED floodlights illuminated Niagara Falls. With a distance of up to 600 meters, and even under the harsh conditions of low temperatures and high humidity, it achieves high-precision illumination that suppresses diffuse reflection of light, and was awarded the IES Illumination Awards in 2017, the world's most prestigious awards in the lighting field.

Development of the World's First Viewing Angle Switching Backlight

The company developed the world's first "Privacy Back Light," which uses two light guide plates and LEDs placed on the left and right sides to change the way light travels according to the on/off status of the PC's privacy function. The high precision and weight-related issues in manufacturing were overcome, and the product was incorporated into the HP EliteBook series.

2019

Established the Minatomirai Technical Center

Established Stanley Electric Philippines Inc. as a Manufacturing Base in the Philippines

2020

Constructed the Light Tunnel Building, One of the World's Longest Indoor Testing Facilities

The new Light Tunnel Building was constructed, which would be one of the world's longest indoor testing facilities (with four lanes of 220 meters in length and 21 meters in width) and capable of reproducing all weather conditions (rain, fog, day and night). The facility includes an outdoor driving test track for dynamic evaluations involving pedestrians, oncoming vehicles, and vehicles ahead, and an outdoor static test area for static light distribution evaluations. This allows for verification to be undertaken with actual vehicles in any environment.

Established HexaTech, Inc. as a Manufacturing Base in the U.S.

Design Engineering Building constructed on land adjacent to the Light Tunnel

The Design Engineering Building adjacent to the Light Tunnel Building has been completed.It is equipped with a full-scale vehicle inspection area and driving simulator facilities.By integrating light sources, light distribution, structure, circuitry, and control functions into a single facility, a system has been established that enables end-to-end lamp system development.

Celebrated the company's 100th anniversary

2020

Enhancement of Deep Ultraviolet LED Technology and Deployment of Sterilization Solutions

In January 2017, the company signed an agreement with Tokuyama Corporation to acquire technology and equipment for deep ultraviolet LEDs. In March 2019, HexaTech, Inc., a world leader in large-diameter, defect-free aluminum nitride crystals, became a subsidiary of the company, enabling the Group to produce everything from semiconductor substrates to LED packages. Then, in May of the same year, the world's highest output level was achieved at the 265nm wavelength. Joint testing with Yamaguchi University has confirmed the effectiveness against the new coronavirus, meaning that we provide sterilization solutions that meet customer needs.

2021

Launched the Ultraviolet Product Brand, AℓNUV

AℓNUV, a brand of deep ultraviolet products, was launched to offer a variety of products and solutions for surface, air, and water sterilization applications, focusing on the sterilizing effects of deep ultraviolet light sources.

The AℓNUV brand visualized the technologies for 265-nm LEDs and 254-nm cold-cathode ultraviolet lamps which both offered powerful disinfection capability, as well as for light source modules and systems which had an increased variation of light source wavelengths. This was how the company's products were distinguished. The brand name AℓNUV was a coined term that combined "AlN" (aluminum nitride substrate) and "UV" (ultraviolet).

2024

Established Thai Stanley Electric Public Co., Ltd. as a Manufacturing Base in Thailand

Established Stanley-Angstrom Electric da Amazonia Ltda. as a Manufacturing Base in Brazil

2024

Development of the World's First Matrix LED ADB Headlamp for Motorcycles

The world's first headlamp with adaptive driving beams (ADB) was developed for motorcycles. This product not only automatically adjusts the illumination area to avoid making things too bright for oncoming and preceding vehicles, but also changes the light distribution pattern in response to the leaning of the vehicle when cornering to achieve high visibility when turning. The product was adopted for use in the YAMAHA TRACER 9 GT, it has made a significant contribution to improving nighttime riding safety for motorcycles.