Stanley's 100th Anniversary Site

Towards Becoming an Optoelectronics Enterprise

After building steady domestic foundations, Stanley Electric began to develop light-emitting diodes (LED) in 1969. LED's applications were drastically expanded by the improvements of luminous efficiency as well as development of a continuous manufacturing technology. As the automotive industry was shifting towards overseas production, the Stanley Electric was also expanding its overseas production bases. At that time, the company also developed innovative automotive equipment. These included multi-reflector headlamps whose reflectors had a photometric control function whereas conventional reflectors (reflective surfaces) only had a light collection function. That was an evolution of headlights from conventional functional parts into design parts. From the 1970s to 1980s, the company created groundbreaking products one after another to grow into an optoelectronics enterprise based on its prominent technologies.

CHRONOLOGY

-

1971

-

Dec.

Launched light-emitting diodes (red LEDs)

-

-

1972

-

Nov.

Launched miniature strobe for photographs

-

-

1973

-

Apr.

Increased capital stock to 2,035,000,000 JPY

-

Launched green LEDs

-

Aug.

Opened the Hiroshima Factory

-

Dec.

Started to manufacture all-glass sealed beams

-

-

1975

-

Jan.

Launched yellow LEDs

-

Feb.

Opened the Kumamoto Factory

-

Jun.

Established the Kitano Foundation of Lifelong Integrated Education

The Establishment of the Kitano Foundation of Lifelong Integrated Education

On June 23, 1975, the Kitano Foundation of Lifelong Integrated Education was established. This foundation was made possible through the monetary donation from Chairman Takaharu Kitano. In his youth, Takaharu had to give up his studies due to an illness, so this foundation is designed to provide opportunities for "anyone to study anytime and anywhere" and to promote "lifelong" education fit for the 21st century. Its operations consisted of three pillars: fostering lifelong education, aiding learners in tuition fees, and providing lectures and training workshops.

Relief at the entrance hall of the foundation

Takaharu Kitano, founder

-

Sep.

Four-lamp rectangular metal-back sealed beams on GM cars

The Establishment of the Kitano Foundation of Lifelong Integrated Education

On June 23, 1975, the Kitano Foundation of Lifelong Integrated Education was established. This foundation was made possible through the monetary donation from Chairman Takaharu Kitano. In his youth, Takaharu had to give up his studies due to an illness, so this foundation is designed to provide opportunities for "anyone to study anytime and anywhere" and to promote "lifelong" education fit for the 21st century. Its operations consisted of three pillars: fostering lifelong education, aiding learners in tuition fees, and providing lectures and training workshops.

Relief at the entrance hall of the foundation

Takaharu Kitano, founder

-

-

1976

-

Jul.

Continuous manufacturing technology of LEDs was recognized as a success by the Research Development Corporation of Japan

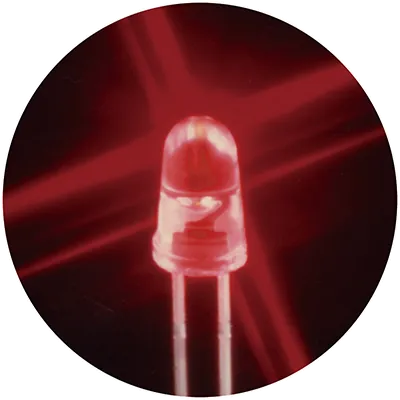

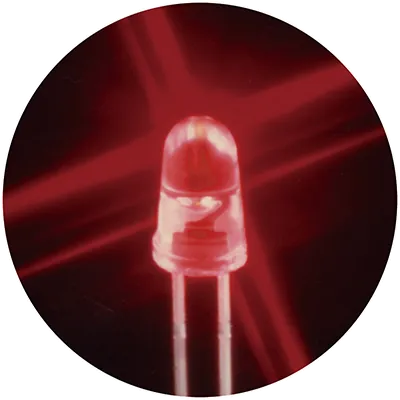

The Development of Continuous Manufacturing Technology for High-brightness Red LEDs

In 1969, Stanley Electric started to develop light-emitting diodes (LEDs). That was one year after the U.S. Apollo spacecraft used LEDs for the first time in the world. Three years later in October 1972, the company was commissioned by the Research Development Corporation of Japan (currently the Japan Science and Technology Agency) to develop continuous manufacturing technology for LEDs into practical use. The technology was an ingenious invention by Dr. Junichi Nishizawa, a Professor at Tohoku University. Being commissioned was an honor, developing this technology into practical use was an extremely difficult task. As a result of hard work, in July 1976, the company successfully developed continuous manufacturing technology for high-brightness red LEDs with the world's highest brightness of 60 mcd (millicandela). In 1977, the company started to mass-produce high-brightness red LEDs.

The development of continuous manufacturing technology for high-brightness LEDs won an Okochi Memorial Technology Prize in 1979, as well as an Inoue Harushige Prize in July 1982.

In January 1979, Stanley Electric developed high-brightness pure-green gallium-phosphide (GaP) LEDs, which became a hot seller. Then, in 1984, the company developed 5000-mcd red, 200-mcd green, and 500-mcd yellow LEDs as a milestone achievement in the company's LED development. These LEDs were revolutionary products that offered about twice the brightness of conventional products, so they attracted a lot of attention from domestic and foreign industries. The high-brightness LEDs were originally available in red only, but the addition of green made it possible to use a pair of red and green. This had a great significance and then led to the dramatic expansion of LED's application.

The company rapidly expanded their application to audio equipment, home appliances, cameras, measuring instruments, terminal equipment, automatic vending machines, and toys by developing products one after another under the catchphrase of "department store for LEDs."

The world's brightest Light-emitting diode (red LED)

-

Oct.

Increased capital stock to 3,249,000,000 JPY

The Development of Continuous Manufacturing Technology for High-brightness Red LEDs

In 1969, Stanley Electric started to develop light-emitting diodes (LEDs). That was one year after the U.S. Apollo spacecraft used LEDs for the first time in the world. Three years later in October 1972, the company was commissioned by the Research Development Corporation of Japan (currently the Japan Science and Technology Agency) to develop continuous manufacturing technology for LEDs into practical use. The technology was an ingenious invention by Dr. Junichi Nishizawa, a Professor at Tohoku University. Being commissioned was an honor, developing this technology into practical use was an extremely difficult task. As a result of hard work, in July 1976, the company successfully developed continuous manufacturing technology for high-brightness red LEDs with the world's highest brightness of 60 mcd (millicandela). In 1977, the company started to mass-produce high-brightness red LEDs.

The development of continuous manufacturing technology for high-brightness LEDs won an Okochi Memorial Technology Prize in 1979, as well as an Inoue Harushige Prize in July 1982.

In January 1979, Stanley Electric developed high-brightness pure-green gallium-phosphide (GaP) LEDs, which became a hot seller. Then, in 1984, the company developed 5000-mcd red, 200-mcd green, and 500-mcd yellow LEDs as a milestone achievement in the company's LED development. These LEDs were revolutionary products that offered about twice the brightness of conventional products, so they attracted a lot of attention from domestic and foreign industries. The high-brightness LEDs were originally available in red only, but the addition of green made it possible to use a pair of red and green. This had a great significance and then led to the dramatic expansion of LED's application.

The company rapidly expanded their application to audio equipment, home appliances, cameras, measuring instruments, terminal equipment, automatic vending machines, and toys by developing products one after another under the catchphrase of "department store for LEDs."

The world's brightest Light-emitting diode (red LED)

-

-

1977

-

Jan.

Launched LED numeric indicators

-

Aug.

Launched the four-lamp rectangular sealed beam (metal-back) approved as the first type designation by Japan's Ministry of Transport

-

-

1978

-

Jan.

Launched the first orange high-brightness LEDs in Japan

-

Mar.

Total number of all-glass sealed beams produced reached 10 million

-

Apr.

Increased capital stock to 4,080,000,000 JPY

-

-

1979

-

Jan.

Developed pure green high-brightness LEDs

-

Sep.

Started the production of liquid crystal displays

-

Oct.

Established Stanley Electric U.S. Co., Inc. (SUS) in the U.S.A. (relocated to London, Ohio in April 1981)

-

Developed color LCDs

-

-

1980

-

Mar.

The development of continuous manufacturing technology for high-brightness LEDs won the 26th Okochi Memorial Technology Prize

Okochi Memorial Technology Prize

The development of continuous manufacturing technology for high-brightness LEDs won the 26th Okochi Memorial Technology Prize

-

May

Established Thai Stanley Electric Co., Ltd. (THS)

-

Jun.

Developed flat fluorescent lamps for LCD backlight illuminations

-

Aug.

Launched high-brightness numeric indicators series (four color LED)

-

Sponsored the First Stanley Ladies Pro Golf Tournament

Poster of the First Stanley Ladies Pro Golf Tournament

Nayoko Yoshikawa, winner of the First Tournament

-

Oct.

Concluded a technical assistance agreement with Samlip Industrial Co., Ltd. of South Korea

-

Okochi Memorial Technology Prize

-

The development of continuous manufacturing technology for high-brightness LEDs won the 26th Okochi Memorial Technology Prize

-

Poster of the First Stanley Ladies Pro Golf Tournament

-

Nayoko Yoshikawa, winner of the First Tournament

-

-

1981

-

Apr.

Launched LED level meter with 5- and 10-aligned rectangular LEDs

-

May

Held a general exhibition celebrating the 60th anniversary

-

Takaharu Kitano, Founder and Chairman Emeritus, passed away

-

Jul.

Concluded a technical assistance agreement with HELLA Australia

-

Sep.

Opened the Okazaki Factory

-

Oct.

Launched surface display LEDs in the colors of red, green, yellow, and orange

-

-

Gyro Sensors on the Honda Electro Gyrocator

Honda Electro Gyrocator

-

-

1982

-

Apr.

Launched high-sensitivity photodetector, silicon P type photo transistor

-

Jul.

The development of continuous manufacturing technology for high-brightness LEDs won the 7th Inoue Harushige Prize

-

-

1983

-

Mar.

Developed large display panels using color LCDs

-

May

Developed 2000-mcd high-brightness red LEDs

-

Sep.

Increased capital stock to 6,792,000,000 JPY

-

Oct.

Tsukuba Research Consortium was established

-

-

1984

-

May

Concluded a technical assistance agreement with LUMAX of India

-

Jul.

Developed 5000-mcd high-brightness red LEDs

-

Sep.

Opened the Tsukuba Research Laboratory

-

Dec.

Launched Pure Green, a high-brightness pure green LED with a brightness twice that of conventional models

-

-

1985

-

Jun.

Appointed then-President Takaoki Kitano as Chairman and then-Vice President Toru Teshima President

-

Sep.

Newly established Management Meeting

-

Oct.

Developed and launched super high-power IR diodes

-

-

Developed MR (Multi Reflector) headlamps

The Development of MR Headlamps

In 1985, Stanley Electric successfully commercialized multi-reflector (MR) headlamps. MR headlamps did not have lens ridges on their front glass surface. Their reflectors (mirrors) had light diffusion and photometric functions, which conventionally were provided by lens ridges, and their front glasses simply functioned as a see-through cover. They were the world's first headlamps without lens ridges as well as the world's first to have reflectors that were created using CAD/CAM.

Later, this technology was also applied to the development of "freeform surface headlamps". It was a historic technology that allowed the evolution of headlamps from functional parts to design parts, and to this day still remains the mainstream in headlamp design.

Multi-Reflector (MR) headlamps without ridges for light distribution

-

-

1986

-

Feb.

The high power IR LEDs won an award at the Nikkei Superior Products and Services Awards

-

Mar.

The development and mass-production of two-layer guest-host large color LCDs won the technology prize at the 32nd Okochi Memorial Technology Prize

The Development and Manufacturing of Color LCDs That Drew the World's Attention

Starting research on LCDs in 1975, Stanley Electric was a late starter in their development. Mainstream LCDs at that time were twisted nematic (TN) type, where the liquid crystals were sandwiched between two polarizers, and their display color was limited to one. With an aim of advancing to a leading position in the development race by developing a principle for producing a clear color, the company sought for a collaborative development with the person who first introduced liquid crystal display to Japan: Professor Masanobu Wada of Tohoku University.

Six years later, the company finally developed the world's first two-layer guest-host (GH) LCD that allowed color display, and then began its production and sales in full swing. This two-layer GH LCD was capable of multi-color display, so its potential for wider applications in the information industries was very high, with automotive displays being one of them. Immediately after it was unveiled, this color LCD attracted attention of automotive manufacturers from around the world and was selected for France's Renault R-11 compact sedan. Afterward, it was used as dashboard displays for the Toyota Corona and the Honda Accord to the limelight of various industries. In 1986, the company's development and mass-production of two-layer guest-host large color LCDs won a technology prize at the 32nd Okochi Memorial Prizes. This was the second honorable prize that the company's iconic optoelectronics product received, following the LEDs at the 26th edition of the Prizes.

Large color LCD panel on the Toyota Corona dashboards

-

Aug.

Started the mass production of LED high mounted stop lamps

-

Opened the Utsunomiya Technical Center

-

Nov.

Established II Stanley Co., Inc. (IIS)

-

-

Strobes on the Utsurun Desu, the first-generation film-with-lens camera of FUJIFILM Corporation (first in Japan)

Strobes on Utsurun Desu FLASH, a film-with-lens camera (1987 model)

The Development and Manufacturing of Color LCDs That Drew the World's Attention

Starting research on LCDs in 1975, Stanley Electric was a late starter in their development. Mainstream LCDs at that time were twisted nematic (TN) type, where the liquid crystals were sandwiched between two polarizers, and their display color was limited to one. With an aim of advancing to a leading position in the development race by developing a principle for producing a clear color, the company sought for a collaborative development with the person who first introduced liquid crystal display to Japan: Professor Masanobu Wada of Tohoku University.

Six years later, the company finally developed the world's first two-layer guest-host (GH) LCD that allowed color display, and then began its production and sales in full swing. This two-layer GH LCD was capable of multi-color display, so its potential for wider applications in the information industries was very high, with automotive displays being one of them. Immediately after it was unveiled, this color LCD attracted attention of automotive manufacturers from around the world and was selected for France's Renault R-11 compact sedan. Afterward, it was used as dashboard displays for the Toyota Corona and the Honda Accord to the limelight of various industries. In 1986, the company's development and mass-production of two-layer guest-host large color LCDs won a technology prize at the 32nd Okochi Memorial Prizes. This was the second honorable prize that the company's iconic optoelectronics product received, following the LEDs at the 26th edition of the Prizes.

Large color LCD panel on the Toyota Corona dashboards

-

-

1987

-

Mar.

Developed LED print heads

-

Apr.

Amended the mandatory retirement system to extend the retirement age to 60

-

Sep.

Fire broke out at the Semiconductor Plant 1 of Hatano Factory, and the Building 2 was completely destroyed

The Complete Destruction of the Hatano Factory's Building 2 by Fire

On September 11, 1987, a fire broke out at the Semiconductor Plant 1 in Building 2 of the Hatano Factory. Although there were no casualties, Building 2 was completely burned down. The fire was probably caused by the overheating of parts of photoconductor production facilities.

Immediately after the fire was extinguished, employees carried out restoration work for Building 2 under the slogan of "don't stop the customers' production lines," and as a result, automotive lighting equipment lines miraculously resumed production quickly within less than two months.

Hatano Factory Building 2 after the fire

Members of the Restoration Countermeasures Committee giving instructions on emergency measures in response to a fire

The newly completed Hatano Factory Building 2

-

Oct.

Issued bonds with subscription warrant in US dollars and listed on the London Stock Exchange

-

Dec.

Established Asian Stanley International Co., Ltd. (ASI)

The Complete Destruction of the Hatano Factory's Building 2 by Fire

On September 11, 1987, a fire broke out at the Semiconductor Plant 1 in Building 2 of the Hatano Factory. Although there were no casualties, Building 2 was completely burned down. The fire was probably caused by the overheating of parts of photoconductor production facilities.

Immediately after the fire was extinguished, employees carried out restoration work for Building 2 under the slogan of "don't stop the customers' production lines," and as a result, automotive lighting equipment lines miraculously resumed production quickly within less than two months.-

Hatano Factory Building 2 after the fire

-

Members of the Restoration Countermeasures Committee giving instructions on emergency measures in response to a fire

The newly completed Hatano Factory Building 2

-

-

1988

-

Jun.

Launched DN-6, an information system development 6-year plan

-

Jul.

Acquired the management rights for IDESS S.A. of France and renamed it STANLEY-IDESS S.A.S. (SID)

-

Capital stock exceeded 10 billion JPY

-

-

1989

-

-

MR headlamps on the Honda Accord and the Accord Inspire

MR headlamps on the Honda Accord Inspire, the first application

-

-

1990

-

Apr.

Launched rectangular halogen all-glass sealed beams

-